CHANGING

KNIVES

DISCONNECT

POWER

BEFORE

CHANGING

KNIVES!

PLANER

KNIVES

CAUTION;

when

planing

always

back

o

ff

all

four

pressure

screws

to

a

posi on

¼”

higher

than

the

fully

seated

posi on.

You

will

cre

‐

ate

too

much

roller

pressure

and

feeder

problems

if

you

don’t.

Remove

the

chip

extractor

by

pulling

out

the

pin

and

li ing

the

infeed

end

up

fi

rst

and

pulling

it

back

to

clear

the

lips

hold.

Clean

o

ff

knives

and

machine

arbor.

Set

one

knife

at

a

me

in

place

against

the

lip

of

the

arbor.

Place

the

“bevel”

of

the

knife

as

shown

in

the

illustra on

below.

Tighten

the

eight

bolts

securely

using

a

7/32”

allen

wrench.

A er

ghtening,

double

check

to

see

that

the

knives

are

snug

against

the

lip.

MOLDING

KNIVES

Clean

o

ff

knives

and

machine

arbor.

Set

one

knife

at

a

me

in

place

with

the

bevel

edge

posi oned

as

shown

in

the

illustra on

below.

Push

the

knife

fi

rmly

down

against

the

arbor

lip

and

sideways

against

the

bolts

in

the

direc on

of

the

tube

side

of

the

machine.

Hold

secure

while

ghtening

the

bolts.

KNIFE

SHARPENING

For

fast

and

professional

results

with

minimum

edge

loss,

return

your

knives

to

the

factory

for

re

‐

sharpening.

Have

your

knives

re

‐

sharpened

when

you

fi

rst

no ce

some

dullness.

This

gives

op mal

performance

and

maximum

life

span

out

of

the

knives.

Molding

knives

should

be

surface

ground

on

the

face

in

pairs

or

the

pro

fi

les

should

be

reground.

Some mes

it

is

be er

to

regrind

the

pro

fi

le.

If

you

send

them

to

us

for

regrinding,

we

will

use

the

best

method

that

will

prolong

the

use

of

your

knives.

Planing

knives

may

be

ground

on

the

surface

or

on

the

bevel.

Both

molding

and

planing

knives

have

an

edge

angle

of

57

degrees

measured

o

ff

the

back

of

the

knife.

The

use

of

dull

knives

will

put

a

strain

on

the

feed

mechanism

and

will

result

in

your

need

of

a

repair.

Any

problems

created

due

to

the

use

of

dull

knives

are

not

covered

under

the

warranty.

HOW

TO

MOLD

You

will

normally

use

the

guide

sub

‐

plate.

When

using

the

op onal

jig

you

will

take

it

o

ff

.

Always

use

your

sub

‐

plate

on

any

job

where

the

knife

is

designed

to

cut

below

the

bo om

of

the

stock.

This

type

of

knife

will

hit

the

base

of

the

machine

if

a

sub

‐

plate

is

not

used.

An

example

of

this

situa on

would

be

the

molding

of

half

or

quarter

rounds.

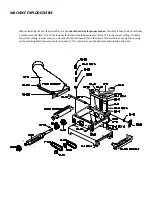

KNIFE

ARBOR

KNIFE BEVEL

INFEED SIDE

OUT-FEED SIDE

VIEW FROM PULLEY SIDE OF MACHINE

ROTATION

Summary of Contents for 20210492060001

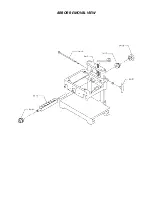

Page 19: ...ARBOR REMOVAL VIEW...

Page 20: ...Stand exploded diagram...

Page 22: ...Notes Maintenance Records...