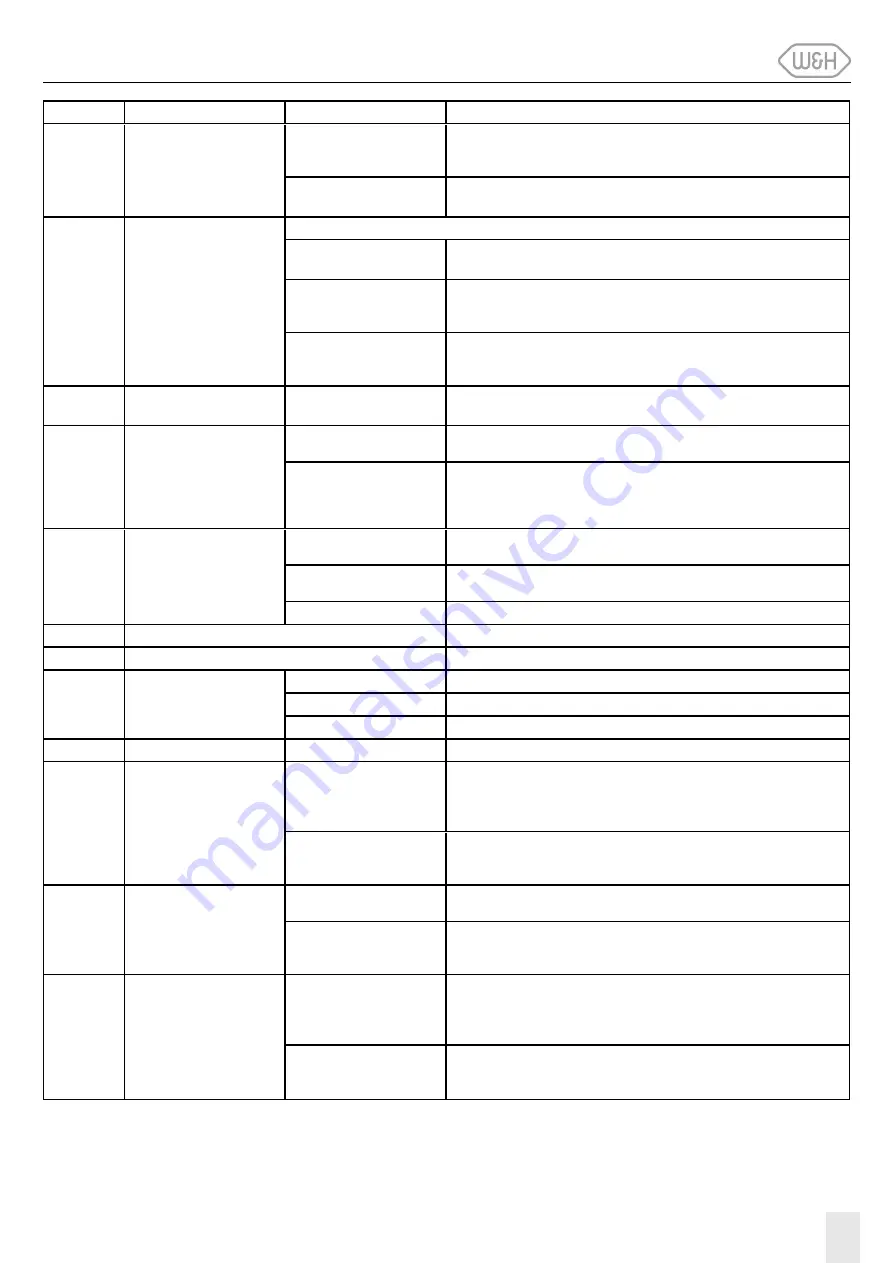

Errors

MN-111 | Service book | Errors and Troubleshooting MN-111 ENG Rev08 | 2019/06/21 | © 2019 W&H Sterilization Srl

13

Code

Description

Possible causes

Checks and actions

181

No temperature decrease at the

beginning of the DRYING phase (in

the first 90”).

Solenoid valve EV1

failure/clogged.

V2 one way valve clogged

Check the components conditions.

Replace the components if necessary.

F1 filter clogged

Chamber filters clogged or dirty.

Check and clean the filters.

Replace the components if necessary.

182

No pressure decrease during the

DRYING phase (if after 10’

Pchamber ≥ Penviroment).

See error "Errors" on page 10, all causes and the following.

Door gasket failure

V2 clogged/dirty

Check the components conditions.

Replace the components if necessary.

F1 filter clogged/dirty

All three chamber filters

clogged/dirty

Check and clean the filters.

Replace the components if necessary.

Pressure sensor failure

See Test instructions service book, chapter SPECIFIC TESTS FOR INDIVIDUAL

COMPONENTS.

Replace the sensor if needed.

183

At the end of the drying phase,

Pchamber > 0.3 bar.

Solenoid valve EV5 failure.

Solenoid valve EV1 failure.

Check the components conditions.

Replace the components if necessary.

205

Chamber heater error (R2 too

low)

Main board failure

See Test instructions service book, chapter SPECIFIC TESTS FOR INDIVIDUAL

COMPONENTS, Chamber heating element and safety thermostat (TABLE POINT 2).

Chamber heating failure

See Test instructions service book, chapter SPECIFIC TESTS FOR INDIVIDUAL

COMPONENTS, Chamber heating element and safety thermostat (TABLE POINT 3).

See Test instructions service book, chapter SPECIFIC TESTS FOR INDIVIDUAL

COMPONENTS, Chamber heating element and safety thermostat (TABLE POINT 4).

206

Chamber heater error (R2 too

high).

Chamber heater thermostat

operated.

See Test instructions service book, chapter SPECIFIC TESTS FOR INDIVIDUAL

COMPONENTS, Chamber heating element and safety thermostat (TABLE POINT 1).

Chamber heater not connected.

Check the connections and the wires between the heater and the main board. If the error

persists, see next step.

Others.

See error "205" above.

207

Chamber heater error (R1 too high).

See error "206" above, but all tests and actions apply to R1.

208

Chamber heater error (R1 too low).

See error "205" above, but all tests and actions apply to R1.

210

Chamber pressure sensor error

or disconnected.

Pressure sensor disconnected.

Check the pressure sensor connections and cables.

Pressure sensor failure.

See error "130" on the previous page, same cause.

Main board failure.

See error "130" on the previous page, same cause.

211

Chamber pressure sensor error.

Pressure sensor failure

See error "130" on the previous page, same cause.

214

Chamber temperature sensor

error.

Chamber temperature sensor

failure.

See Test instructions service book, chapter SPECIFIC TESTS FOR INDIVIDUAL

COMPONENTS, Chamber temperature sensors (TABLE POINT 1 and 2).

If it necessary replace the chamber temperature sensor.

If the problem persists, see next step.

Main board failure.

See Test instructions service book, chapter SPECIFIC TESTS FOR INDIVIDUAL

COMPONENTS, Chamber temperature sensors (TABLE POINT 1 and 3).

If it is necessary, replace the main board.

215

Chamber temperature sensor

error or disconnected.

Chamber temperature sensor

disconnected.

Check the connection to the board and the relevant wires.

Chamber temperature sensor

failure.

Main board failure.

See error "214" above, same causes.

216

Chamber heater sensor error.

Chamber heater sensor failure

See Test instructions service book, chapter SPECIFIC TESTS FOR INDIVIDUAL

COMPONENTS, Chamber heater temperature sensor (TABLE POINT 1 and 3)..

If it is necessary, replace the chamber heater sensor.

If the problem persists, see next step.

Main board failure.

See Test instructions service book, chapter SPECIFIC TESTS FOR INDIVIDUAL

COMPONENTS, Chamber heater temperature sensor (TABLE POINT 1 and 2).

If it is necessary, replace the main board.