12

MN-111 | Service book | Errors and Troubleshooting MN-111 ENG Rev08 | 2019/06/21 | © 2019 W&H Sterilization Srl

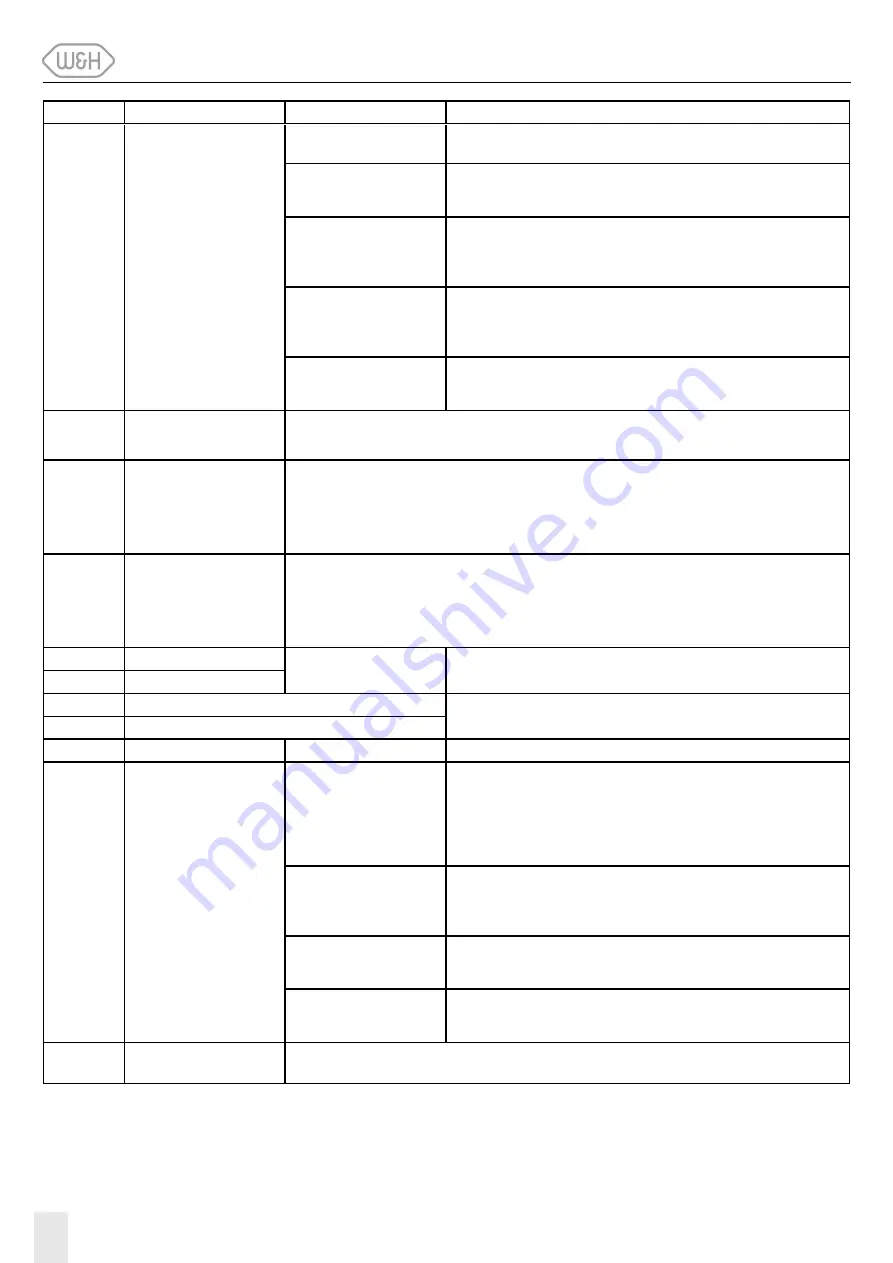

Errors

Code

Description

Possible causes

Checks and actions

130

Theoretical temperature too high.

Chamber temperature sensor

mispositioned.

Check and restore the position of the temperature sensor.

Use the dedicated tool F190100X.

Pressure sensor failure.

See Test instructions service book, chapter SPECIFIC TESTS FOR INDIVIDUAL

COMPONENTS.

Replace the sensor if needed.

Chamber temperature sensor

failure.

See Test instructions service book, chapter SPECIFIC TESTS FOR INDIVIDUAL

COMPONENTS, Chamber temperature sensors.

If the sensor is broken, replace it.

If the error persists, replace the main board.

Steam generator sensor failure.

See Test instructions service book, chapter SPECIFIC TESTS FOR INDIVIDUAL

COMPONENTS, Steam generator temperature sensor (TABLE POINT 1 and 3).

If it is necessary, replace the sensor.

If the problem persists, see next step.

Main board failure

See Test instructions service book, chapter SPECIFIC TESTS FOR INDIVIDUAL

COMPONENTS, Steam generator temperature sensor (TABLE POINT 1 and 2).

If it is necessary, replace the main board.

131

During PR phase the difference

between theoretical and chamber

temperature > 2°C.

See error "130" above, all causes.

132

At the end of HEA2 phase the

difference between theoretical

and chamber temperature >

0,8°C.

(if Tchamaber>Ttheo no error

shown).

See error "130" above, all causes.

133

At the end of HEA3 phase the

difference between theoretical

and chamber temperature >

0,8°C.

(if Tchamaber>Ttheo no error

shown).

See error "130" above, all causes.

140

Theoretical temperature too low

Steam leak.

See error "100" on the previous page.

150

Chamber temperature too low

160

Chamber temperature too high

See error "130" above, all causes.

161

Chamber temperature too high.

163

Chamber pressure too high.

Pressure sensor failure.

See error "130" above, same cause.

164

Safety block during PHE phase.

(Pchamber > 1.4 barA)

EV1 failure

V2 clogged/failure

F1 clogged/failure

All the 3 internal chamber filters

clogged/failure

EV5/EV1 tube line clogged/dirty

Check and clean the chamber filters.

Check the components conditions.

Replace the components if necessary.

Steam generator sensor failure.

See Test instructions service book, chapter SPECIFIC TESTS FOR INDIVIDUAL

COMPONENTS, Steam generator temperature sensor (TABLE POINT 1 and 3).

If it is necessary, replace the sensor.

If the problem persists, see next step.

Main board failure

See Test instructions service book, chapter SPECIFIC TESTS FOR INDIVIDUAL

COMPONENTS, Steam generator temperature sensor (TABLE POINT 1 and 2).

If it is necessary, replace the main board.

Pressure sensor failure

See Test instructions service book, chapter SPECIFIC TESTS FOR INDIVIDUAL

COMPONENTS.

Replace the sensor if needed.

166

Safety block during HEA2 phase.

(Pchamber > 1.9 barA)

See error "164" above, all causes.