WANHAO DUPLICATOR 7

GETTING STARTED GUIDE

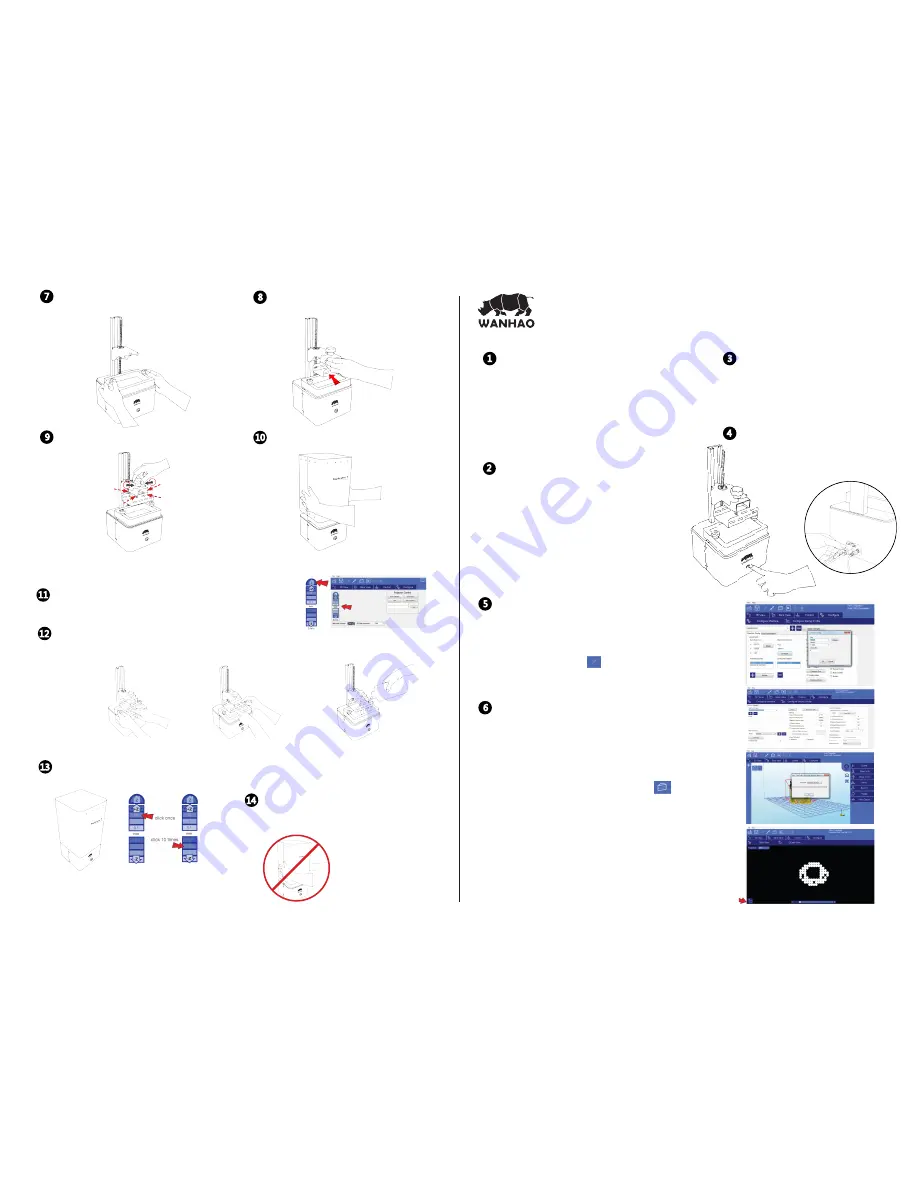

1

DOWNLOAD AND INSTALL SOFTWARE

Go to www.wanhao3dprinter.com and download “Creation

Workshop” and “D7driver_1” located at “Download software—

Duplicator 7”. The latest version is always online.

-Install the driver “D7driver_1” on your computer.

-Execute the Creation Workshop software by clicking on

“CreationWorkshop.exe”

2

UNPACK AND CONNECT CABLES

With the printer switched off, connect:

A.VGA or HDMI cable supplied to the computer and 3D printer.

B.USB cable supplied to the computer and 3D printer.

C.Power cable to the power supply.

3

CONFIGURE SCREEN RESOLUTION

Go to your computer desktop, right click and open

“Screen resolution”. Set your screens to “Multiple

Displays” and “extend this display mode”, keeping

your monitor as the main screen. Video instructions

available at www.wanhao3dprinter.com “Video-

D7”.

4

SWITCH ON PRINTER

Switch on your computer and the switch at front

of printer. Open the software and load the object

(STL,OBJ or AMF)

CONNECT SOFTWARE AND PRINTER

In Creation Workshop, click on “Con-figure”, and then open the subfolder

“Configure Machine”. In the configu-ration folder connect the printer to

the computer by clicking on the button“Configure”. Select the port you

have connected the USB to and set the speed to 115200 and data bits to

8. Press “OK” and finally press “Apply Changes”. To connect your computer

and the the duplicator 7 . .

5

SELECT RESIN AND SLICE OBJECT

Once the object is loaded and located in the build area check the settings

of the printing profile. Go to the “Configure” screen and open the “Configure

Slicing Profile” tab. Select the printing profile from the “Machine Profiles”

list that matches your resin and desired re-solution.

Now click “3D View” and check that the object is correctly placed inside the

printing area. Press the slice button to start the slicing operation.

A confirmation window will appear.

Now open “Slice View” to check that the first layer of every object is in con-

tact with the platform.

6

TIP:

If you experience any issue configuring the screen resolution or usb port, visit

our video tutorial section at www.wanhao3dprinter.com “video”.

Note:

Click here to see the slice view

on the 3D printer screen. Do not

select while a vat with resin is in the

printer or it will cure the resin.

PREPARE DUPLICATOR 7 FOR PRINTING

Place vat on top of the LCD screen and tighten both

Z brackets. If you over-tighten it too much the LCD

screen will go temporarily white. The vat

should not be able to be lifted at all.

7

Side the platform onto the platform arm.

8

Tighten the central knob and loosen the four

screws at the sides so the platform can move freely

up and down.

9

NOTE:

ensure the two side knobs are completely free when

lowering the platform to avoid damage to the screen.

Place the hood back onto the printer

10

Now click on the “Control” tab. Press the “Home” button to lower the

platform onto the screen. The platform will move down to be set on the

screen (level 0 in Z axis.) and stop.

11

Press down on the middle of the Steel platform with one hand and tighten 4 screws

at the side. All 4 screws should now be tight. You can check that you have homed the platform correctly by 11.visual checking

there’s no space between the LCD screen and the build platform. Now turn the screen off before fill the vat with resin. Prints

don't consume a lot of resin, a quarter full vat is enough for a medium sized print.

12

NOTE

: Don’t push the build platform too hard

to avoid breaking the LCD screen. Make sure the

platform touching the screen is sufficient.

NOTE

:once started, the print can’t be paused and refilled

so it's safer to over-fill and reuse the resin.

13

Place the hood back onto the printer. In “Control” panel press +10 button to lift the platform. Once resin is

under the platform, move the platform back to home by clicking the -1 step button 10 times, leave a few seconds

between clicks to enable the resin to move out from under the platform.

Z Axi S

Z Axi S

NOTE:

wait 30sec betwen b and c, to enable resin to move

under the platform. If you miscount it is safer to press an

addi tional step, the platform will not move further when

correctly located.

14

Switch on the screen at the front of the machine.

Now you are ready to print, press “play”. Once the

print ,press "play".Once the print has finished,the

machine will show "print 100% complete"and will

stop.

NOTE:

Don’t remove the hood during

the print or the print will stop.

a.

b.

c.