8

!

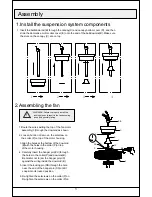

2.Assembling the fan

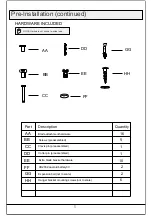

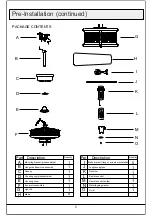

BB

CC

P

D

BB

B

C

E

1

2

3

4

F

Assembly

1.Install the suspension system components

1. Insert the ball/downrod (B) through the canopy(C) and canopy bottom cover (D), and then

slide the decorative motor collar cover (E) onto the end of the ball/downrod(B). Make sure

the slots on the canopy (C) are on top.

DD

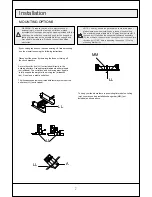

WARNING: Failure to properly install the

locking pin could result in the fan becoming

loose and possibly falling.

1.Route the wires exiting the top of the fan motor

assembly (F)through the downrod as shown.

2.Loosen,but do not remove, the setscrew on

the collar (P)on top of the motor housing.

3.Align the holes at the bottom of the downrod

(B)with the holes in the collar (P)on top

of the motor housing.

4

.

Carefully insert the hanger pin((CC)through

the holes in the collar (P)and downrod(B).

Be careful not to jam the hanger pin(CC)

against the wiring inside the downrod (B).

5

.

Insert the locking pin (DD)through the hole

near the end of the hanger pin (CC)until it

snaps into its locked position.

6

.

Re-tighten the setscrews on the collar (P)on

Re-tighten the setscrews on the collar (P)on