Installation

2021216 [Rev. 2 - en]/2017-04-19

Page 3 | 8

Designation

Use

Chipboard screw

3.5x25 AW20 with

pan head

P1/2.Q.21/22/23:

Mounting frame/pro-

files

Chipboard screw

3.5x15 AW20 with

pan head

P1/2.Q.20/23: Ceiling

profile, clip holder

Chipboard screw

3.5x16 AW20 with

countersunk head

P1/2.Q.20: Fixing

brackets, top/bottom

Tab. 6:

Fixing material on wood (P1/2.Q.20/21/22/23)

Designation

Use

Pan head self-tap-

ping screw DIN 7981

3.5x9.5 AW10

Ceiling profile/clip

holder

Countersunk head

tapping screw

DIN 7982 3.5x13

AW10

Fixing brackets, top/

bottom

Tab. 7:

Fixing material for small parts on mounting frame/

profiles (P1/2.Q.21/22/23)

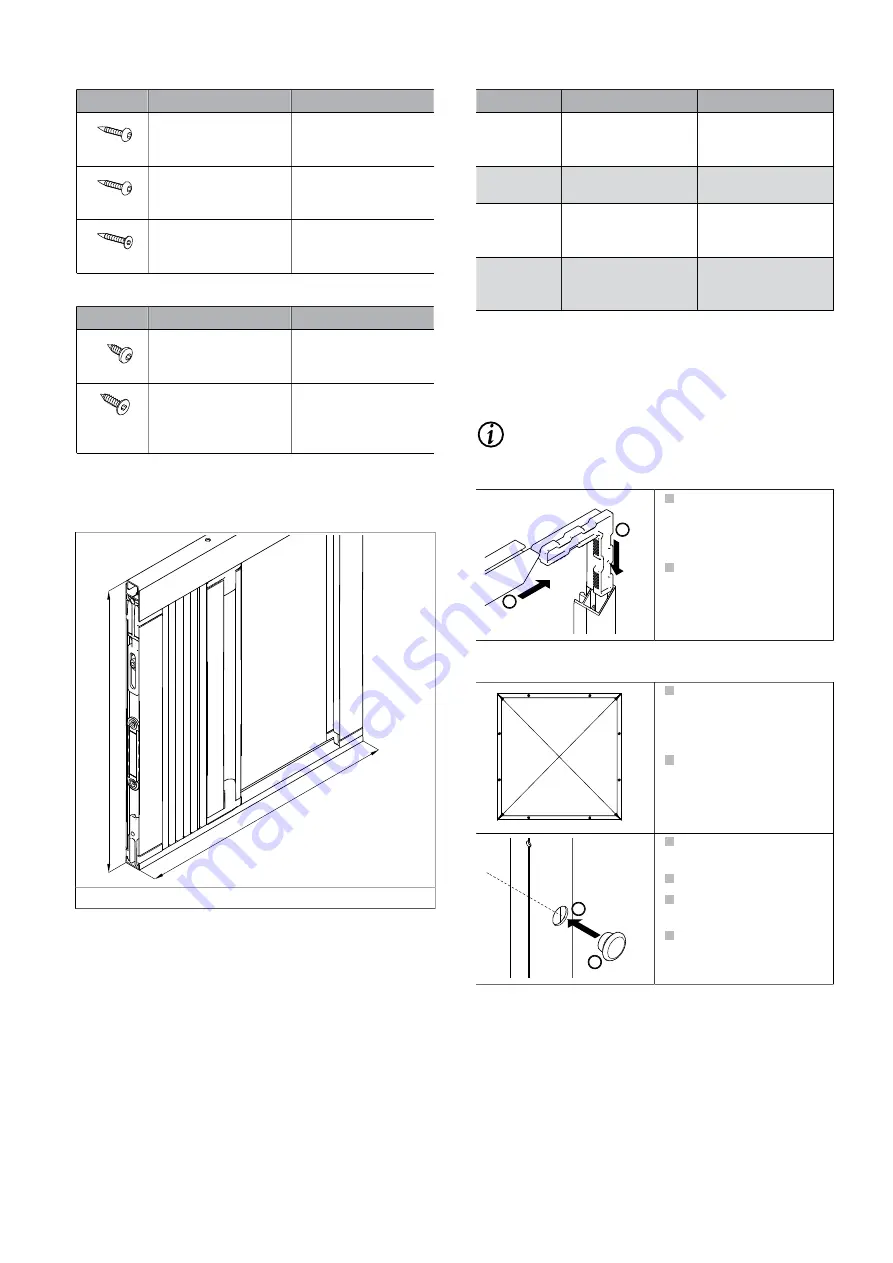

2.2

Product position

B

H

B

Order width

H

Order height

Fig. 2:

Dimensional drawing P1.Q.20

Order width B

Order height H

P1/2.Q.20

Back edge of pack-

age to back edge of

opposite side

Top edge of ceil-

ing profile to bottom

edge of base profile

P1/2.Q.21

Mounting frame di-

mensions

Mounting frame di-

mensions

P1/2.Q.22

Mounting frame di-

mensions

Top edge of mount-

ing frame to bottom

edge of base profile

P1/2.Q.23

Back edge of lateral

mounting profile

Top edge of ceil-

ing profile to bottom

edge of base profile

Tab. 8:

Order width and order height depending on model

2.3

Installing the mounting frame

(P1/2.Q.21/22)

Connecting the mounting frame

INFO

In model P1/2.Q.22, the mounting frame is open at

the bottom.

1

2

Push the corner joint

connector into the

mitres on two mounting

frame profiles.

Slide the mounting

frame profiles (mitre

side) onto the corner

joint.

Attaching the mounting frame

D1

D2

Hold the mounting

frame against the re-

veal. Watch the edge

distances.

Check diagonals D1

and D2. Align the

mounting frame if nec-

essary.

1

2

Transfer the drill hole

position.

Drill the fixing holes.

Attach the mounting

frame.

Press the cover caps in-

to place.