Care/maintenance

[B2000171_1] - EN / 20.12.11

Page 8 of 12

Subject to change without notice.

4.2

Care instructions

To ensure the longest possible life, we rec-

ommend you clean the surface of the product

regularly

or at least once a year.

If the first cleaning takes place years after

initial installation, the product cannot be re-

turned to its original condition.

Replacement claims cannot be honoured on

the grounds of these cleaning and care in-

structions because the effectiveness of these

measures depends on a large number of fac-

tors that vary from case to case.

WARNING

Risk of injury and damage to the product from

inappropriate cleaning!

Do not

use high pressure washers, abra-

sive cleansers, abrasive sponges or sol-

vents such as alcohol or naphtha.

Do

not

support yourself on the product or

parts of the product.

Perform a functional check with the product. Watch

the product as it travels the full range of movement

and look out for any unusual behaviour or noises.

Clean the product regularly (see "Cleaning proce-

dure" table). Lower the black-out blind.

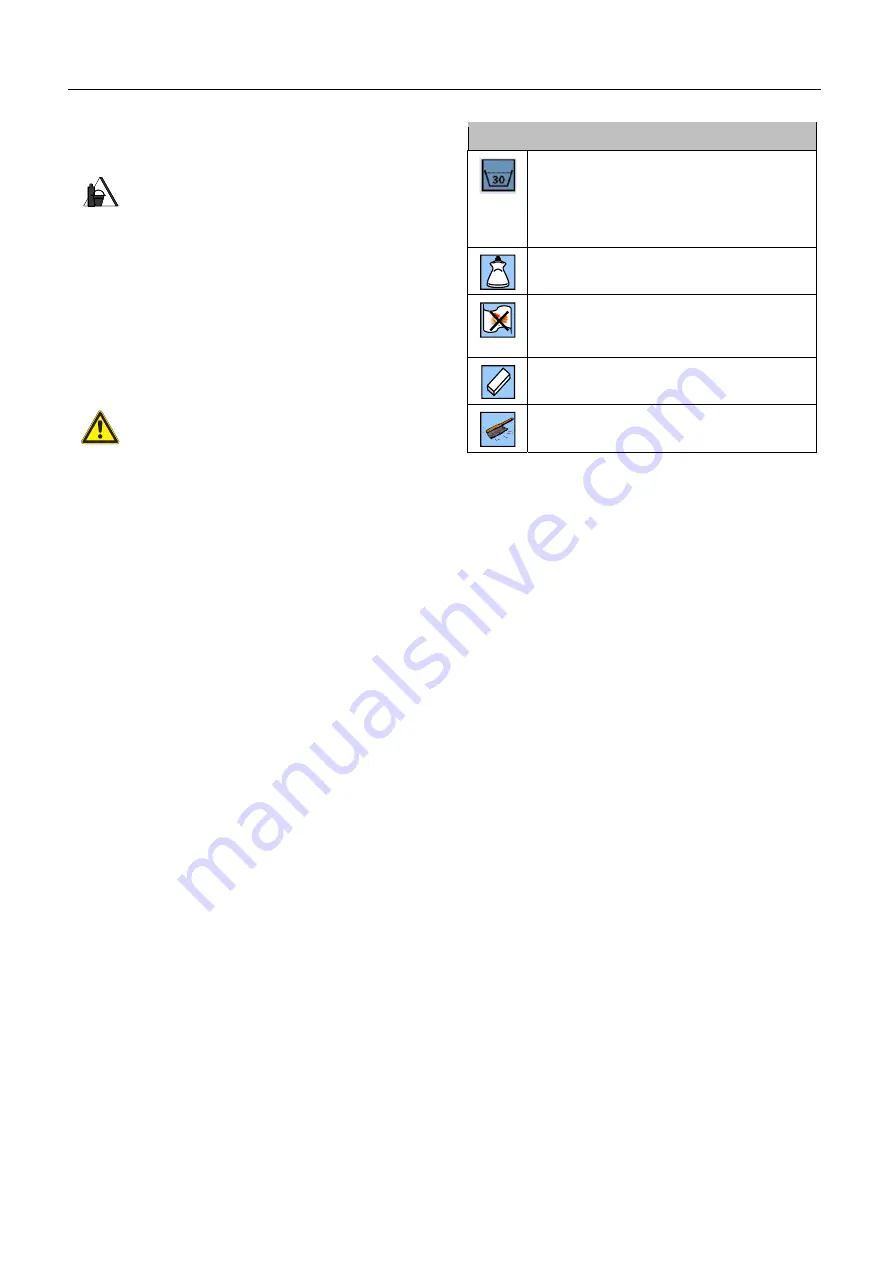

Cleaning procedure

Wash the fabric with a mild detergent solu-

tion (water max. 30°C). A special waterproof-

ing agent has been applied to acrylic fabrics.

This waterproofing layer is diminished every

time the fabric is washed.

Clean the surfaces with a suitable cleaning

agent.

Remove dirt or objects from the product.

Fallen leaves create the conditions neces-

sary for microbial activity.

Use a clear rubber eraser to rub dirty marks

off the fabric.

Brush off the fabric (only for coated polyester

fabrics).

Inspect the operating elements and fabric for visible

wear and damage.

Check the substructure for damage.

Have any damage repaired by a qualified specialist

as soon as possible.

Have any damage repaired by a qualified specialist

as soon as possible. Raise the black-out blind and

take it out of service.