Page:3/5

CAUTION

•

Read the instruction manual carefully prior to operating

•

DO NOT

over load beyond rated capacity

•

ALWAYS

operate truck on ground level

•

Secure the balance of the load

BEFORE

moving

•

DO NOT

fully open the release lever when the trolley is loaded

•

For security

ALWAYS

use the brake system

•

KEEP

foot

OFF

the brake pedal when lowering table

•

The trolley is

ONLY

designed for carrying goods

•

NOT

allowed to carry passengers

•

Equally load goods on the centre of the table before lifting or

lowering

•

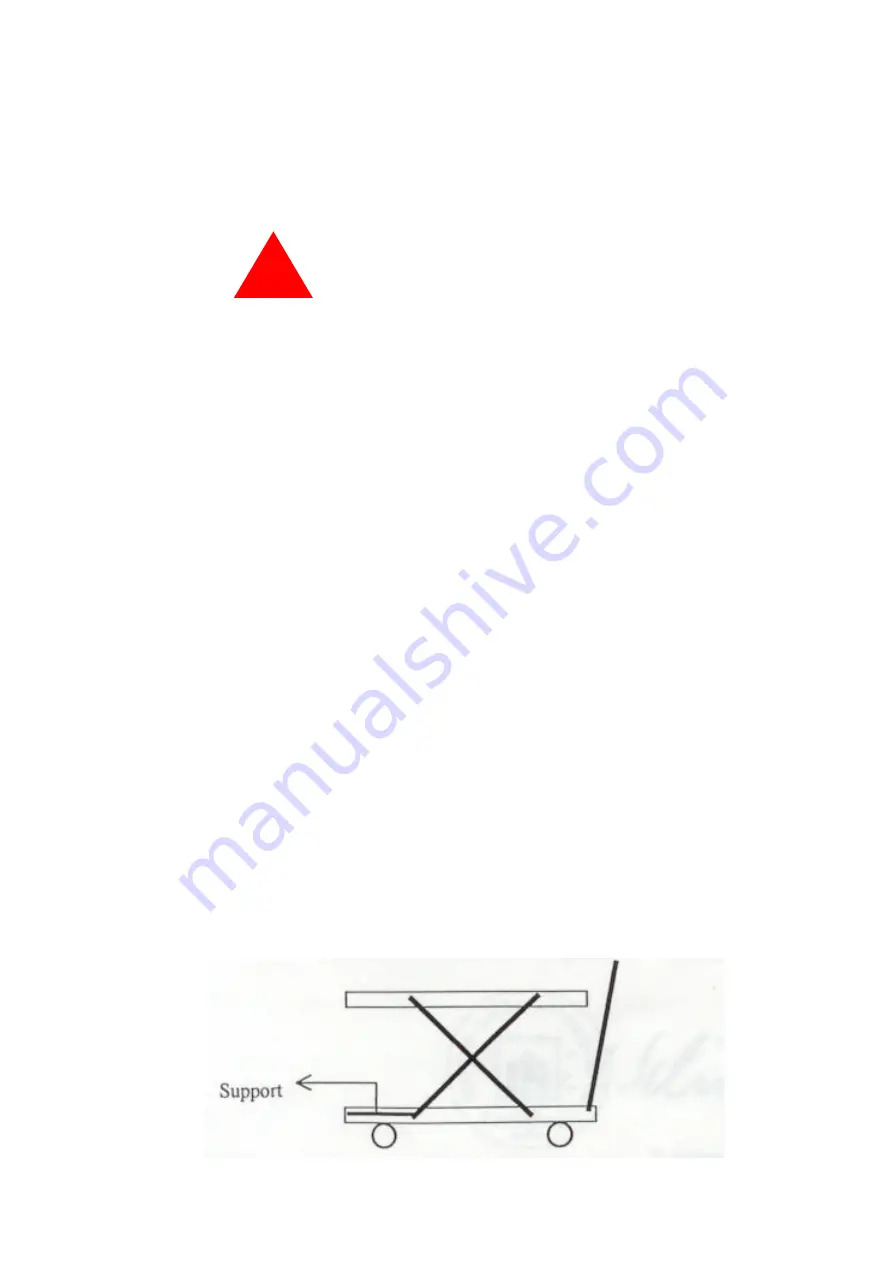

To ensure safety when carrying out maintence ALWAYS lock the

supports.

•

DO NOT

enter under this platform unless it is mechanically locked.

!