5

1.800.556.0595

for assistance

Warmsource-N/P Preparation

INSTALL LOCATION

Before installing Warmsource-N/P, it’s important

to consider its location. Like all gas-fired boilers,

this appliance does make a small amount of noise

which may be disruptive if installed near a bedroom

or common living space. Garages and basements

are the better choice. Installation of a drain pan is

highly recommended.

INSTALLING DISTRIBUTION LINES

After the tubing and manifolds, install the manifold

distribution lines. Sizing, layout and length of the

piping can be found in the WCS Design Drawings.

f

Pressure test all distribution lines for 15 minutes

at 100 PSI (International Mechanical Code,

section 1208.1)

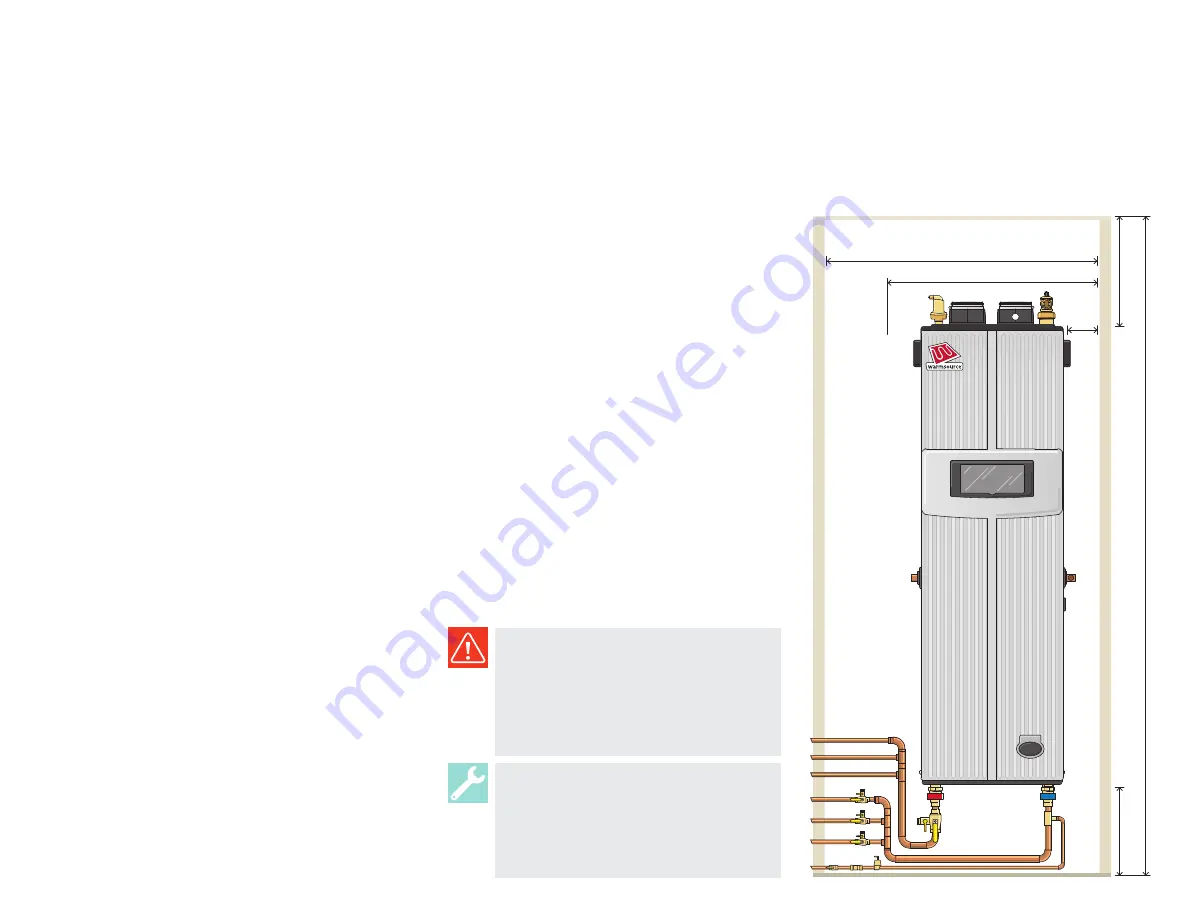

MINIMUM CLEARANCES

This illustration shows the recommended minimum

dimensions for the Warmsource-N/P mechanical

area. This image also depicts the space necessary for

piping and mechanical components. The minimum

depth is 40" for access and serviceability.

18"

46"

32"

3+"

86"

12"

Install the Warmboard-supplied ball valves and

hose bibs and shown in our Design Drawings

for the proper filling and purging of air from

the system.

Pre-plumb boiler components prior to drywall.

Reference page 6 of this guide and/or the

HTP Manual.

Warmsource-N/P cabinet dimensions:

17.5W x 56H x 15.5D

View the boiler page in the WCS Design

Drawings to see how the manifold distribution

lines should be plumbed, and get a better idea

of labor costs.