Page 55

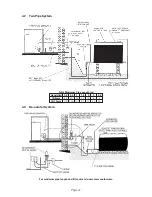

7.2 Sealed Systems

7.2.1 Expansion Vessel

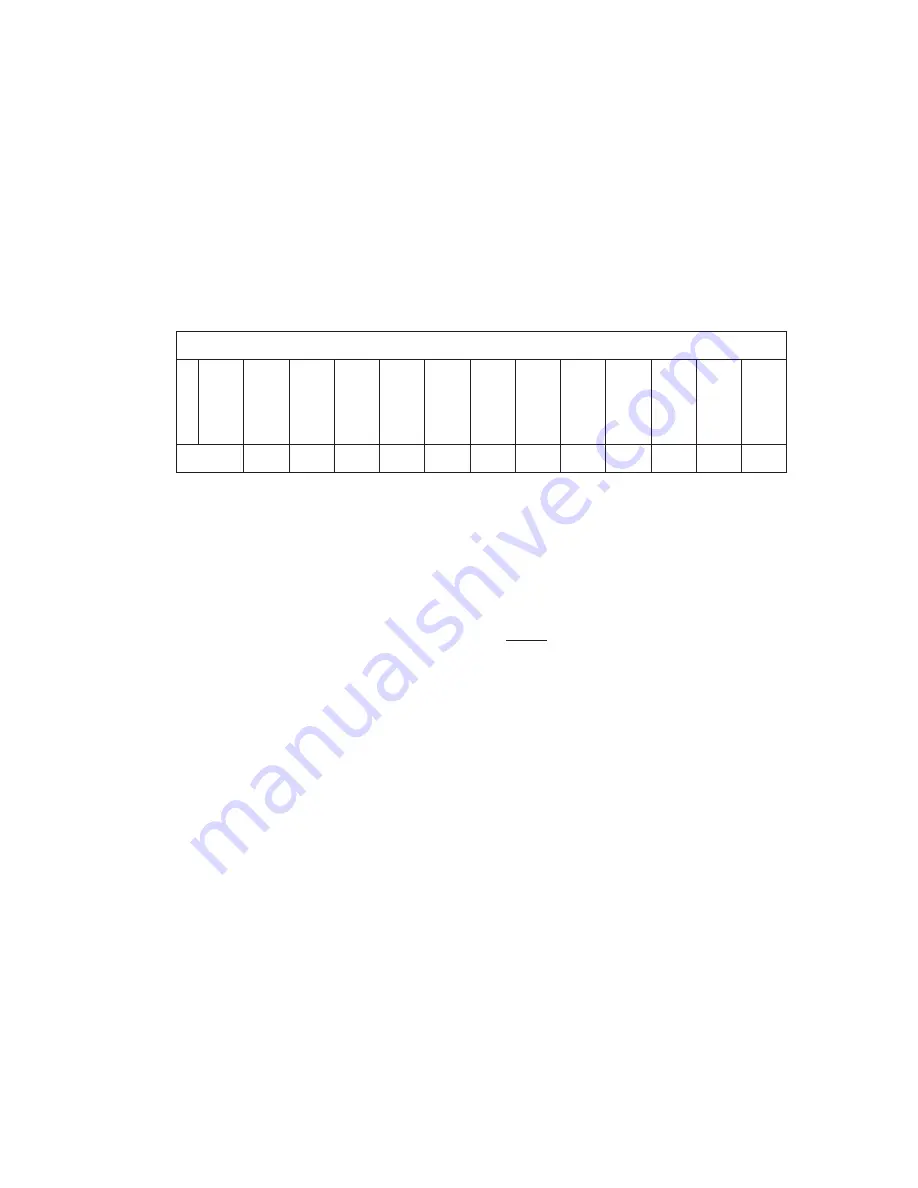

Refer to BS7074: PART and BS5449 for details of expansion vessel sizing. The

values given in the table below are for total system volumes which include the

primary water capacity of the boiler which can be found in the Technical Data section

of this manual. System and Combi models up to 20HE are supplied with a 2 litre

expansion vessel charged to .0 bar. This can accommodate a maximum combined

boiler and system volume of 0 litres. Where permitted by the type, size and

configuration of heating system the expansion vessel bladder pre-charge pressure

can be reduced, prior to filling the system, to 0.5 bar in order to accommodate

a total system volume of 45 litres. If these maximum total system volumes are

exceed, additional expansion capacity will be required.

7.2.2 System Filling

For all System and Combi boilers a filling point complete with a filling loop is supplied

fitted to the expansion vessel. The filling loop

must

be disconnected from the mains

supply after filling. A system pressure when cold of bar is recommended. After

filling, vent all air from the system. The plastic plugs of the auto air vent(s) factory-

fitted to the boiler must be loosened when filling the system in order to bleed the air

from the boiler.

7.2.3 System Pressure

Water loss from the system as indicated by a reduction in pressure on the pressure

gauge may be made up through the filling loop. In the first week of operation it is

normal to see a drop in system pressure. After this time the system pressure must

be rechecked and the system refilled. Failure to do so may lead to boiler faults.

7.2.4 Pressure Relief Valve

Any pressure relief valve fitted to the boiler or system must be able to discharge

externally to a drain where the discharge can be seen but cannot cause any injury

or damage. No other valves should be positioned between the relief valve and

discharge termination.

7.2.5 Low Pressure Switch

Where there is a catastrophic loss of water from the system the boiler thermostats

may fail to operate which would result in serious damage to the appliance. To

prevent this it is recommended that a low pressure cut out switch set at 0.2 bar is

fitted to

the system

and wired in series with the boiler limit thermostat.

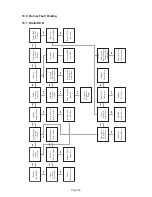

25.0

32.7

46.8

300

VESSEL VOLUMES

22.9

30.0

42.9

275

20.8

27.2

39.0

250

8.7

24.5

35.

225

6.7

2.8

3.2

200

4.6

9.

27.3

75

2.5

6.3

23.4

50

0.5

3.6

9.5

25

8.3

0.9

5.6

00

6.3

8.2

.7

75

4.2

5.4

7.8

50

2.

2.7

2.9

25

0.5

.0

.5

TOTAL SYSTEM

VOLUME

INITIAL

C

HARGE

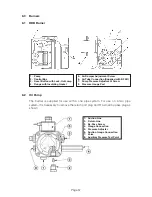

When measuring the expansion vessel bladder pre-charge pressure, using a tyre

gauge, the system should be cold and the system pressure should be relieved (by

manually operating the system pressure relief valve) in order to obtain an accurate

reading.

Summary of Contents for Kabin Pak Combi KC70HE

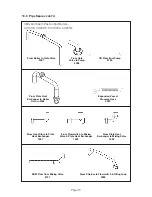

Page 51: ...Page 49 5 0 Flues 5 1 Installation of Flues...

Page 76: ...Page 74 Notes...

Page 77: ...Page 75 Notes...

Page 78: ...Page 76 Notes...