8

warmhaus.com

2.2.9. Radiator and Domestic Hot Water Installations

Radiator and ground heating installation should be constructed in

accordance with technical specifications and heat loss calculation. Radiator

type and amount and ground heating installation pipe amount should

comply with the heat loss calculation.

• Radiator installation should be designed as resisting to at least 6 bars.

• If the city grid pressure is higher than 6,5 bars, pressure reducer must be

installed.

• It is recommended to construct the radiator installation as double line

and without using elbow and joints as much as possible.

• Strainer filter must be installed in radiator return and tap water (city grid)

input line.

• For example; as the radiator cycle's 8 litres expansion (24 kW) tank can

support maximum (80 °C'in radiator system) 140 litre and (55. °C in

ground heating system) 170 litre installation water expansion, additional

expansion tank should be used for larger installation volumes. 170 litre

installation water expansion, additional expansion tank should be used

for larger installation volumes.

• If the room thermostat and thermostatic radiator valve will be used

together; thermostatic valve should not be installed in radiators in the

place where room thermostat is available.

• Cross connection must be made for efficient functioning in radiators

longer than 1,5 m.

• Covers should be used for radiator and domestic hot water wall passages

and fixed with wall clamps to prevent expansions due to heating.

• Combi can function under minimum 0,5 bar domestic hot water pressure

and that corresponds to a very low flow rate and therefore, it shall not

possible to adjust the requested domestic hot water temperature. For

this reason, domestic hot water line should be installed at shortest

distance with pipe having at least ½” internal diameter and by using

elbows as low as possible. At least 1 bar pressurized grid input water

should be supplied to ensure adequate domestic hot water. Hydrophore

should be used if required.

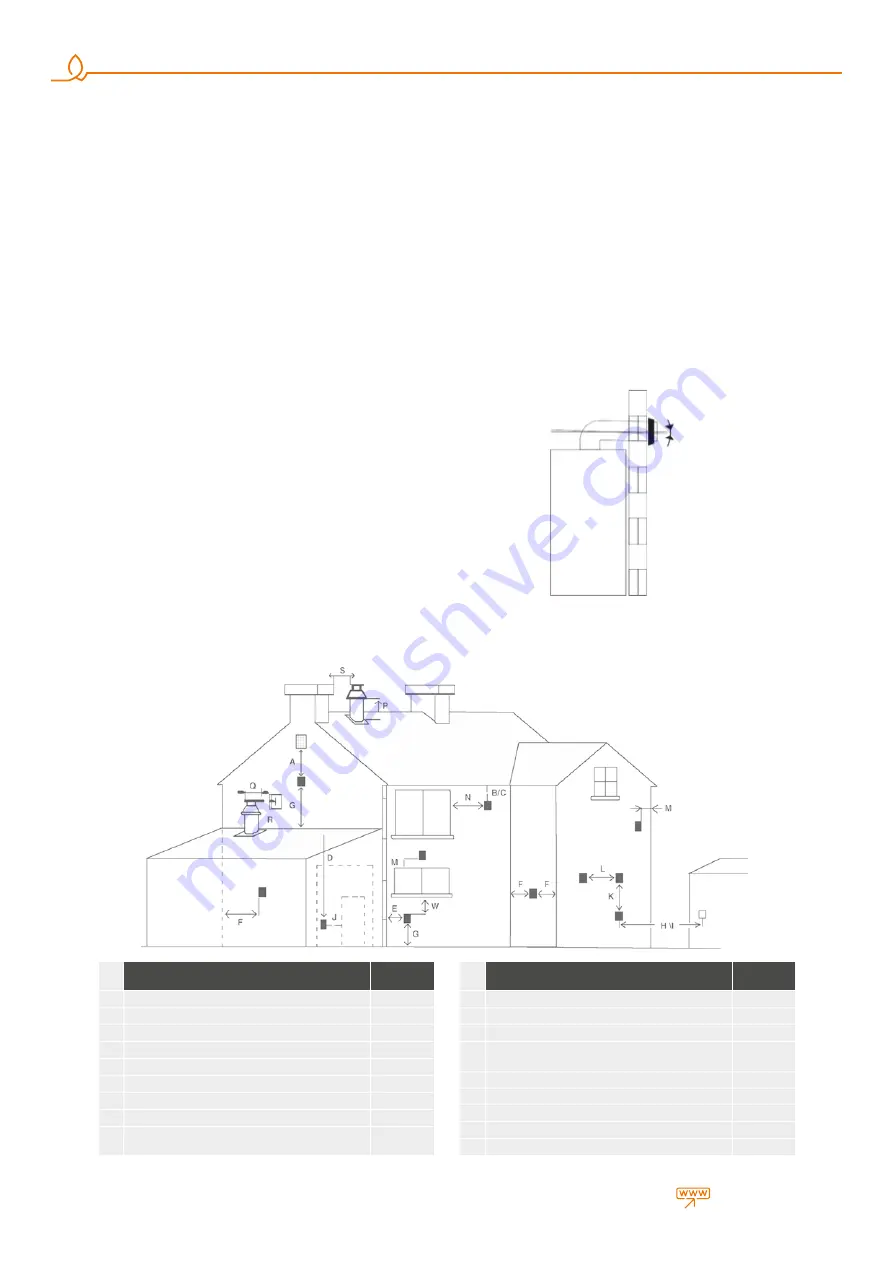

Figure 10

Flue peripheral positions

Flue Position

Minimum

Distance

A

Under a window

300 mm.

B

Under water groove

75 mm.

C

Under fringes

200 mm.

W

Under balconies

200 mm.

E

To vertical water discharge pipes

150 mm.

F

interior or exterior corners

300 mm.

G

At ground, roof or balcony level

300 mm.

H

On another wall corresponding to the flue

600 mm.

S

To another flue

To another wall than the garage wall

1200 mm.

Flue Position

Minimum

Distance

J

To another wall than the garage wall

1200 mm.

R

To another flue than the same wall (vertical)

1500 mm.

Q

To another flue than the same wall (vertical)

300 mm.

M

On another window/culvert

On another window /culvert vertically

300 mm.

P

On the roof level

300 mm.

F

To an adjacent wall

300 mm.

I

To the window on adjacent wall

300 mm.

L

To another flue

1000 mm.

L

600 mm.

Figure 9

Condensing combi flue slope

The air flue terminal

hould be fitted at %3

downwards incline to

prevent any drop or

condensation water

from entering the boiler

Bevel 3°

• Prior to filling the radiator installation, it must be flushed and all wastes

must be cleaned

2.2.10. Exhaust Gas Flue Pipe Set and Accessories Connection

Flue accessory sets to be used in exhaust gas installation of Hermetic combi

boilers should be original Warmhaus flue sets and they should be used

according to installation instructions.

2.2.11. Peripheral Distances of Flue Output Connections

See Figure 10a for placement of flue set output pipe.

Flue should be installed in accordance with national and local directives.

No part of the output pipe or connections should be blocked. If the output

pipe passes 1000 mm nearby of a plastic or painted groove or 500 mm of

painted fringes, an aluminium shield with at least 1000 mm length should

be placed below the groove or fringe. Output pipe should be at least 2 m

over surfaces within reach by individuals.