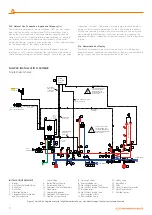

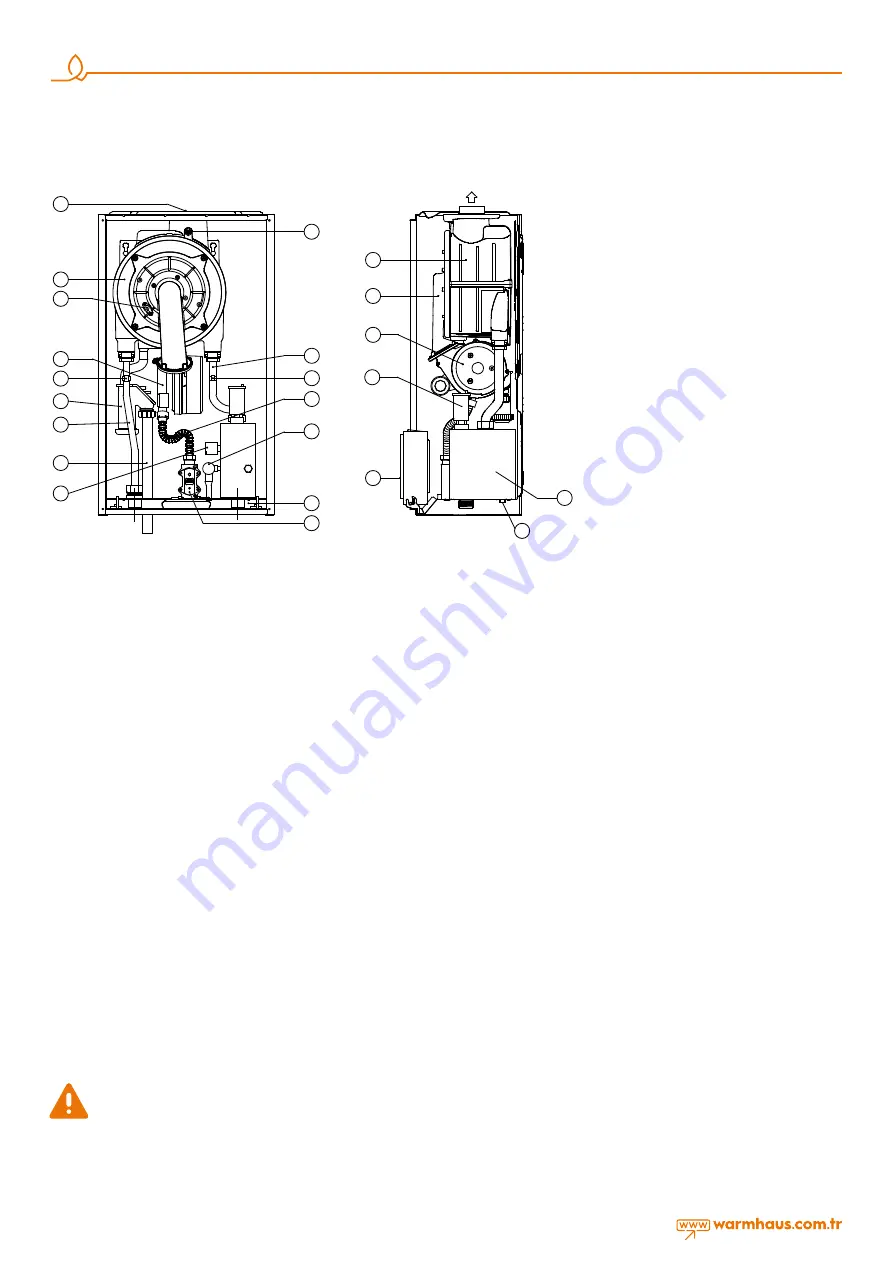

Figure 41

Components of the Boiler

1. Flue Outlet

2. Main Exchanger

3. Ignition Electrode

4. Air-Gas Mixture Unit (AGM)

5. Heating Supply NTC Sensor

6. Condensation Water Flusher

7. Heating Supply Pipe

8. Condensate Water Drainage Hose

9. Low Water Pressure Probe

10. Flue Gas NTC Sensor

11. Gas Supply Pipe

12. Heating Return NTC Sensor

13. 4 bar Safety Valve

14. Manometer

15. Gas Valve

16. Exchanger Cover

17. Electronic Fan

18. Automatic Air Purger

19. Control Panel

22 Heating Return Pipe

21 Strainer Drainage

22 CH Intake Dirt and Air Collector

2.3.1. Components of the Boiler

3. FOR USERS

3.1. GENERAL WARNINGS FOR USERS

3.1.1. Use of the Boiler

If you sense gas odor, first close the gas valves of the boiler and gas

intake line of your house or valves of LPG (LNG) tanks if you use bulk

gas. Do not turn on-off electricity switches, and do not do anything that

may generate sparks. Call gas company or authorized service (See 1.3

Gas leaks)

Start-up of your boiler must be carried out by Warmhaus Authorized

service in order to maintain warranty scope of your boiler. After our

Authorized Service have carried out start-up checks and started your

boiler, they shall inform you about use of the boiler.

Carry out the following checks prior to use:

•

Ensure that; radiator/heating system and gas valves under the boiler

are open,

•

The heating system pressure read on the manometer under the

boiler is between 1 - 1,5 bar, and system air has been purged, boiler

valves are open if there is a boiler connection in the system,

•

There is gas in your gas supply line (you can check by turning on

one of the gas burning appliances),

•

Electrical switch of the boiler is turned on,

•

There are not any flammable materials or products near the boiler,

•

The exhaust gas flue set is not blocked,

•

Room thermostat(s) or control device is at ON position (if

applicable).

•

Follow the procedure given below if you are not going to use, and

shut down the boiler in winter season with frost conditions:

•

Drain the heating system water which does not contain

antifreeze.

•

Turn off the electrical switch, gas valve of the boiler, heating

and domestic hot water!

Follow the steps given below if you are going to turn off the boiler for

a short term:

•

Do not turn off the electrical switch, gas valve of the boiler, heating

and domestic hot water!

•

Leave the boiler in Stand-by (OFF on the display) position, thus Anti-

Frost Function will be enabled.

Turn off the boiler during maintenance and repair operations near

the exhaust gas discharge flues. Have your boiler checked by

Warmhaus Authorized Service prior to turning on the boiler after such

maintenance.

Follow the rules specified below:

•

Do not clean the outer body of the boiler while the boiler is

operating, and do not use flammable materials for cleaning.

•

Do not touch the boiler with wet hands or feet; or with bare hand or

without footwear.

•

Do not pull electrical cables.

•

If the cables are damaged, turn of the boiler and switches, and do

not use the boiler!

•

Electrical cables of the boiler and its accessories shall be replaced

only by the Authorized Service.

•

Do not expose the mounted boiler to any vapors resulting from

cooking.

•

Prevent use of the boiler by children and unexperienced persons.

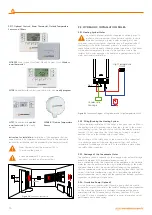

3.2. SELECTION OF ON / OFF / STAND-BY AND

SUMMER / WINTER MODES

Use V circuit breaker (switch) to disconnect the boiler from power

supply. When the appliance is energized, heating temperature on the

left-hand side of the screen and hot domestic water temperature (if

an HDW boiler is fitted) on the right-hand side of the screen shall be

displayed.

3.2.1. On/Off/Stand-by Positions

Use V circuit breaker (switch) to turn on/off power supply connection of

the boiler.

2

4

6

7

9

11

13

17

16

2

19

12

14

1

10

3

5

8

15

1 Flue Outlet

2 Main Heat Exchanger

3 Đgnition Electrode

4 Air gas Mixing Unit (AGM)

5 CH NTC Sensor

6 Condensation Water Trap (Siphon)

7 Radiator Outlet (Flow) Pipe

8 Condensation water Discharge Hose

9 Low Pressure switch

10 Flue Gas NTC Sensor

11 Gas Inlet Pipe

12 CH Return NTC Sensor

13 4 Bar safety Valve

14 Manometer

15 Gas valve

16 Heat Exchanger Door

17 Electronic Fan

18 Automatic air relief Valve

19 Control Panel

20 Radiator Inlet (Return) Pipe

21 Dirt Collector Drain

22 CH Inlet Dirt & Air Collector

20

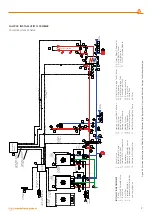

1 Baca Çıkıı

2 Ana Eanjör

3 Ateleme Elektrotu

4 Hava gaz Karıım Ünitesi (AGM)

5 Kalorifer Gidi NTC Sensörü

6 Yoğuma Suyu Sifonu

7 Kalorifer Gidi Borusu

8 Yoğuma Suyu Tahliye Hortumu

9 Düük Su Basınç Anahtarı

10 Baca gazı NTC Sensörü

11 Gaz Giri Borusu

12 Kalorifer Dönü NTC Sensör

13 4 Bar Emniyet Ventili

14 Manometre

15 Gaz Valfi

16 Eanjör Kapağı

17 Elekronik Fan

18 Otomatik Hava Purjörü

19 Kumanda Paneli

20 Kalorifer Dönü Borusu

21 Kir Toplayıcı Drenaj

22 CH Giri kir ve hava kolektörü

21

4 Bar

18

22

22