20

• The maximum permissible sulphate and nitrate content to limit the

microbiologically affected corrosion (MIC) risk is 100 mg/litre.

• Strong oxidizing chemicals should be avoided. Some examples of

oxidizers include, but are not limited to: chlorine (C

12

), hydrogen

peroxide (H

2

O

2

), bromine (Br2), ozone (O

3

), chlorine dioxide (CIO

2

),

sodium hypochlorite (NaClO), potassium hypochlorite lime (Ca

(CIO)

2

). Strong oxidizers are often added as biocides to the water to

reduce microbiological activity of the water.

• Strong complex actuators should be avoided. The most likely

to occur are: chlorides (CI-), ammonia and ammonia containing

chemicals (NH3, amines, EDTA, etc.), polyphosphates (such as

Calgon). Strong complex actuators are also known as “chelates”

(EDTA, NTA), are commonly used to control scaling by typically

forming fixed heat-soluble complexes with calcium and magnesium.

• The installation should be designed so that all air can be discharged,

ensure that all air is discharged after installation. Preferably, you can

also install air separators.

• The total volume VT of water filled, refilled and completely filled

throughout the lifetime of boiler at a total hardness of 11°d or 11°dH

(~2mmol/litre) shall not exceed the following values: 15 litres/kW x

[kW] for Viwa 90-150 series, Taking into consideration that the water

in the installation is likely to be completely filled up several times

over the lifetime of the heat exchanger, the maximum values in the

application must not exceed the following values: 7.5 litre/kW x [kW]

for Viwa 90-150 series.

Example:

Viwa 90 boiler 90 kW, the total volume of the installation is 1100 litres.

The maximum permissible hardness for Viwa 90 can be obtained from

7.5 litres/kW at 11°d.

This is 7.5 x 90 x 11 = 7425 litres. °d

The maximum permissible hardness at 1100 litres, the total volume, is

7425/1100 = 6.8°d.

This means that the water in the installation must be softened to a

value of 6.8ºd or less.

Example 2:

Viwa 150 boiler 150 kW, the total volume of the installation is 5,000

litres. The maximum permissible hardness for the Viwa 150 can be

obtained from 7,5 litres/kW at 11°d.

This is 7.5 x 150 x 11 = 12,375 litres.

The maximum permissible hardness for a total volume of 5,000 litres is

12,375 / 5000 = 2,48 ° d.

This means that the water in the installation must be softened to a

value of 2.48ºd or less.

The following table shows the other examples of maximum water

hardness in °d.

In all cases, the maximum hardness of the water in the installation

must be less than 25°d.

Water treatment

• In the case of water softening by ion exchange, the mixed ion

exchange is preferred. Additional pH buffering should then be

provided.

• Avoid cation exchange with K+ or Na+. If cation exchange with K+

or Na+ is used, pH control is required to limit the pH variation over

time.

• In the case of water softening by anion exchange, only methods

using sulphur (SO42-) as negative ion are allowed. Ion exchange

methods using Cl- or CO32- negative ions are not allowed. If

demineralization is used, a chemical additive will be added for pH

control.

• Never fill the system with distilled water, as this will seriously corrode

the aluminium heat exchanger.

• In order to limit the risk of corrosion, the water conductivity should

preferably be less than 100 μS/cm.

• The conductivity of untreated installation water should not exceed

600 μS/cm.

• If the installation water is treated with one of the products described

below and according to the manufacturer's instructions, the

conductivity must not exceed 1500 μS/cm.

• If the conductivity is higher than the specified values, empty the

system and clean and fill with clean tap water according to EN

14336, preferably with recommended cleaning products.

• There are many products in the market claiming to clean and

protect the heating systems. Unfortunately, there are a few products

that have actually proved this in practice. For this reason, Warmhaus

only allows the following quality products for water treatment;

Manufacturer : Fernox (www.fernox.com)

- Cleaner F3

: Removes corrosion, lime and sludge

- Protector F1 : Protects against corrosion, lime and sludge

- Alphi-11

: Prevents freezing and provides protection

against corrosion and lime

Manufacturer : Sentinel (www.sentinelprotects.com)

- X 100

: General inhibitor protection

- X 200

: Noise reduct

- X 300

: System cleaner for new installations

- X 400

: System renewing sludge cleaning for old installations

- X 500

: Protective antifreeze and general protection

Manufacturer : Clariant (www.antifrogen.clariant.com)

Antifrogen-L : antifreeze (mono ethylene glycol) (Note:

Antifrogen-N is toxic, Antifrogen-L is recommended)

Note that all these products must be used strictly in accordance with

the instructions of the water treatment manufacturers.

We also strongly recommend the following:

• Use a register to fill, refill, completely fill water, water quality

measurements and water treatment.

• Use only non-diffusing material, especially for underfloor heating.

• Always install air discharge devices at the highest point in the

installation.

• In order to avoid as much as possible of filling, refilling and

completely filling, place ball valves near the boiler on the

installation and in strategic locations (anticipating future expansion of

the system).

• Install a water meter to check the amount of filled, refilled, and

completely refilled water.

• Install a filter in return.

• In case of any doubt, install a plate heat exchanger to hydraulically

separate the boiler from the installation.

• Prevent leaks; If there is a leak, repair it as soon as possible.

We recommend that you add this description of the preventive water

treatment to your installation and operating manual.

The above-mentioned water quality requirements apply to aluminium

heat exchangers.

The requirements of other parts in the installation are not taken into

account.

ABD Conversion::

1 litre

= 0,264 USA gallon

1 °dH

= 0,959 gpg

1 kW (NCV)

= 3,792 MBTU/s (GCV)

1 litre/kW

= 0,0697 USA gallon/BTU/s

All information contained in the above descriptions is based on

reasonable research, but does not guarantee any end result.

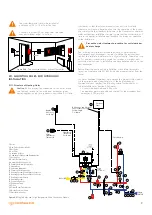

2.11.2. Filling / Emptying Heating System

After installation of the boiler, a supply connection from the network

line must be made with a ball valve with the purpose of filling in

heating installation line to fill the closed-circuit heating installation.