20

Questions? Contact Warming Trends at 303.346.2224

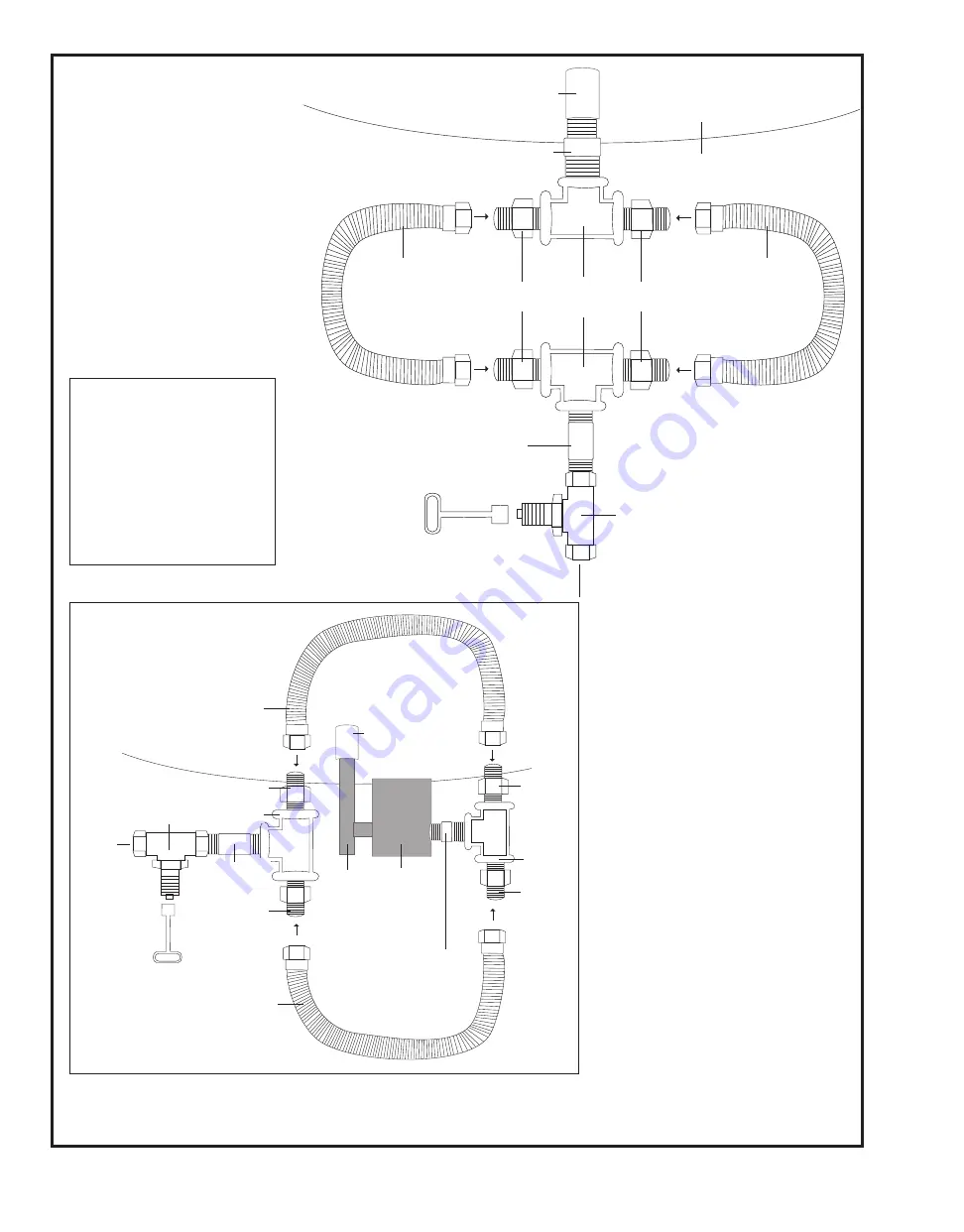

STEP 10A:

Connect

available ends of 3/4”

flex lines (connected to

aluminum plate in Step

6) to 3/4” flared fittings

connected in Step 10.

STEP 10C: (PREMIUM 24 VOLT STANDARD CAPACITY IGNITION)

3” x 3/4”

Nipple

(FIT250)

Drip Leg

Coupling

Premium

24 Volt

Standard

Capacity

Ignition

3/4" Tee

(FIT250)

3/4" Tee

(FIT250)

Flared

Fitting

Flared

Fitting

Flared

Fitting

Flared Fitting

Flex Line

Flex Line

Key Valve

Key In

Gas In

STEP 11: (STANDARD 24 VOLT AND PREMIUM 24 VOLT IGNITION SYSTEMS ONLY)

Plug ignition into three prong, above grade, NEMA Rated, outdoor specific GFCI electrical outlet or have electrician

hardwire ignition into transformer.

FINAL SET UP

Coupling

Flared

Fitting

Flared

Fitting

Flex Line

Flex Line

Plate

Key Valve

Gas In

Key In

3” x 3/4” Pipe Nipple (FIT250)

3/4” Tee

(FIT250)

STEP 10B: (STANDARD 24 VOLT

HIGH CAPACITY IGNITION)

SEE PAGE 20 FOR

INSTALLATION

INSTRUCTION

250K - 299K BTU Systems with DFLKV34 and DFLKV34FIT250

1/2" x 3/4"

Reducing

Fitting (FIT250)

1/2" x 3/4" Reducing Fitting (FIT250)