23 April 2018

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior notifi-

All Dimension are in mm

…….

Copyright on all products and Specifications ©

14

TO THE INSTALLER / GAS FITTER & ELECTRICIAN

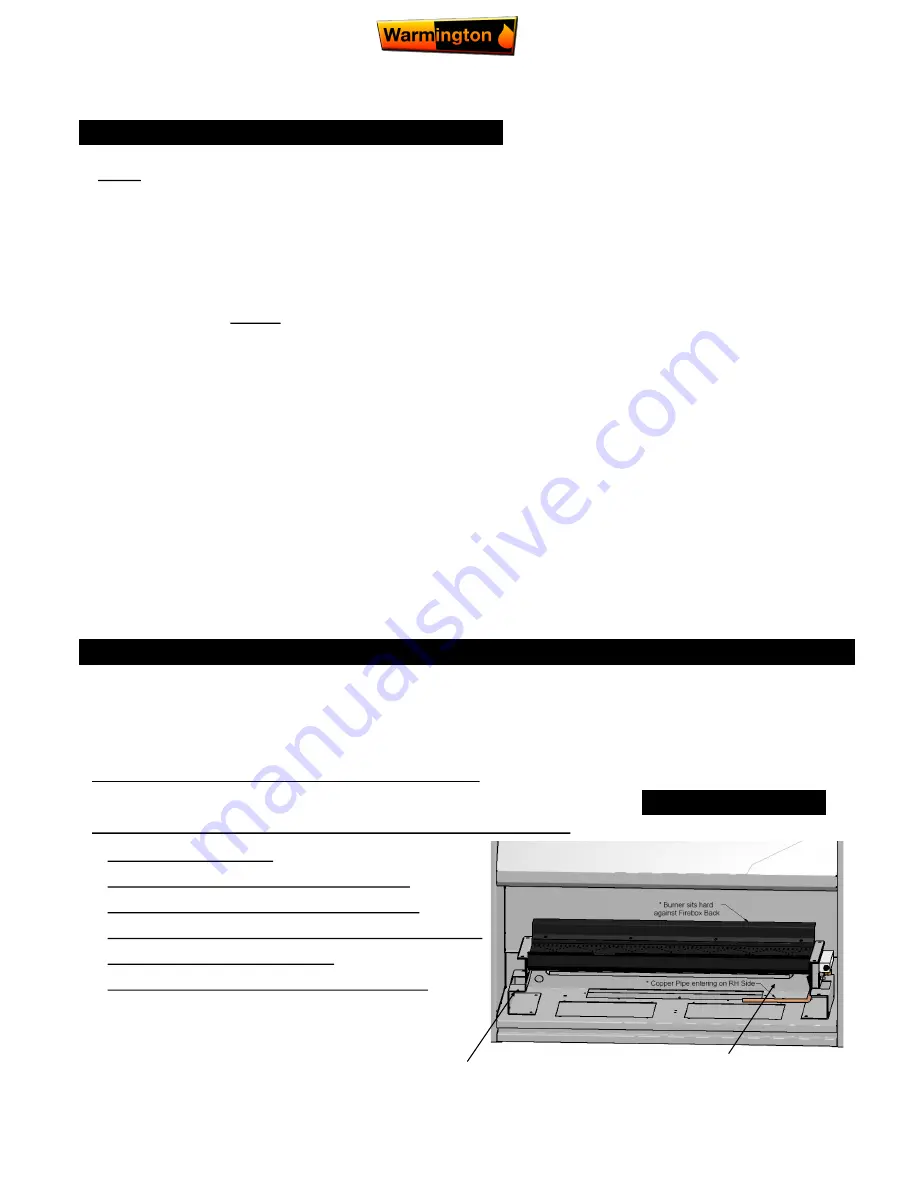

FITMENT OF BURNER

Burner may be

secured

To the Firebox

(Optional)

COMMISSIONING AND TESTING OF FIREPLACE - GENERAL INSTRUCTIONS (To be carried out by Gasfitter)

Read all the instructions before commissioning. Install coals and logs and burner before commission.

Light appliance and check HIGH/LOW settings. Check operation of appliance and adjust to suit.

Adjust control valve setting if required. After a period of running (30min Plus) check the setting of the pilot and adjust if required. See Spec

’

s for details.

Extinguish appliance, remove test equipment and secure test nipple. Check for Gas Leaks.

Note*

The Control Valves are factory set and should not require adjustment.

GAS FITTER TO CARRY OUT STANDARD TESTING FOR COMMISSION:

•

Leak testing appliance & joints

•

Correct operation of the burner and coal and log lay out,

•

Test gas pressures high and low, drop test on supply line,

•

5 second light time across burner, Other testing that may be required.

•

Ventilation requirements to the standards,

•

Hand over to client, tests and comply to relevant standards.

Gas supply pipe into fire,

by Gasfitter. See spec

’

s for

pipe sizes.

NOTES:

•

Service annually or more if required.

•

Custom built to clients requirements to relevant and current standards.

•

The appliance and flue system must be installed in accordance with the relevant and current standards and the appropriate

building codes.

•

The appliance and flue system must be tested in accordance with the relevant and current standards and the appropriate

building codes.

FLUED GAS APPLIANCES

All Gas Fires requiring Warmington Flue Systems shall be Installed to the requirements of the current standards and shall

be appropriately designed and constructed to permit safe and effective use. This Appliance must be flued to the outside atmosphere. All Warmington

Fires must be Installed with a

minimum of 3.6m

of Approved

Warmington Gas Flue and Liners

. (Flueless Gas Fires Do Not Have Flue)

GAS TYPE

All Gas Fires shall operate safely on the Gas Type specified on the Appliance and shall comply with the requirements of The Gas Act

1992 .

APPLIANCE SAFETY

Any gas fire appliance shall comply with the safety requirements of the current standards listed under

“

Related documents

”

in

this specification.

ELECTRICAL REQUIREMENTS

All Gas Fire Appliances Installed with Mains Supplied Electrical components for associated use with these Applianc-

es, must comply with The Electricity Regulations 1993.

ELECTRONIC CONTROL SYSTEMS

Any Gas Fire Appliance Installed with Manual or Programmable Electronic Control System shall be tested and/or

approved by a Recognised Person or Authority.

SEISMIC RESTRAINTS

All Fires used for Domestic and Commercial Purposes shall be firmly secured (unless defined as portable or mobile) to pre-

vent dislodgement from their point of fixture or Installation during Seismic Activity. Such Restraint must be of a reasonable expectation .

GAS CONNECTION

A Gas Certificate must be obtained for the Installation and Commissioning of this Appliance and Flue System. (If Required)

Check that the Gas Type Specified on the Data Plate is correct for the available supply (LPG or NG).

A Copper Gas supply capable of supplying the correct MJ/h , should be brought into the rear of the Installation Cavity through the hole provided. A

Flare Nut is provided on the Burner for Gas Connection to the Appliance.

SG Burner Range Only: Gas Nouveau Outdoor Fireplaces