17 October 2014

All Dimension are in mm………….Copyright ©

6

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior notification.

Note:

Wet back can NOT be

fitted to fires that are

installed in any area

that falls under clean air

regulations.

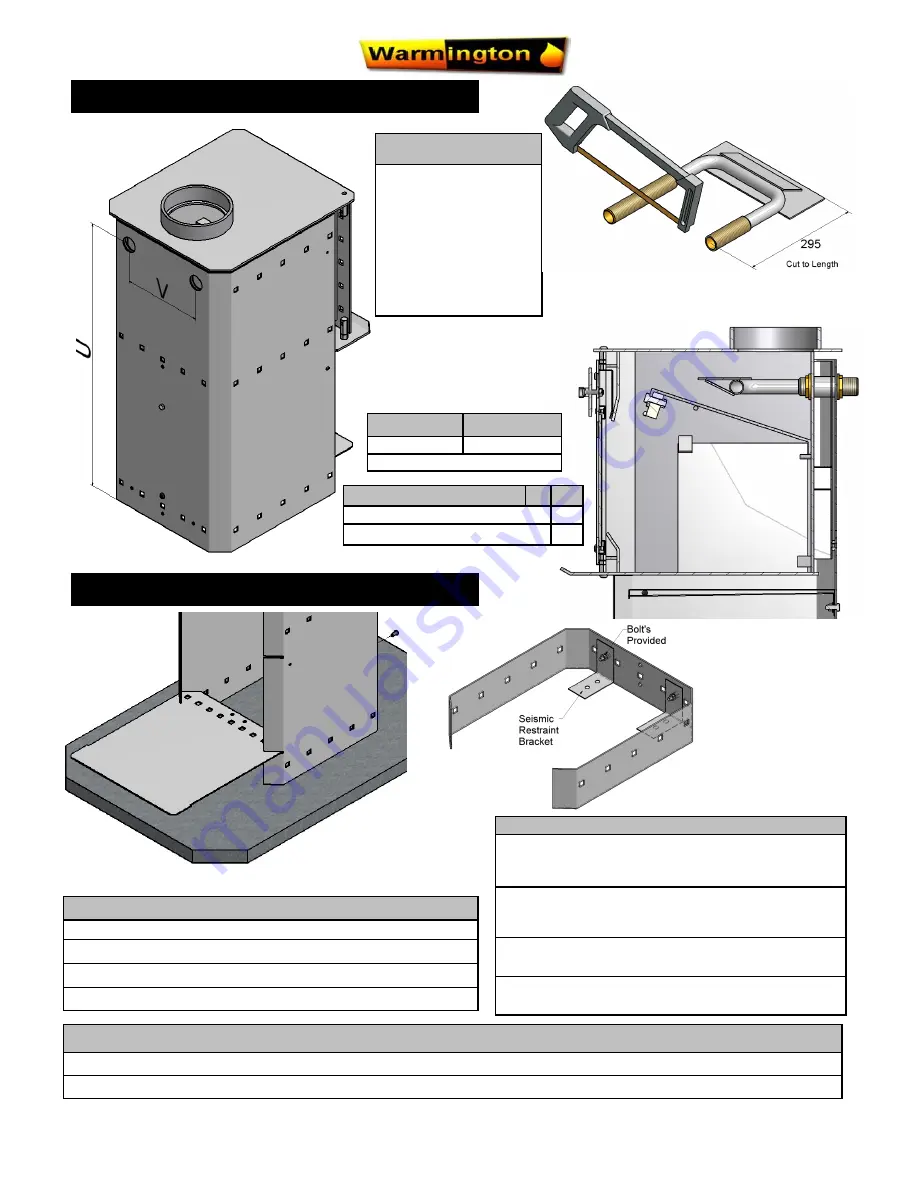

Cut Excess BSP pipe

off

wet

back

to

length…..By Plumber.

Description

Height from Bottom of Unit

U

750

Distance Between Outlets

V

220

Power Out

KW*

Wetback

-

*Value is approximate”

Note:

Consult your plumber for wet back system configurations and operation.

Wet back is to be fitted to an internal heat-sync (e.g. Hot water cylinder / Radiator / Under floor heating etc…

WETBACK POSITION

SEISMIC RESTRAINT FIXING

Seismic Restraint Fixing Instructions

Remove Bottom Tray . (Remove bolt at back of tray & slide shelf out)

Fit Seismic Restraint Brackets .(2 at rear unit)

Fix Bracket into Floor through the Hearth .

Replace Bottom Shelf and Bolt back on .

Seismic Restraint Fixing Instructions

Fix 2X Seismic Restraints through the Hearth into

the Floor . They are to penetrate into the fixing by at

least 3 times their diameter.

Use at least 2 x 6 to 8 mm Dia Dyna Bolts or similar

to fix fire to hearth and or through the hearth to the

floor.

Fix hearth to floor with appropriate adhesive , bolt

or screw.

Ensure that the Seismic Restraint complies with

ASNZS 2918:2001— Ref 3.8