WARN INDUSTRIES

13

FIRST TIME OPERATING INSTRUCTIONS

Step 3 - (Optional) Synthetic Rope

Installation

For synthetic rope models, be sure to fully read

the WARN Synthetic Rope Installation Instruction

manual for detailed synthetic rope installation

instructions.

Step 4 - System Check

1. With clutch engaged, power-in winch rope

while making sure drum is turning in the

proper direction.

2. Once you have confirmed winch rope is

winding on the drum in the correct direction,

continue to power-in the rest of the winch

rope.

11. Installation complete. Move on to First Time

Operating Instructions.

Step 5 - First Time Operating

Instructions

In this section, we’ll show you the first

time operating instructions for effective basic

winch ing. For complete winch operation and

techniques read the Basic Guide to Winching

Techniques found online at http://www.warn.

com/corporate/literaturerequest.shtml.

Remote Control

The winch is controlled by the hand held

remote control. The remote control provides

control of the power-out (forward) or power-in

(reverse) rotation of the spooling drum.

Do not leave the remote plugged into the

winch when not in use. Leaving the remote

plugged in, may result in a dangerous condition

and/or battery drain.

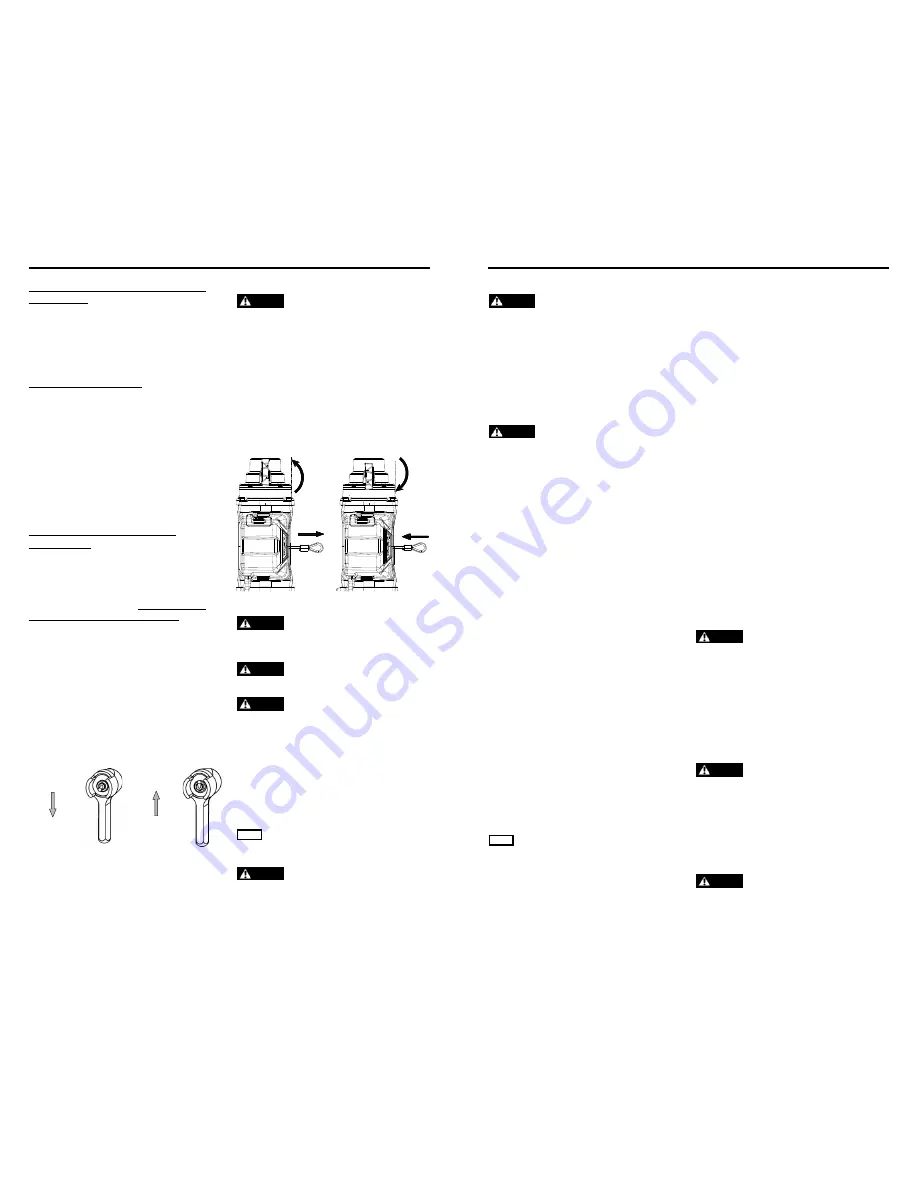

Clutch Operation:

WARNING

Never engage or disengage clutch if winch is

under load, winch rope is in tension or drum is moving.

When the clutch is engaged, the gear train

is coupled to the winch drum and power can

be transferred from the winch motor. When the

clutch is disengaged the drum is in the freespool

position and the gear train and winch rope drum

are uncoupled allowing the drum to rotate freely.

The clutch lever, located on the winch housing

opposite the motor, controls the clutch position.

To prevent damage, always fully engage or fully

disengage the clutch lever.

Spooling Out

WARNING

Never operate winch with less than 5 wraps

of rope around the drum. Rope could come loose from the

drum, as the rope attachment to the drum is not designed

to hold a load.

WARNING

Always keep hands clear of winch rope,

hook loop, hook and fairlead opening during installation,

operation, and when spooling in or out.

WARNING

Always wear heavy leather gloves when

handling winch rope.

Freespooling is generally the quickest and

easiest way to spool out winch rope. Before

freespooling winch rope out from the winch,

power out enough rope to remove any tension

the winch rope might be under. Disengage the

clutch. Then freespool by manually spooling out

enough winch rope for the winching operation.

See The Basic Guide to Winching Techniques for

more information.

NOTICE Do NOT power out more than 30ft without allowing

the winch to cool for 20 minutes before powering rope back in.

Instead, place the clutch in freespool and pull the rope out by hand.

WARNING

Always use supplied hook strap whenever

spooling winch rope in or out, during installation or

operation to avoid injury to hands and fi ngers.

Power Out

Power In

Standard remote control switch

DISENGAGED

ENGAGED

WARN INDUSTRIES

14

FIRST TIME OPERATING INSTRUCTIONS

Spooling In Under Load

WARNING

Never exceed winch’s rated line pull.

Power-in the winch rope evenly and tightly on

the drum. This prevents the outer winch wraps

from sinking into the inner wraps, binding, and

damaging the winch rope.

Avoid shock loads when spooling, by pulsing

the control switch to take up winch rope slack.

Shock loads can momentarily far exceed the

winch and rope ratings.

Spooling In Under No Load

WARNING

Never touch winch rope or hook while

someone else is at the control switch or during winching

operation.

Spooling with an Assistant

: Have the assistant

hold the hook strap putting as much constant

tension on the winch rope as possible. While

keeping tension, the assistant should walk toward

the winch while you operate the control switch

spooling in the winch rope. Release the switch

when the hook is a minimum of 6 ft. (2m) from

the fairlead opening.

Spool in the remainder for storage as directed

below.

Spooling Alone

: Arrange the winch rope to

be spooled so it will not kink or tangle when

spooled. Be sure any winch rope on the drum is

tightly and evenly layered. Spool enough winch

rope to complete the next full layer on the drum.

Tighten and straighten the layer. Repeat process

until the hook is a minimum of 6 ft. (2 m) from the

fairlead opening.

Spool in the remainder for storage as directed

below.

Spooling Remainder for Storage

When the hook is within 6 ft. (2 m) of the fairlead,

disconnect the hook from the anchor or load.

Hold onto the supplied hook strap and hold

tension on the winch rope. Slowly power-in the

winch by “pulsing” the power-in switch on the

remote control until the hook is within 3 ft. (1 m)

of the fairlead.

Stop winching in and attach the hook to a

suitable anchor point on the vehicle.

NOTICE Do not power the hook into the fairlead. This could

cause damage to the fairlead.

Once the hook is suitably attached to the

vehicle, power-in the remaining slack in the

winch rope by “pulsing” the power-in switch on

the remote control until there is minimal slack in

the winch rope.

Overloading/Overheating

This winch is rated for intermittent duty.

When the motor approaches stall speed, very

rapid heat buildup occurs which may cause

motor damage.

Double-line rigging (see The Basic Guide to

Winching Techniques) will reduce the amperage

draw, and reduce heat buildup in the motor. This

allows longer continual use.

STRETCHING WINCH ROPE

Stretching (tensioning) the winch rope is

critical to ensure a long product life. Tensioning

the winch rope will prevent outer layers of winch

rope from pinching and deforming the inner

layers.

During its first use, a new winch rope must be

spooled onto its drum under a load of at least

1000 lbs. (454 kgs).

Use the following instructions to properly

stretch the winch rope onto the winch drum.

1. Choose

a

FLAT AND LEVEL

location that is

large enough to run out almost the entire

length of winch rope.

2. Disengage clutch.

WARNING

Always keep hands clear of winch rope,

hook loop, hook and fairlead opening during installation,

operation, and when spooling in or out.

3. Grasp hook strap and spool out the winch

rope to the last 5 wraps on the drum (10

wraps if synthetic rope).

4. Once the winch rope is spooled out, engage

clutch.

5. Attach the hook end of the rope to a suitable

anchor point.

WARNING

Always be certain the anchor you select will

withstand the load and the strap or chain will not slip.

6. Return to your vehicle.

7. Back the vehicle away from the anchor point

until there is very little slack in the winch

rope.

8. Set the parking brake, place the vehicle in

gear or park and turn the vehicle off.

WARNING

Always stand clear of winch rope and load

and keep others away while winching.

97003A0

97003A0