OPERATING INSTRUCTIONS

7

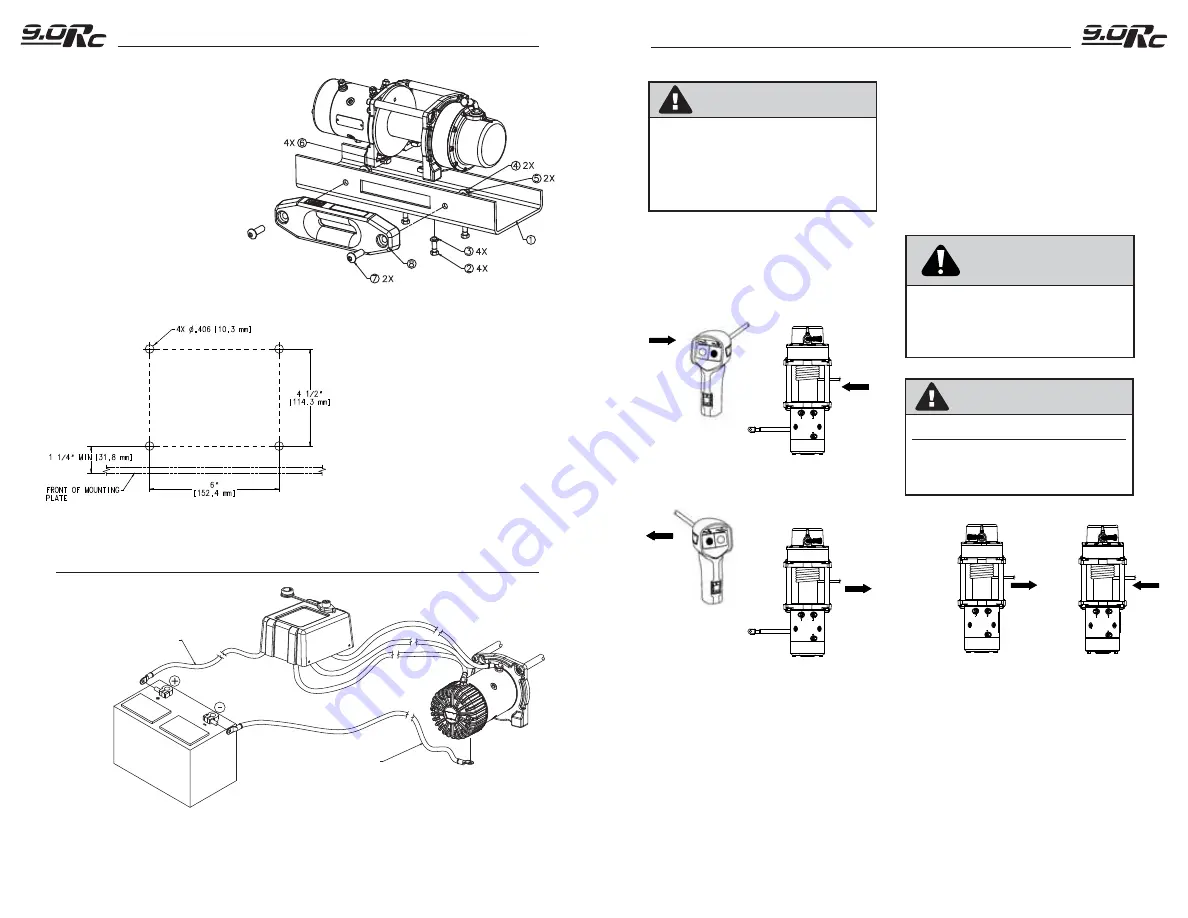

CLUTCH OPERATION

When the clutch is engaged the gear train is coupled

to the rope drum and power may be transferred

from the winch motor. When the clutch is in free

spool the gear train and rope drum are uncoupled

allowing the drum to rotate freely. The clutch knob,

located on the winch housing opposite the motor,

controls the clutch position. To prevent damage,

always fully engage or fully disengage the clutch

knob.

REMOTE CONTROL SWITCH

Do not leave the remote plugged into the winch

when not in use. Leaving the remote plugged in, may

result in a dangerous condition and/or battery drain.

ENGAGED

DISENGAGED

WA R N I N G

Never leave clutch disengaged when not

freespooling rope. The automatic brake

will not operate when clutch lever is in

freespool.

Mounting requirement & hardware:

(1)

Smooth and flat, thickness = 1/4" (6.35 mm)

(2)

3/8" (9.5 mm) lockwasher X 4

(3)

3/8-16 X 1 1/4" long grade 5 bolt X 4,

torque 30-35 ft. lbs. (41-47 Nm)

(4)

1/2-13 Locknut

(5)

1/2 Flat washer

(6)

3/8-16 Sq nut

(7)

1/2-13x2" button head bolt

(8)

Aluminum Fairlead

INSTALLATION INSTRUCTIONS

6

ELECTRICAL CONNECTIONS

RED CABLE (183 cm)

BLACK CABLE (72”)

BATTERY

Mounting bolt pattern:

6.0" x 4.5", 152.4mm x 114.3mm

OVERLOADING/OVERHEATING

This winch is rated for intermittent duty. When the

motor approaches stall speed, very rapid heat

buildup occurs which may cause motor damage.

Double-line rigging (see Basic Guide to Winching

Techniques) will reduce the amperage draw, and

reduce heat buildup in the motor. This allows longer

continual use.

LINE

IN

REMOTE

CONTROL

SWITCH

REMOTE

CONTROL

SWITCH

LINE

OUT

ALWAYS KNOW YOUR WINCH: Take time

to fully read and understand the included

Installation and Operations Guide, and

Basic Guide to Winching Techniques, in

order to understand your winch and the

winching operation.

• Never engage or disengage clutch if

winch is under load, wire rope is in

tension or wire rope drum is moving.

To avoid minor or moderate injury:

C A U T I O N

C A U T I O N