4. Prevent the machine from water entering or being affected with damp,

otherwise dry it by blowing and examine the insulation condition with a

megohmmeter (both between the connected nodes and the between the

connection points and the casing). Welding cannot be continued unless no

abnormal circumstance is found.

5. If the welding machine will be disused for a long time, it should be put into

the original packaging and stored in a dry environment.

6. Troubleshooting

Note: The following operation requires that the operator have enough

professional knowledge on electricity and overall elementary knowledge of

safety. The operation should have the qualification certificate that can

prove his ability and knowledge.

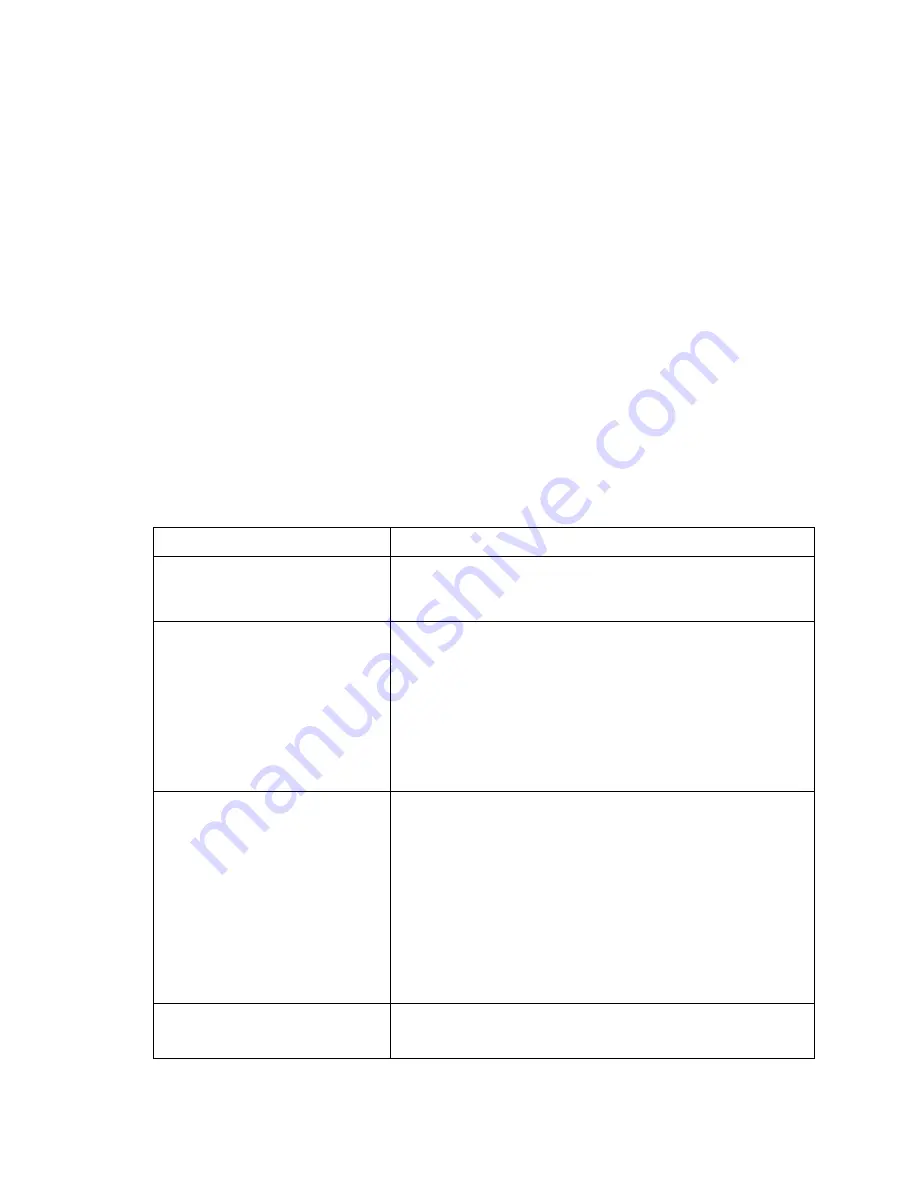

Troubleshooting for LGK-40:

Faults Correction

actions

The power LED shines

The fan does not rotate and the

control button is out of control.

Overvoltage protection. Turn off the machine and wait for a

moment. Then restart the machine.

The power LED shines.

The fan rotates. If the control

button of the cutting torch is

pressed, the electromagnetic

valve acts without the sound of

high frequency arc striking

discharging, and the red LED

inside the machine shines.

1. The MOS field effect tube K1170 of the upper board is

damaged (the driving module is damaged).

2. The step up electric transducer is damaged.

3. The control module is damaged.

The power LED shines.

The fan rotates. If the control

button of the cutting torch is

pressed, the electromagnetically

operated valve acts without the

sound of high frequency arc

striking discharging, and the red

LED inside the machine does not

shine.

There is something wrong with the arc striking part:

1. The distance of the discharging nozzle may be too long or

there may be edge adherence phenomenon.

2. There may be the phenomenon of open circuit or loose

contact in the primary coil of the arc striking transformer.

3. The quadruple voltage rectifier diode may be sparked

over.

4. The high frequency capacitor 102/10KV may leak

electricity.

5. The relay may be damaged.

Arc cannot be stricken during

welding, and the else is normal.

1. The input voltage is too low.

2. The pressure of the air compressor is too high or too low.

Summary of Contents for LGK-40

Page 11: ......