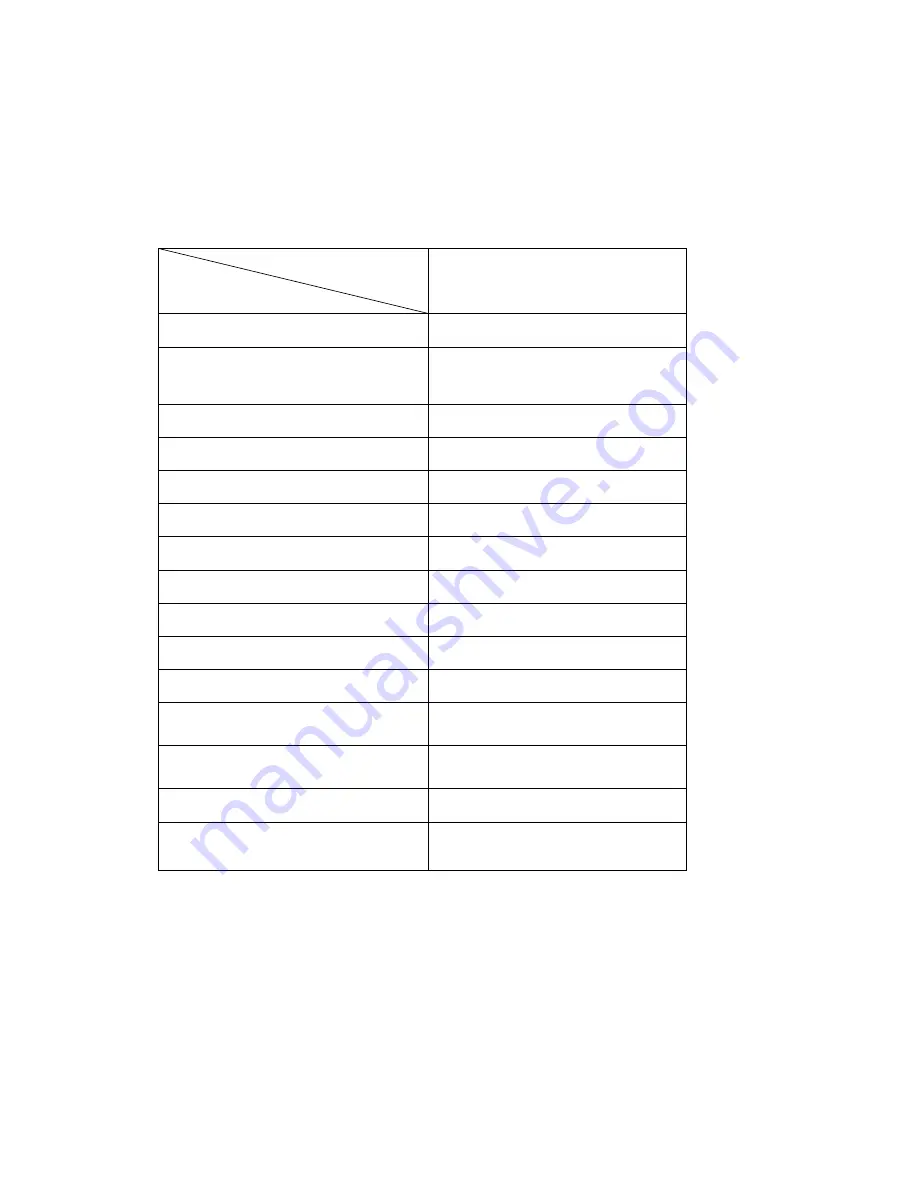

1. Major Technical Parameters

Model

Parameters

LGK-40

Input voltage

(

V

)

AC220V

±

10%

Input power supply capacity

(

KVA

)

6

No-load voltage

(

V

)

230

Current adjustable range

(

A

)

10-40

Rated output voltage

(

V

)

100

Rated duty cycle

(

%

)

60

Efficiency

≥

85

Power factor cosø

0.93

Insulation level

B

Casing protection level

IP21

Arcing mode

contacted

Recommended air compressor

pressure

(

KG

)

4.5

Recommended air compressor

air displacement

(

KG

)

0.17

Net weight

(

kg

)

8

Dimensions

(

mm

)

( L×W×H )

375×155×240

Summary of Contents for LGK-40

Page 11: ......