WINCH MANUAL

IMpORTANT SAFETY INSTRUCTIONS

5

WARNING

Do not operate tool if under the influence of alcohol or drugs.

Read warning labels on prescription to determine if your judgment or

reflexes are impaired while taking drugs. If there is any doubt, do not

operate the tool.

DANGER

Keep hands and body away from Fairlead (cable intake slot) when

operating.

Always secure vehicle in position before using winch.

WARNING

Be certain the winch is properly bolted to a structure (or vehicle) that

can hold the winches maximum rated load.

Do not use inappropriate attachments to extend the length of the

winch cable.

DANGER

Never lift people or hoist loads over people or lift live animals.

Never come in between the winch and the load when operating.

WARNING

Do not apply any loads to the winch when cable is fully extended

past the safety mark. Keep at least 5 full wraps of cable on the spool,

(Usually marked red on the winch cable at the drum end.)

After moving any piece of equipment with the winch, secure the the

equipment in place. Do not rely on the winch to hold for an extended

period of time nor whilst in transport, winches are not securing

device, By doing so will void any warranty

CAUTION

Examine winch before using. Components may be affected by

exposure to chemicals, salts, and rust.

Do not cross over or go underneath winch cable when under load.

Use gloves while handling cable.

WARNING

Never operate winch if cable shows any signs of weakening, such as

knotting or kinking. If it does you must replace immediately.

DANGER

Do not move your vehicle with the cable extended and attached to the

load. You could easily exceed the winch rating and snap the cable.

When the vehicle is parked on an incline you should use wheel chocks.

CAUTION

Always re-spool cable neatly after any operation this will avoid any

winch cable misalignment for the next use

CAUTION

The winch cable must be wound onto the drum under a load of at least

10% of the rated line pull or the outer wraps will draw into inner wraps

and damage winch cable.

Before operating the winch under load you should check proper

function of the winch by engaging and disengaging the clutch, by

operating the directional controls, and operating the speed controls.

This will ensure that the winch is working properly and will help

prevent unintended damage and injury. Cycling the winch prior to

loading will also ensure the gears are properly aligned.

CAUTION

Batteries contain gases which are flammable and explosive. Wear eye

protection during installation and remove all jewelry. Do not lean over

battery while making connections.

WARNING

It is

strongly recommended

a battery isolator is installed to protect

vehicle, equipment and user from hazardous situations, if one isn’t

supplied it is recommended one is purchased and installed before

operation of the winch.

Failure

to install a battery isolator or safety cut off could result in

damage to the vehicle, equipment and(or) operator and will result in

voiding any warranty offered.

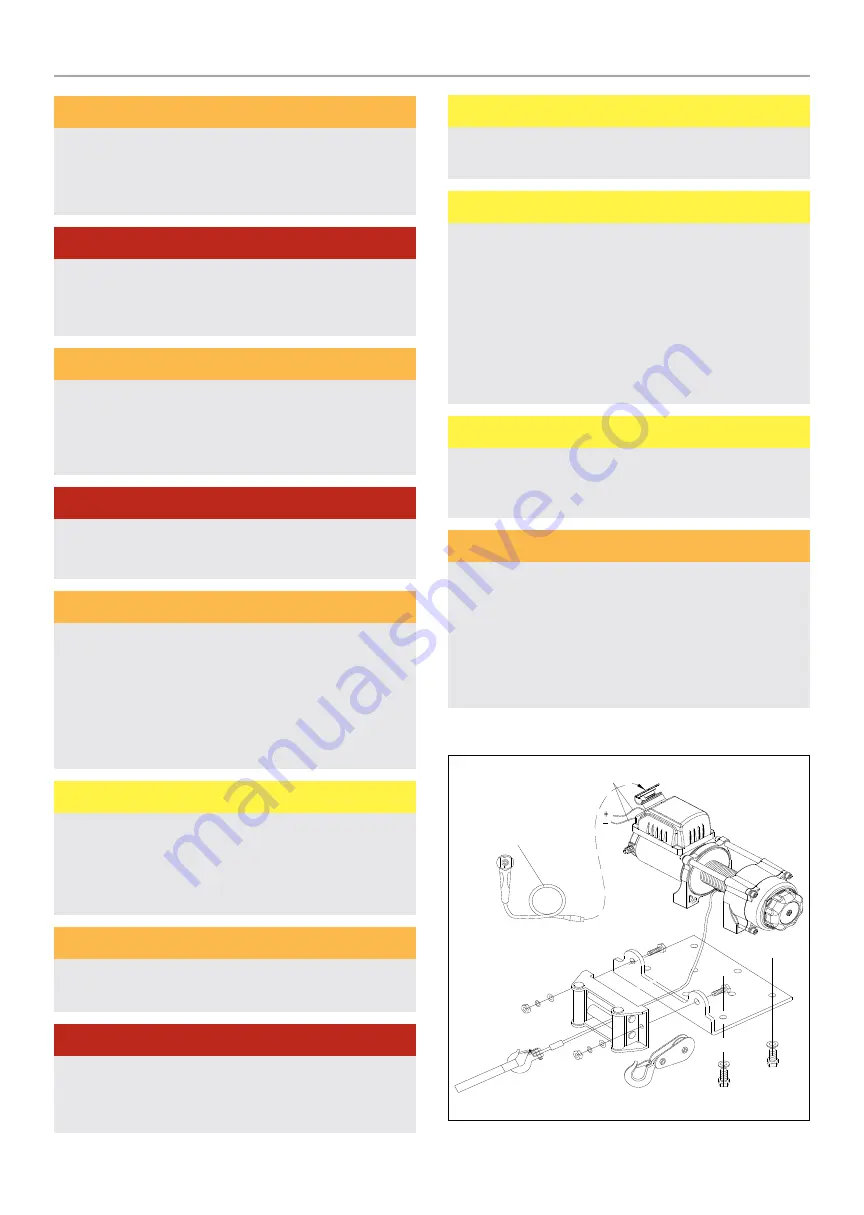

WINCH ASSEMBLY AND MOUNTING

Red B

Black Battery -

Remote Control

1. Your winch is designed with a bolt pattern that is standard in

this class of winch. Many winch mounting kits are available that