WINCH MANUAL

RIGGING TECHNIQUES

6

utilize this bolt pattern for the most popular vehicle and mounting

channels. If you cannot find a kit locally, contact us and we will

provide you with the name of a dealer near you. If you utilize the

mounting channel, you must ensure that it is mounted on a flat

surface so that the three major sections (motor, drum and gear

housing) are properly aligned. Proper alignment of the winch will

allow even distribution of the full rated load and reduce the chance

of damaging winch or equipment. Poor installation contributes to

approx 90% equipment or winch damage.

2. Start by connecting the Roller Fairlead to the Mounting Channel

using 2 each of the Cap Bolt, Flat Washer, Lock Washer and securing

with Nut (Make sure the bolt is placed through the mounting

channel and roller fairlead from inside the channel. This will allow

enough clearance for the winch to be placed in the channel without

obstruction.)

3. Assemble the winch to the (optional) Mounting Channel by first

pulling and releasing the clutch knob to “Out” position (Free

Spooling). Pull out a few inches of cable from the drum and feed the

wire loop through the opening in the front of the mounting channel

and roller fairlead. Now, using the remaining Cap Bolts, Flat Washer,

Lock Washer, and Nut secure the winch to the mounting channel.

4. Connect the battery and motor leads. Remember every type of

winch is different.

CAUTION

Batteries contain gases which are flammable and explosive. Wear eye

protection during installation and remove all jewelry. Do not lean over

battery while making connections.

5. Assemble the Clevis Hook to the cable. Take off the pin from the

Clevis Hook, connect the Clevis Hook to the cable and mount the pin

back to the Clevis Hook.

6. Always use the Hand Saver (Optional) when free-spooling and re-

spooling the wire rope. Using the Hand Saver keeps your hands and

fingers away from the rotating drum.

7. Check for proper drum rotation. Pull or turn the clutch knob to the

“OUT” “Disengage” position (Free-spooling). Pull out some cable

from the drum, and then turn the clutch knob to the “IN” “Engage”

position to engage the gears. Press the cable out button on the

remote lead switch. If the drum is turning and releasing cable, then

your connections are accurate. If the drum is turning and collecting

more cable, then reverse the leads on the motor. Repeat and check

rotation.

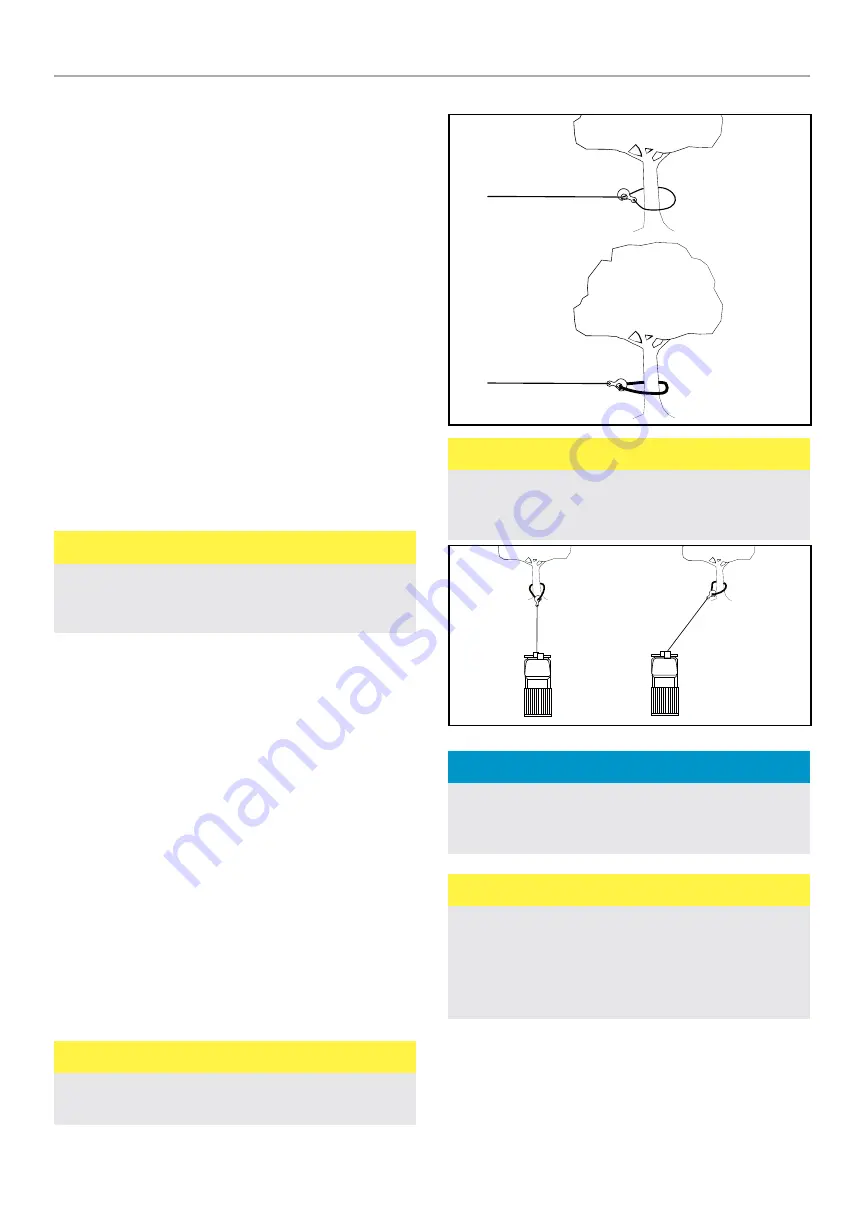

RIGGING TECHNIQUES

Locate a suitable anchor such as a strong tree trunk or boulder.

ALWAYS use a sling or strap as an anchor point on a object, Never use the

cable or hook as a anchor point attached to an object.

CAUTION

NEVER attach the clevis hook back onto the winch cable as this could

cause damage to the cable.

CAUTION

Do not winch from an acute angle as the wire rope will bind up on

one side of the drum causing damage to wire rope (Bird Nesting) and

cause major damage to winch and possible equipment.

NOTICE

Short pulls from an angle can be used to straighten the vehicle/

equipment. Long pulls should be done with the wire rope in a straight

line to winch/vehicle, see above illustration.

CAUTION

When pulling a heavy load, place a blanket or jacket over the wire rope

five or six feet from the hook because in the event of a broken cable it

will dampen the force.

For additional protection open the hood/bonnet of the vehicle as

shown.