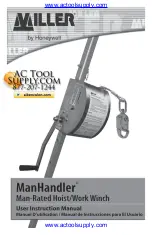

CAUTION

Do not winch from an acute angle as the wire rope

will pile up on one side of the drum causing damage to wire rope

and the winch. Fig 3.2

Short pulls from an angle can be used to straighten the vehicle.

Long pulls should be done with the wire rope at a 90° angle to the

winch/vehicle.

When pulling a heavy load, place a blanket or jacket over the wire

rope five or six feet from the hook. In the event of a broken cable it

will dampen the snap back.

For additional protection open the

hood of the vehicle as shown in Fig 3.3

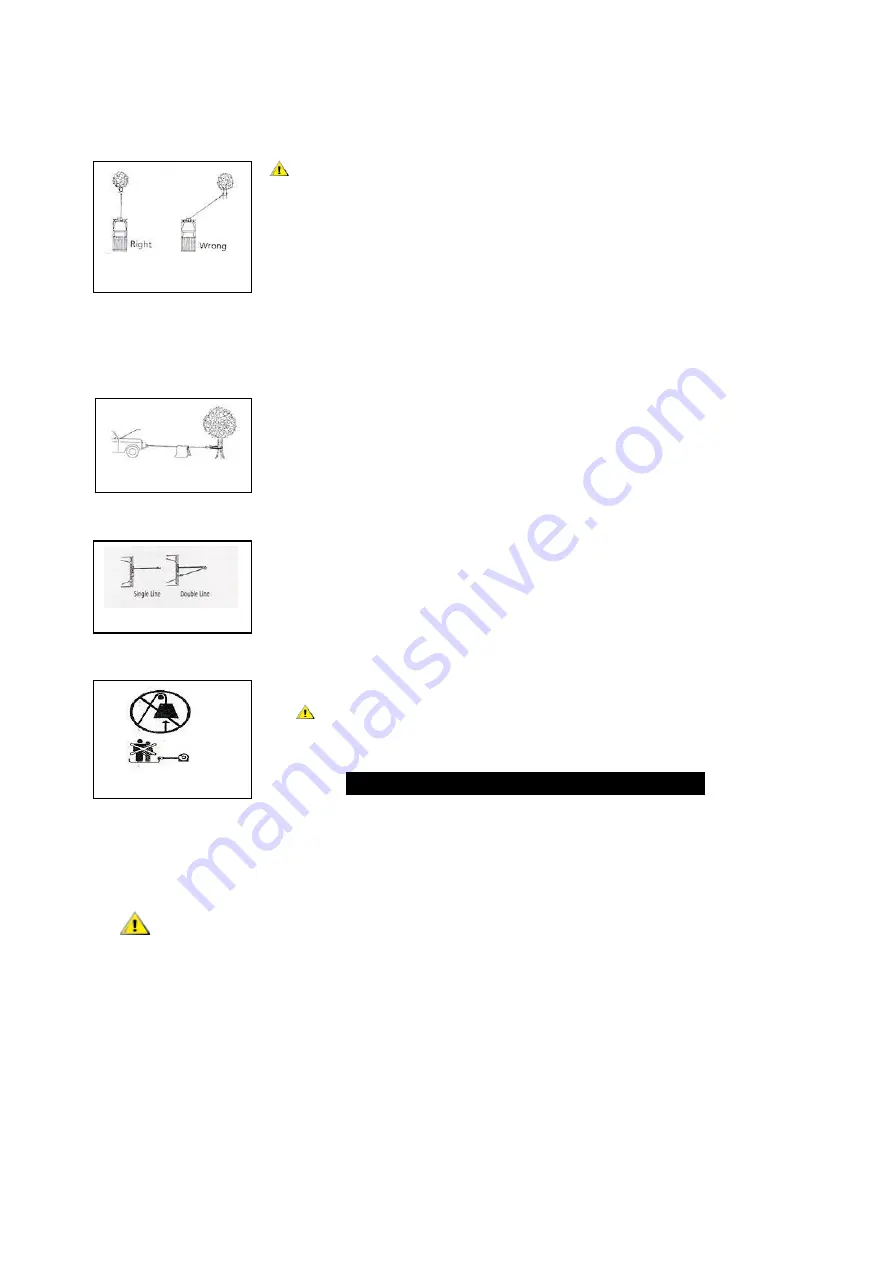

For pulls over 70% rated line pull, we recommend the use of the

snatch block/pulley block to double line the wire rope. Fig 3.4

This reduces the load on the winch and the strain on the rope by up

to 50% depending on the included angle

WARNING -

Never use your winch for overhead hoisting or

for lifting people or moving people.

WINCH WORKING DEMONSTRATION

1.

Disengage the clutch by turning the clutch to the “CLUTCH OUT” position.

2. Grab the cable assembly (Part# 060EN1000) and pull the cable to the desired

length, then attach to item being pulled.

Caution:

Always leave at least five turns of cable on the drum; Review winch

safety warnings and precautions on page 2

、

3 before continuing.

3. Reengage the clutch by turn the clutch assembly (Part# 060EN0700) to the

“CLUTCH IN” position, if the clutch is not engaged, the winch drum must be turned

by hand, until the clutch is totally engaged.

Insert the switch assembly connector onto the control box.

Test-run winch in two directions, each direction for one or two seconds

.

10

4.

5.

Fig 3.5

Fig 3.4

Fig 3.3

Fig 3.2