12

defective rope by free spooling. Remove the bolt (Part# 800009) M8x10 on the

drum and release the rope.

2.

Insert the end of the new rope and secure the M6 x 10 mm bolt tightly.

3.

Engage the clutch and re-spool the new rope on the drum keeping tension on the

rope as it spools. Ensure that the rope is respooling in the under wind position.

WARNING - Only replace the wire rope with the identical replacement

part recommended by the manufacturer.

TROUBLE SHOOTING

SYMPTOM

POSSIBLE CAUSE

SUGGESTED ACTION

Motor does not

turn on

-Switch Assembly not

connected properly

-Loose battery cable

connections

-Defective Switch

Assembly

-Defective motor

-Water has entered motor

-Insert Switch Assembly all the way into

the connector.

-Tighten nuts on all cable connections.

-Replace Switch Assembly.

-Check for voltage at armature port with

Switch pressed. If voltage is present,

replace motor.

-Allow to drain and dry. Run in short

bursts without load until completely dry.

Motor runs but

cable drum does

not turn

-Clutch not engaged

-Turn clutch to the “In” position. If problem

persists, a qualified technician needs to

check and repair.

Motor runs slowly

or without normal

power

-Insufficient current or

voltage

-Battery weak, recharge. Run winch with

vehicle motor running.

-Loose or corroded battery cable

connections. Clean, tighten, or replace.

Motor overheating -Winch running time too

long

-Allow winch to cool down periodically.

Motor runs in one

direction only

-Defective Switch

Assembly

-Loose or corroded battery cable or motor

cable connections. Clean and tighten.

-Repair or replace switch assembly.

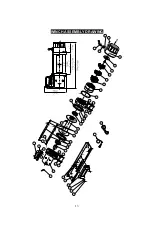

Summary of Contents for 80SPS12

Page 1: ...ELECTRICAL WINCH 80SPS12 80SPS24 Assembly Operating Instructions...

Page 13: ...13 WINCH ASSEMBLY DRAWING OUT IN...

Page 17: ......

Page 18: ......

Page 19: ......