8

not pull for more than one minute at or near the rated load.

CAUTION - If the motor stalls do not maintain power to the

winch. Electric winches are designed and made of intermittent

use and should not be used in constant duty applications.

CAUTION

- Never release the free-spool clutch when there is a load on

the winch.

CAUTION

- Use hand saver hook when handling the hook for spooling

or un-spooling the wire rope.

GENERAL TIPS FOR SAFE OPERATION

x

The 8000lbs and its all derivative types are rated at 8000 lbs

capacity when spooling the first rope layer on the drum. Overloads

can damage the winch/motor/ or wire rope. For loads over 6800 lbs.

we recommend the use of the pulley block/snatch block to double

the wire rope line. The will aid in two ways: a) reduce the number or

rope layers on the drum, as well as, b) reduce the load on the wire

rope by as much as 50%. When doubling the line back to the

vehicle, attach to the frame or other load bearing part.

x

The vehicle engine should be kept running during operation of the

winch to minimize battery drain and maximize power and speed of

the winch. If the winch is used for a considerable time with the

engine off the battery may be drained and too weak to restart the

engine

x

Get to know your winch before you actually need to use it. We

recommend that you set up a few test runs to familiarize yourself

with rigging techniques, the sounds your winch makes under

various loads, the way the cable spools on the drum, etc.

x

Inspect the wire rope and equipment before each use. A frayed or

damaged rope shall be replaced immediately. Use only

manufacturer’s identical replacement rope with the exact

specifications.

x

Inspect the winch installation and bolts to ensure that all bolts are

tight before each operation.

x

Never connect the cable back to itself. This will cause cable

damage. Always use a snatch block, sling or chain of suitable

strength as shown in the illustrations.

x

Store the remote control inside your vehicle in a place that it will not

be damaged.

Summary of Contents for 80SPS12

Page 1: ...ELECTRICAL WINCH 80SPS12 80SPS24 Assembly Operating Instructions...

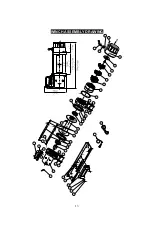

Page 13: ...13 WINCH ASSEMBLY DRAWING OUT IN...

Page 17: ......

Page 18: ......

Page 19: ......