WINCH MANUAL

INTRODUCTION

2

INTRODUCTION

Congratulations on your purchase of a winch. We design and build

winches to strict specifications and with proper use and maintenance your

winch should bring you years of satisfying service.

Every effort has been made to ensure the accuracy and completeness of

the information in this manual at the time of publication, and we reserve

the right to change, alter and/or improve the product and this document

at any time without prior notice.

SAFETY DEFINITIONS

Your winch can develop tremendous pulling forces and if used unsafely

or improperly could result in property damage, serious injury or death.

Throughout this manual, you will find the following symbols for caution,

warning and danger. Pay particular attention to the notes preceded

by these symbols as they are written for your safety. Ultimately, safe

operation of this device rests with you, the operator.

DANGER

DANGER indicates a hazardous situation which,if not avoided, will

result in death or serious injury.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

NOTICE

NOTICE indicates information considered important, but not hazard-

related (e.g., messages relating to property damage).

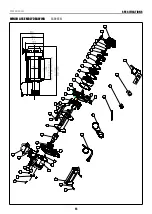

GETTING TO KNOW YOUR WINCH

Your winch is a powerful piece of machinery. It is important that you

understand the basics of its operation and specifications so that

when you need to use it, you can use it with confidence and safety.

Below is a list of the components of your winch and their uses.

1. This winch is engineered for maximum line pull with only one layer of

cable spooled onto the winch drum (the first layer).

2. Motor: The motor is powered by a 12/24-volt battery and provides

power to the gear assembly which turns the drum and winds the wire

rope in a direction.

3. Winch Drum: The winch drum is the cylinder on which the wire rope is

stored. It can be spooled In or Out by use of the remote lead switch.

4. Winch Rope: Your winch been supplied with galvanized aircraft

steel cable or synthetic rope and is designed specifically for load

capacity of the rated line pull of this winch. The cable feeds on from

underneath the drum position, it is looped at one end to accept the

hook.

5. Fairlead (Supplied with selective models): For when using the winch

at an angle the roller fairlead acts to guide the rope onto the drum

evenly and minimizes damage to the rope or winch from abrasion.

6. Gear Assembly System: The reduction gears convert the winch

motor power into extreme pulling forces.

7. Braking System: Braking action is automatically applied to the winch

when the winch motor is stopped or there is a load on the wire rope.

This is achieved by a separate external mechanical brake which

applies the braking action. (Brakes are NOT designed as securing

devices and the winch cables should never be left attached when

vehicle / equipment is in transport).

8. Free Spooling Clutch: The clutch allows the operator to manually

disengage (“CLUTCH OUT”) the spooling drum from the gear train.

This is called free spool. Engaging the clutch (“CLUTCH IN”) locks

the winch into the gear system.

9. Solenoid: Power from the vehicle battery flows through the

weatherproof switch before being directed to the winch motor.

10. Wired Remote lead Switch: The remote switch leads have a dual

switch for powering in or powering out your winch drum. The remote

control allows you to stand clear of the wire rope when the winch is

under load.

11. Wireless remote (Supplied on selective models): This is designed

and offered for ‘Offroad’ or ‘None Commercial’ use only and is not

included in any warranty offered, This allows the operator to always

control the winch from up to 50 Ft away.

12. Universal Flat Bed Mounting Channel: (Optional) Your winch could

have been optionally supplied with a flat bed mounting channel that

can be mounted to most flat surfaces such as trailers, truck beds

and structures etc. The mounting channel also has a number of

mounting holes and holes to accept your roller fairlead.

13. Pulley/Snatch Block: (Optional) If your winch is supplied with a

pulley/snatch block which can double the pulling power of the winch,

or change the pulling direction without damaging the wire rope. We

recommend you to use a double line and snatch block for pulling over

70% of the rated line pull.

Summary of Contents for S2500EN

Page 15: ...Winch Manual SPECIFICATIONS 15 WINCH ASSEMBLY DRAWING 40 39 38 36 41 37 43 42 S4000EN...

Page 18: ...Winch Manual SPECIFICATIONS 18 WINCH ASSEMBLY DRAWING 40 39 38 36 41 37 43 42 S5250...

Page 21: ...Winch Manual SPECIFICATIONS 21 WINCH ASSEMBLY DRAWING 39 38 37 35 40 36 42 41 S6000EN...