4

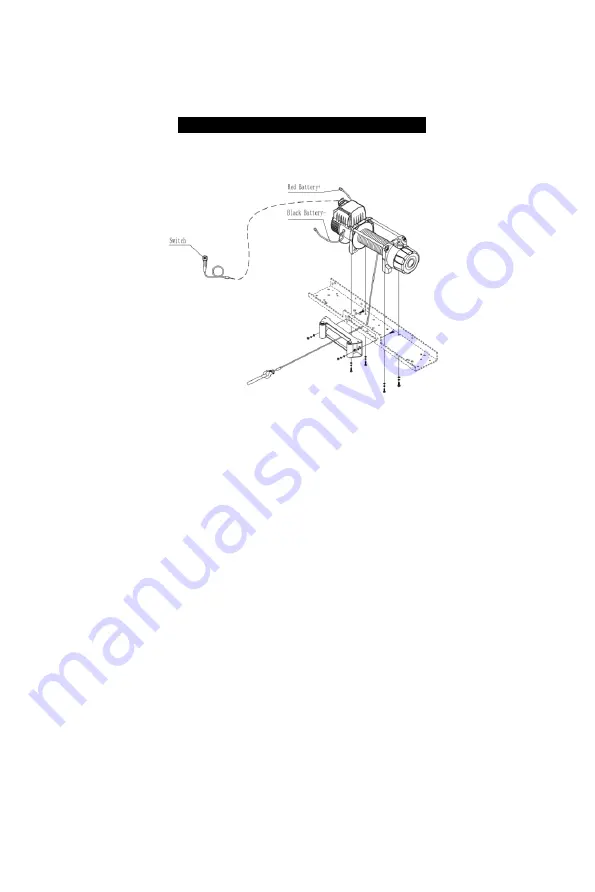

WINCH ASSEMBLY AND MOUNTING

12000lbs:

1. Your 12000lb winch is designed with a bolt pattern that is standard in this class of

winch. Many winch mounting kits are available that utilize this bolt pattern for the

most popular vehicle and mounting channels. If you cannot find a kit locally,

contact us and we will provide you with the name of a dealer near you. If you will

utilize the mounting channel you must ensure that it is mounted on a flat surface

so that the three major sections (motor, drum and gear housing) are properly

aligned. Proper alignment of the winch will allow even distribution of the full rated

load.

2. Start by connecting the Roller Fairlead (Part# 120700) to the Mounting Channel

(Part# 120025) using 2 each of the Cap Bolt M10 X 35 (Part# 120002), Flat Washer

(Part# 120004), Lock Washer (Part# 120003) and securing with M10 Nut(Part#

120024) (Make sure the bolt is placed through the mounting channel and roller

fairlead from inside the channel. This will allow enough clearance for the winch to

be placed in the channel without obstruction.)

3. Assemble the winch to the Mounting Channel (Part# 120025) by first pulling and

releasing the clutch knob to “Off” position (Free Spooling). Pull out a few inches

of cable from the drum and feed the wire loop through the opening in the front of

the mounting channel and roller fairlead. Now, using the remaining M10 x 35 Cap

Summary of Contents for Spartan Series

Page 1: ...ELECTRICAL WINCH 12000 12000 SR Assembly Operating Instructions...

Page 18: ......

Page 19: ......

Page 20: ......