2

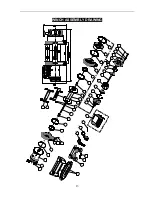

2. Motor: Your motor is powered by a 12/24 volt battery and provides power to the

gear mechanism which turns the drum and winds the wire rope;

3. Winch Drum: The winch drum is the cylinder on which the wire rope is stored. It

can feed or wind the rope depending on the remote winch switch.

4. Wire Rope: Your winch has a

galvanized aircraft cable designed specifically for

load capacity of rated line pull. The wire ro

pe feeds onto the drum in the “under

wind” position through the roller fairlead and is looped at the end to accept the

clevis hook pin.

5. Roller Fairlead: When using the winch at an angle the roller fairlead acts to

guide the wire rope onto the drum and minimizes damage to the wire rope from

abrasion on the winch mount or bumper.

6. Mechanic Gear System: The reduction gears convert the winch motor power

into extreme pulling forces.

7. Braking System: Braking action is automatically applied to the winch drum

when the winch motor is stopped and there is a load on the wire rope. A

separate mechanical brake applies the braking action.

8. Free Spooling Clutch: The clutch allows the operator to manually disengage

(“CLUTCH OUT”) the spooling drum from the gear train, free spool. Engaging

the clutch (“CLUTCH IN”) locks the winch into the gear system.

9. Solenoid: Power from the vehicle battery flows through the weather-sealed

switch before being directed to the winch motor.

10. Remote Switch: The Power switch leads have a dual switch for powering in or

powering out your winch drum. The remote switch allows you to stand clear of

the wire rope when the winch is under load.

11. Wireless Remote Control: allow you control winch far from 50 Ft away.

12. Universal Flat Bed Mounting Channel: Your winch could have been optionally

supplied with a flat bed mounting channel that can be mounted to most flat

surfaces such as trailers, step bumpers, truck beds, etc. The mounting channel

also has holes to accept your roller fairlead.

13. Snatch Block: If your winch is supplied with a snatch block that can double the

pulling power of the winch, or change the pulling direction without damaging the