14

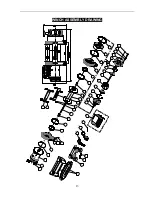

WINCH PARTS LIST

No.

Part #

Qty

Description

Remark

1

80EN0001

12

Lock Washer

Φ8

2

80EN0002

4

Screw M8x 25

3

80EN0100

1

Motor Assembly

4

80EN0003

1

Ring Seals

5

80EN0004

1

Motor Bracket

6

80EN0005

8

Flat Washer

Φ12

7

80EN0006

8

Lock Washer Φ12

8

80EN0007

8

Cap Screw M12 x 30

9

80EN0008

2

Bushing-Drum

10

80EN0009

2

Ring Seals

11

80EN0010

1

Coupling

12

80EN0011

1

Six Angle Bar

13

80EN0012

8

Screw M10 x 25

14

80EN0013

12

Lock Washer

Φ10

15

80EN0014

1

Tie Bar

16

80EN0200

1

Drum Assembly

17

80EN0015

2

Screw M8

×

10

18

80EN0016

1

Coupling

19

80EN0017

1

End Bearing

20

80EN0018

2

Gasket

21

80EN0019

1

Gear

—

Ring

22

80EN0020

1

Circlip For Hole

23

80EN0021

1

Bearing

24

80EN0300

1

Gear Carrier Assembly

(

Output

)

25

80EN0022

1

Circlip For Hole

26

80EN0400

1

Gear Carrier Assembly

(

Intermediate

)

27

80EN0500

1

Brake/ Shaft Assembly

28

80EN0023

1

Gear

—

Input Sun

29

80EN0024

3

Planetary Gear

30

80EN0025

1

Trust Washer

31

80EN0026

1

Bearing

32

80EN0600

1

Clutch Assembly

33

80EN0027

1

Gear

—

Housing

34

80EN0028

8

Flat Washer

Φ8

35

80EN0029

8

Screw M8x 90

36

80EN0030

1

Tie Bar(I)

37

80ENS0031

1

Roller Fairlead

80ENS24

80ENA0031

1

Aluminium Fairlead

80ENA24

38

80EN0700

1

Tensioned Of Steel Wire Supplied Assembly

80ENS24

39

80EN0032

4

Screw M10 x 20

80ENS24

40

80EN0033

1

Switch

41

80ENS0800

1

Cable Assembly

80ENS24

80ENA0800

1

Cable Assembly

80ENA24

42

80EN0034

1

Strap

43

80EN0900

1

Control Section

44

80EN0035

4

Heel Block