10

A

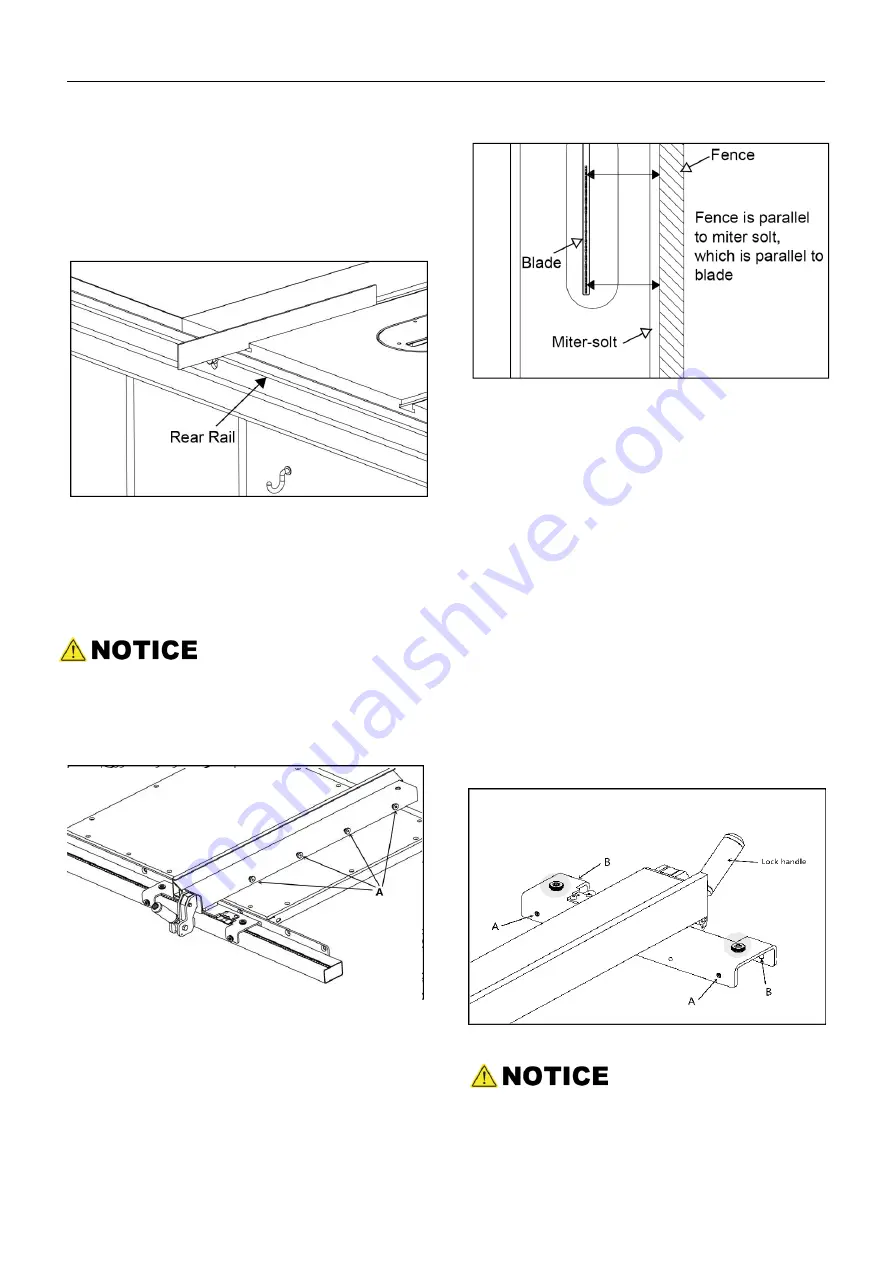

3.4.4 Install the rail & extension table

1.

Install the rail and extension table as breakdown

shows.

Before tightening the rear rail, check to make sure

the

top

edge

of

the

rear

rail

is

lower

than

the

T-slot

,

as shown in Fig. 9.

Ensure that the extension table is coplanar with the

main table.

Fig. 9

2.

Install the fence on the rail on the right hand side

of the blade as shown in

Fig. 10

.

If you need to use the fence on the left side of

the blade, remove the knobs (A), as shown in

Fig.10, and move the fence plate and locking

bar to the right side of the fence body, secure

them on the left side of the fence body.

Fig. 10

3.

Check

the

fence

parallelism

and

perpendicularity

(

Fig.11

)

As shown in Fig.11, after securing the fence,

ensure that the fence is parallel to the miter slot,

which is parallel to blade at any locations. And

make sure that the distance L

1

>L

2

, L

1

-L

2

<1/64",

which creates a slightly larger opening between the

fence and the blade, at the rear of the blade, to

reduce the risk of workpiece binding or burning as

it is fed through the cut.

Fig. 11

4.

Adjust the parallelism and perpendicularity of

the fence (

Fig.12

)

If the fence or blade is not parallel to the T-slot, or

the fence is not perpendicular to the table, you can

adjust as following content:

a. Align the the parallelism between the blade

and T-slot.

Before aligning perpendicularity or parallelism of

the fence, you must align the parallelism between

the blade and T-slot, refer to chapter

6.2 Aligning

the Table T-slot Parallel with the Blade.

b. Align the the parallelism between the fence

and T-slot or blade.

By adjusting the set screw (A), you can adjust the

parallelism between fence and blade, also you can

adjust the locking strength. By adjusting the bolt

marked in a circle as shown in Fig. 12, you can

adjust the the perpendicularity between the fence

and table. By adjusting the set screw (B), you can

adjust the sliding smoothness of the fence.

Fig. 12

By adjusting the support screw (not shown) at

the underneath of the fence, you can raise or

lower the fence to ensure that the underneath

of the fence is parallel to the table.

L

1

L

2