12

3.4.8 Install the blade guard

1.

Remove the table insert;

2.

Unlockthe handle.

Fig. 16

3.4.9 Extraction system

A dust collection device should be used by the

customer

,

the

dust

extraction

equipment

must

be switched on before commencing machining.

1. Installation of the Dust Outlet

(Fig.18

)

The dust outlet is pre-connected with the flex pipe

and placed in the cabinet. Disconnect the flex pipe

with the dust outlet and pass the pipe through the

cabinet. Then reconnect the flex pipe with the dust

outlet and secure the dust outlet on the cabinet.

Note:

The mounting hardware of the dust outlet is

pre-mounted on the cabinet.

Fig. 16

3.

Slide the blade guard spreader all the way down

into the block, then lock the handle.

Fig. 16

4.

Slide the blade guard onto the spreader, tighten

the lock knob.

Fig. 17

Fig. 17

5.

Re-lock the handle.

Check if the saw blade is tightened before

operating the machine.

Give the spreader an upward tug to verify if it is

locked in place.

Fig. 18

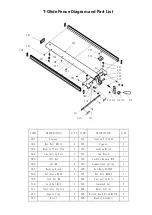

2.

Installation of the over arm

(Fig.19)

:

a.

Fit the bracket (A) to the rear rail with screw (B).

b.

Fit the over arm to the bracket (A) with clip (C).

(Total 2 sets of clasps)

c.

Connect the pipe (1.5”) provided by us to the

dust outlet as

Fig. 22

shows..

Note

:

All

the

hardware

here

is

pre-mounted

on

the

over arm assembly.

Fig. 19

Requirements for the dust collector:

1.

Required air flow: 470 CFM (800 m³/h).

2.

Ensure pressure drop of each dust collector

outlet carrying air current speed: 1100Pa

3.

Dry chips: 3937 FPM (20 m/s).

4.

Wet chips: 5511 FPM (28 m/s). (water content

is equal to 18%)