17

5. Operations

5.1 Electrical Operation

Two types of the switches are alternative for

your machine, the actual object shall prevail.

Refer to

Fig. 28 & Fig.29

“ON” Button:

Start the machine.

“OFF” Button:

Stop the machine.

Hole for Safety Lock:

While not using the

machine, insert the safety pin to prevent

accidental start up.

Fig. 29

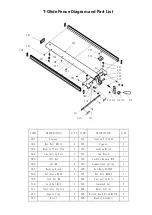

5.2 Blade Elevation and Tilting Adjustment

To adjust the blade elevation :

Loosen the lock

knob (C) as shown in

Fig. 30

and turn the elevation

hand wheel (D). When the desired height is

obtained, re-tighten the knob (C). The blade should

be raised 1/8” to 1/4” above the top surface of the

material being cut.

To adjust the blade tilting :

L

oosen the lock

knob (B) and turn the hand wheel (A). When the

desired angle is obtained, re-tighten the knob (B).

Refer to

Fig. 30.

Fig. 30

6. Maintenance

This table saw has TEFC motor and sealed

lubricated bearings, which requires very little

maintenance other than minor lubrication and

cleaning. Please do the maintenance as following

contents.

LUBRICATION

Clean off the wood chips on the worm gears and

trunnions and apply the grease to keep them

lubricated.

Lubricate once a month.

CLEANING

Clean the wood chips on the table surface and in

the cabinet.

Clean once a day.

CHANGING BELT

Make sure the power cord is disconnected from

the power source!

1.

Lower the blade completely, then open the

motor cover (right side), remove the repair panel

(left side), refer to

Fig. 31.

2.

Loosen the hex bolt that secures the motor and

raise the motor fully to remove tension on the V-

Ribbed belt. Roll the V-Ribbed belt off.

3.

Raise the motor and install a new V-Ribbed belt

onto the pulleys, lower the motor to tension the V-

Ribbed belt, then tighten the cap screws.

4.

Close the motor cover and repair panel.

Fig. 31