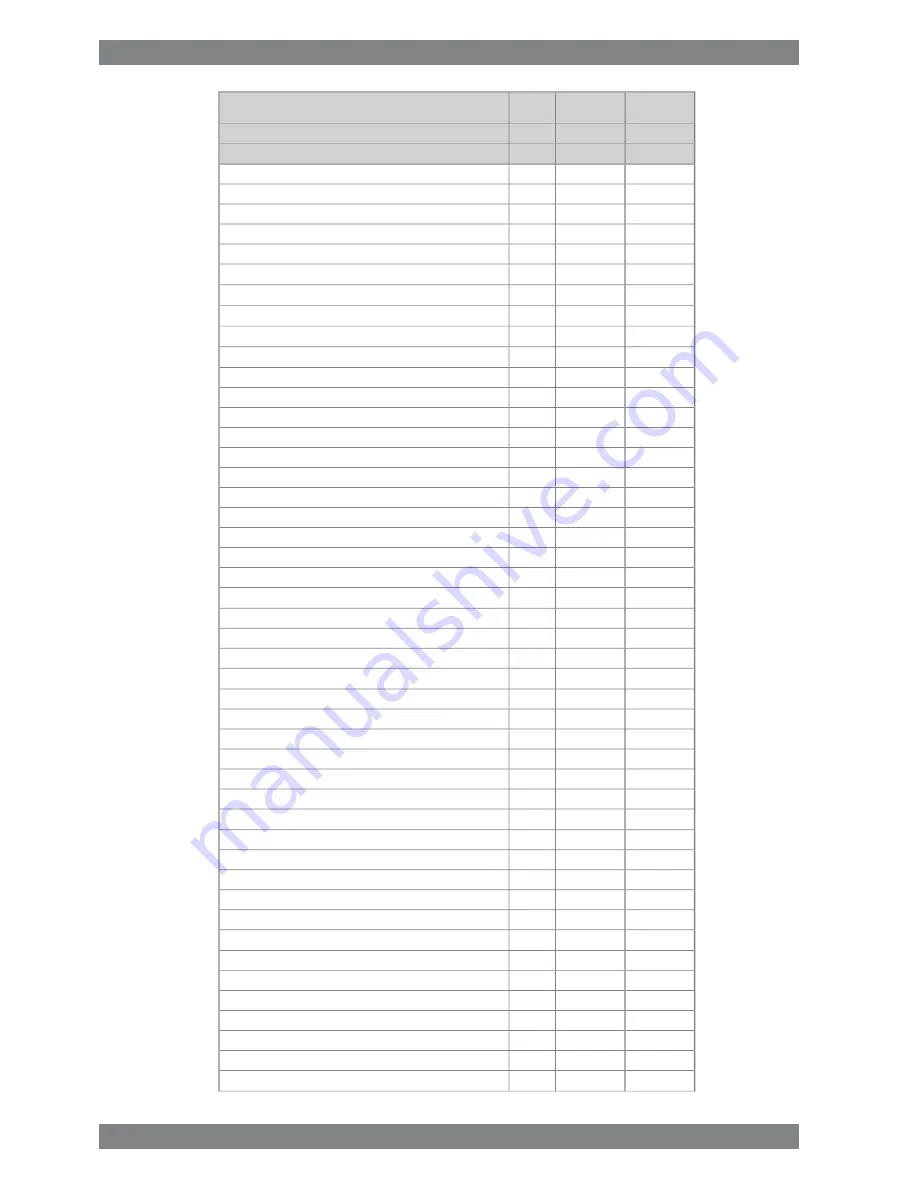

DE

IMO Tier 2

ME

IMO Tier 2

Wärtsilä 14V46F

1200

1200

kW

Cylinder output

600

600

rpm

Engine speed

800

800

kPa

Pressure after pump, max.

40

40

kPa

Suction ability main pump, including pipe loss, max.

80

80

kPa

Priming pressure, nom. (PT 201)

56

56

°C

Temperature before bearings, nom. (TE 201)

75

75

°C

Temperature after engine, approx.

306

335

m

3

/h

Pump capacity (main), engine driven

250

297

m

3

/h

Pump capacity (main), electrically driven

230

230

m

3

/h

Oil flow through engine

80

80

m

3

/h

Priming pump capacity

26.3

26.3

m

3

Oil tank volume in separate system, min

0.7

0.7

g/kWh

Oil consumption at 100% load, approx.

4180

4180

l/min

Crankcase ventilation flow rate at full load

0.4

0.4

kPa

Crankcase ventilation backpressure, max.

70.0

70.0

l

Oil volume in turning device

7.1

7.1

l

Oil volume in speed governor

High temperature cooling water system

250 + static

250 + static

kPa

Pressure at engine, after pump, nom. (PT 401)

530

530

kPa

Pressure at engine, after pump, max. (PT 401)

74

74

°C

Temperature before cylinders, approx. (TE 401)

91...95

91...95

°C

Temperature after charge air cooler, nom.

240

240

m

3

/h

Capacity of engine driven pump, nom.

150

150

kPa

Pressure drop over engine, total

100

100

kPa

Pressure drop in external system, max.

70...150

70...150

kPa

Pressure from expansion tank

2.3

2.3

m

3

Water volume in engine

Low temperature cooling water system

250 + static

250 + static

kPa

Pressure at engine, after pump, nom. (PT 451)

530

530

kPa

Pressure at engine, after pump, max. (PT 451)

38

38

°C

Temperature before engine, max. (TE 451)

25

25

°C

Temperature before engine, min. (TE 451)

240

240

m

3

/h

Capacity of engine driven pump, nom.

50

50

kPa

Pressure drop over charge air cooler

20

20

kPa

Pressure drop over built-on lube oil cooler

30

30

kPa

Pressure drop over built-on temp. control valve

150

150

kPa

Pressure drop in external system, max.

70 ... 150

70 ... 150

kPa

Pressure from expansion tank

0.7

0.7

m

3

Water volume in engine

Starting air system (Note 5)

3000

3000

kPa

Pressure, nom. (PT 301)

1500

1500

kPa

Pressure at engine during start, min. (20°C)

3000

3000

kPa

Pressure, max. (PT 301)

1800

1800

kPa

Low pressure limit in air vessels

14.0

14.0

Nm

3

Consumption per start at 20°C (successful start)

3-18

Wärtsilä 46F Product Guide - a19 - 1 December 2017

Wärtsilä 46F Product Guide

3. Technical Data

Summary of Contents for 12V46F

Page 1: ...PRODUCT GUIDE Wärtsilä 46F ...

Page 44: ...This page intentionally left blank ...

Page 52: ...This page intentionally left blank ...

Page 78: ...This page intentionally left blank ...

Page 102: ...This page intentionally left blank ...

Page 124: ...This page intentionally left blank ...

Page 144: ...This page intentionally left blank ...

Page 162: ...This page intentionally left blank ...

Page 186: ...This page intentionally left blank ...

Page 192: ...This page intentionally left blank ...

Page 194: ...This page intentionally left blank ...

Page 197: ......

Page 198: ......

Page 199: ......