Page | 100

14.

Automation System

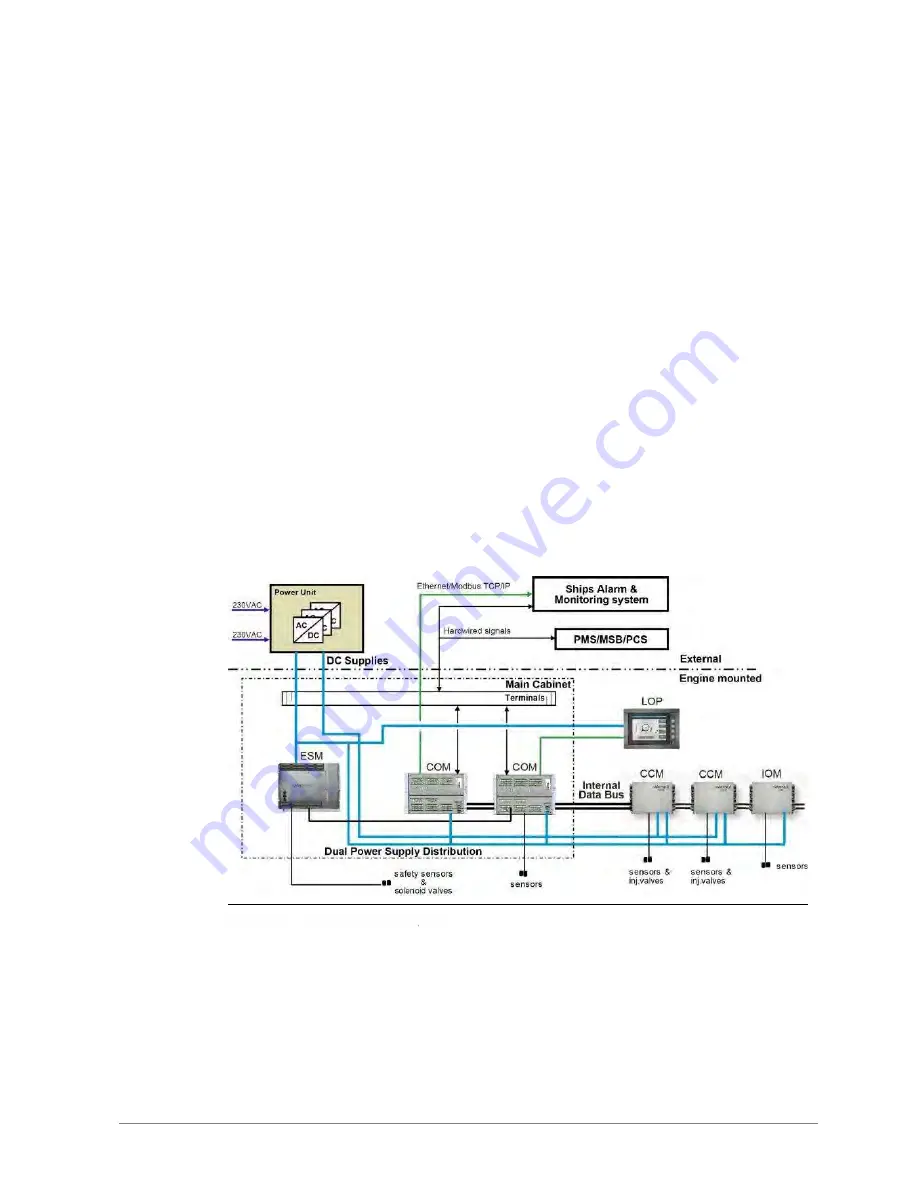

Wärtsilä Unified Controls - UNIC is a fully embedded and distributed engine management system,

which handles all control functions on the engine; for example start sequencing, start blocking,

fuel injection, ignition control, cylinder balancing, knock control, speed control, load sharing,

normal stops and safety shutdowns.

The distributed modules communicate over an internal communication bus.

The power supply to each module is physically doubled on the engine for full redundancy.

Control signals to/from external systems are hardwired to the terminals in the main cabinet on the

engine. Process data for alarm and monitoring are communicated over a Modbus TCP connection

to external systems.

14.1

Technical data and system overview

14.1.1 Ingress protection

The ingress protection class of the system is IP54 if not otherwise mentioned for specific

modules.

14.1.2 Ambient temp for automation system

The system design and implementation of the engine allows for an ambient engine room

temperature of 55°C.

Single components such as electronic modules have a temperature rating not less than 70°C.

Short explanation of the modules used in the system:

COM

Communication Module. Handles strategic control functions (such as start/stop

sequencing and speed/load control, i.e. "speed governing") of the engine.

The communication modules handle engine internal and external communication, as well as

hardwired external interfaces.

LOP

The LOP (local operator panel) shows all engine measurements (e.g. temperatures and

pressures), provides various engine status indications as well as an event history and local

control.

A

Summary of Contents for 31SG

Page 1: ...Page 1 PRODUCT GUIDE W rtsil 31SG...

Page 4: ...Page 4 This page intentionally left blank...

Page 8: ...Page 8 This page intentionally left blank...

Page 14: ...Page 14 This page intentionally left blank...

Page 21: ...Page 21 This page intentionally left blank...

Page 43: ...Page 43 This page intentionally left blank...

Page 49: ...Page 49 Fig 5 1 Flexible hoses...

Page 52: ...Page 52 This page intentionally left blank...

Page 58: ...Page 58 Fig 6 4 Gas valve unit reference P I diagram DAAF051037D...

Page 60: ...Page 60 Fig 6 7 Gas valve unit P I diagram open type DAAF085795A...

Page 64: ...Page 64 Fig 7 2 Lubricating oil system single engine wet sump DAAF301501B...

Page 65: ...Page 65 Fig 7 3 Lubricating oil system Gas multiple engines wet sump DAAF301500A...

Page 72: ...Page 72 This page intentionally left blank...

Page 77: ...Page 77 Fig 9 1 Example diagram for multiple main engines DAAF301505A...

Page 87: ...Page 87 This page intentionally left blank...

Page 98: ...Page 98...

Page 109: ...Page 109 This page intentionally left blank...

Page 113: ...Page 113 This page intentionally left blank...

Page 119: ...Page 119 This page intentionally left blank...

Page 122: ...Page 122 18 4 1 Service space requirement 18 4 1 1 Service space requirement engine...

Page 124: ...Page 124 This page intentionally left blank...

Page 127: ...Page 127 This page intentionally left blank...

Page 129: ...Page 129 This page intentionally left blank...

Page 132: ...W rtsil 31SG Product Guide Page 132 21 2 Collection of drawing symbols used in drawings...