●

Feed pump (1P02)

●

Pre-heater (1E01)

●

Sludge tank (1T05)

●

Separator (1S01/1S02)

●

Sludge pump

●

Control cabinets including motor starters and monitoring

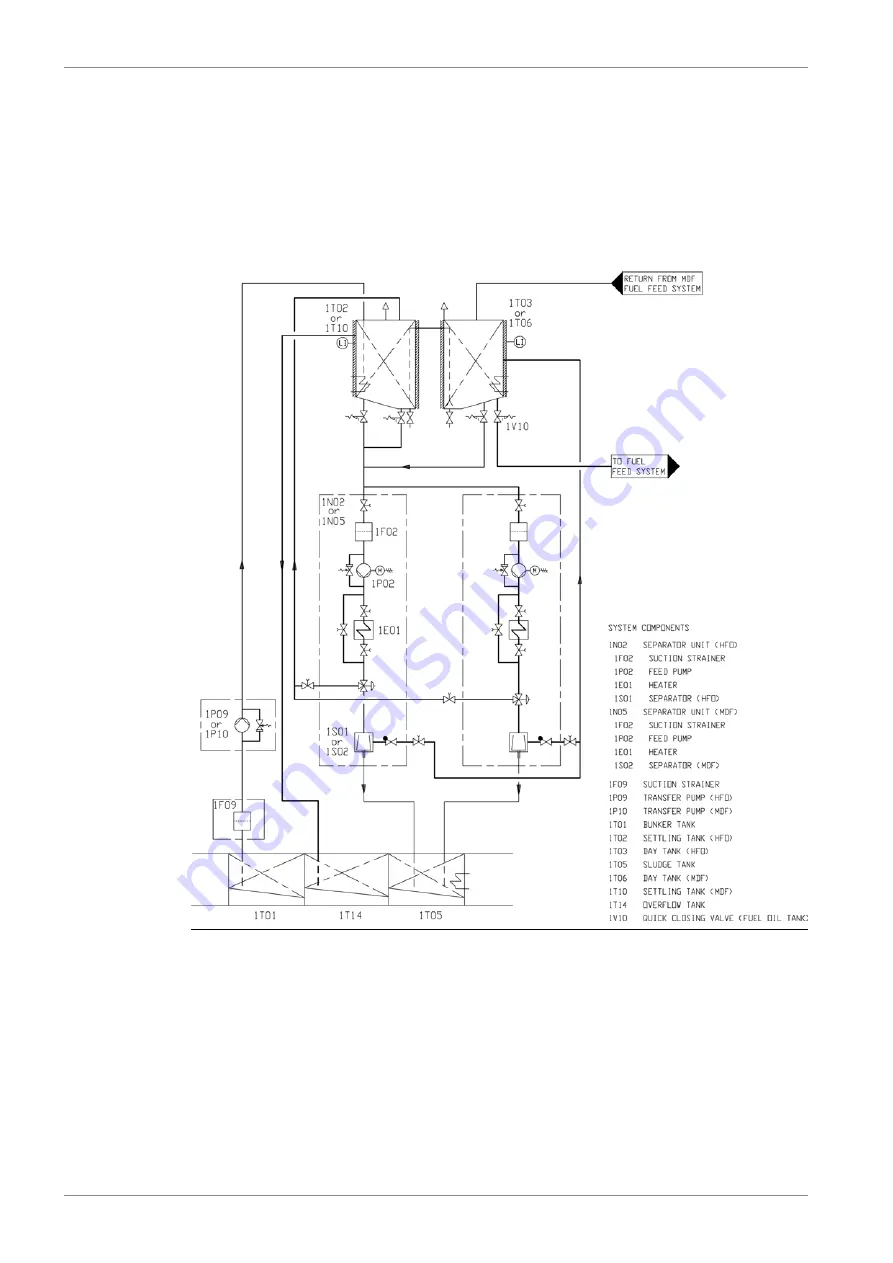

Fig 6-13

Fuel transfer and separating system (V76F6626G)

Separator feed pumps (1P02)

Feed pumps should be dimensioned for the actual fuel quality and recommended throughput

of the separator. The pump should be protected by a suction strainer (mesh size about 0.5

mm)

An approved system for control of the fuel feed rate to the separator is required.

MDF

HFO

Design data:

0.5 MPa (5 bar)

0.5 MPa (5 bar)

Design pressure

6-30

DBAD209883

Wärtsilä 46DF Product Guide

6. Fuel System

Summary of Contents for 46DF

Page 1: ...W rtsil 46DF PRODUCT GUIDE...

Page 4: ...This page intentionally left blank...

Page 8: ...This page intentionally left blank...

Page 16: ...This page intentionally left blank...

Page 118: ...This page intentionally left blank...

Page 140: ...This page intentionally left blank...

Page 148: ...This page intentionally left blank...

Page 174: ...This page intentionally left blank...

Page 186: ...This page intentionally left blank...

Page 198: ...This page intentionally left blank...

Page 206: ...This page intentionally left blank...

Page 214: ...This page intentionally left blank...

Page 218: ...This page intentionally left blank...

Page 230: ...This page intentionally left blank...

Page 234: ...This page intentionally left blank...

Page 236: ...This page intentionally left blank...

Page 241: ...Fig 21 7 List of symbols DAAF406507 7 DBAD209883 21 5 21 ANNEX W rtsil 46DF Product Guide...