6.3

Fuel gas system

6.3.1

Internal fuel gas system

On the engine, the gas is supplied through common main gas pipes, double wall, running

along the engine, continuing with individual feed pipes to each main gas admission valve

located on the cylinder head. At the gas outlet end there is a gas vent system including the

MCC de-gassing valve (formerly called “venting valve”) which releases the gas pressure.

The gas pressure is controlled on the external Gas Valve Unit (GVU), by the engine control

system based on the engine load. The gas goes through the gas manifold which feeds the

main Gas Admission Valves. The gas is mixed with the intake air immediately upstream of the

inlet valve in the cylinder head. Combustion is initiated by a small amount of pilot fuel oil

injected into the cylinder (pilot fuel), through the smaller nozzle of the injection valve.

A safety filter is placed before every gas admission valve, preventing particles from entering

the valve, with a filtration degree of 80 microns nominal.

Double-wall pipes are used. The gas flows to the cylinders through inner pipes, and the annular

space between the walls is ventilated.

Venting of internal of gas pipes let residual gas fuel dissipate at engine stop, at tripping from

gas to diesel, and in some other situations. The on-engine MCC De-gassing valve releases

the gas pressure from the on-engine pipe and from the external branch between engine and

external GVU gas pressure control valve, to a safe external place. Its other function occurs at

gas mode activation: it shortly opens to let the gas fill the gas pipes.

Ventilation of annular space between the walls is made artificially by underpressure with

flushing air. External ventilation fans installed close to GVU unit brings directly any gas leakage

occurred into the annular space to the gas detectors. Gas detectors sense abnormal presence

of gas particles leaked in the intermediate wall of the pipe, and are installed close to the

external ventilation fans, one per each GVU.

Gas detectors sense abnormal presence of gas particles leaked in the intermediate wall of

the pipe, and are installed close to the external ventilation fans, one per each GVU.

Gas detectors have to be installed in engine room, above engine, to detect gas leakage, due

to a classification societies requirement.

Gas detectors sense abnormal presence of gas particles leaked in the intermediate wall of

the pipe, and are installed close to the external ventilation fans, one per each GVU.

Gas detectors have to be installed in engine room, above engine, to detect gas leakage, due

to a classification societies requirement.

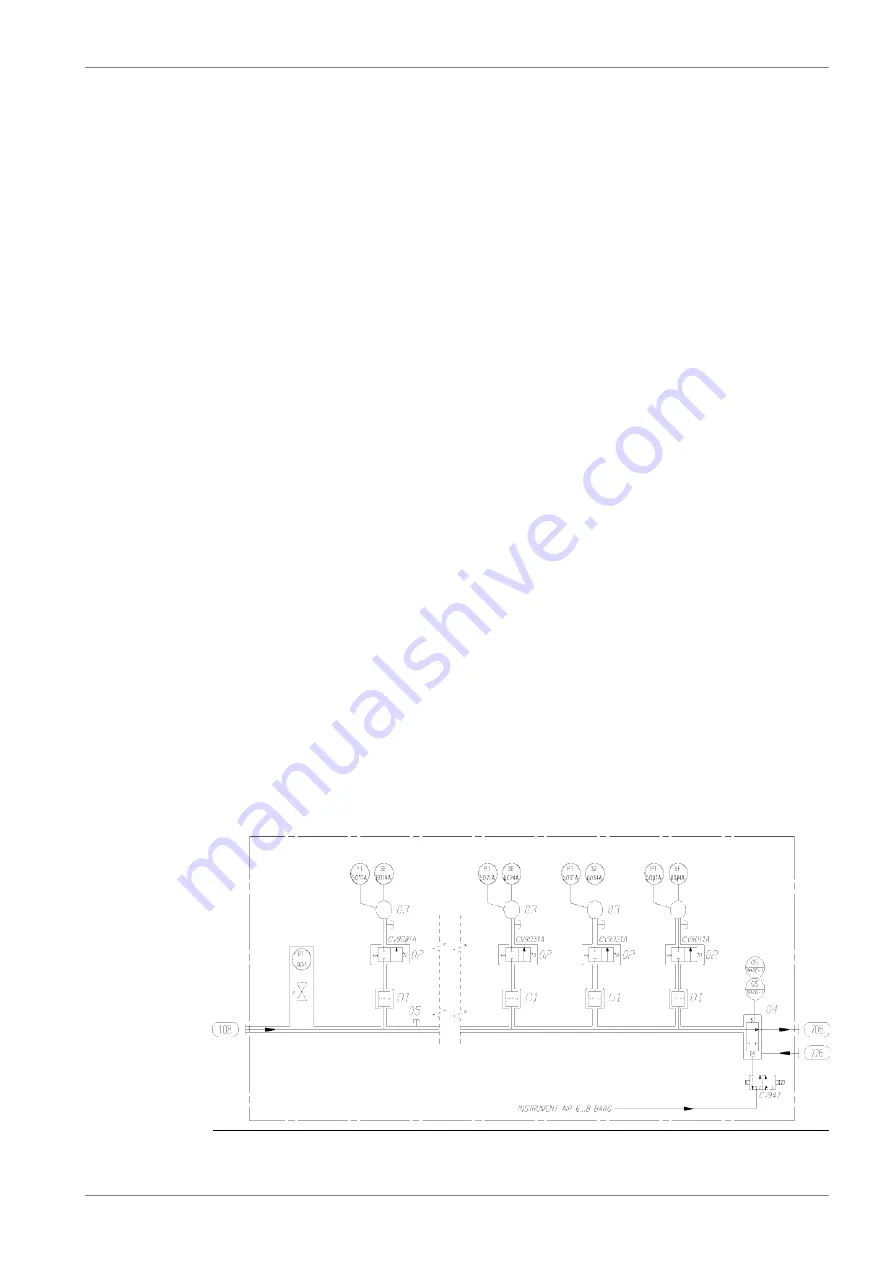

Fig 6-2

Internal fuel gas system, in-line engines (DAAF447413)

DBAD209883

6-11

6. Fuel System

Wärtsilä 46DF Product Guide

Summary of Contents for 46DF

Page 1: ...W rtsil 46DF PRODUCT GUIDE...

Page 4: ...This page intentionally left blank...

Page 8: ...This page intentionally left blank...

Page 16: ...This page intentionally left blank...

Page 118: ...This page intentionally left blank...

Page 140: ...This page intentionally left blank...

Page 148: ...This page intentionally left blank...

Page 174: ...This page intentionally left blank...

Page 186: ...This page intentionally left blank...

Page 198: ...This page intentionally left blank...

Page 206: ...This page intentionally left blank...

Page 214: ...This page intentionally left blank...

Page 218: ...This page intentionally left blank...

Page 230: ...This page intentionally left blank...

Page 234: ...This page intentionally left blank...

Page 236: ...This page intentionally left blank...

Page 241: ...Fig 21 7 List of symbols DAAF406507 7 DBAD209883 21 5 21 ANNEX W rtsil 46DF Product Guide...