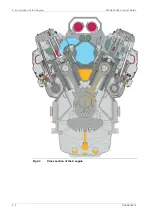

All crankshafts can be equipped with a torsional vibration damper at the free end of the engine,

if required by the application. Full output is available also from the free end of the engine

through a power-take-off (PTO).

The main bearing and crankpin bearing temperatures are continuously monitored.

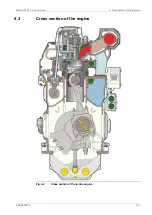

4.2.3

Connecting rod

The connecting rods are of three-piece design, which makes it possible to pull a piston without

opening the big end bearing. Extensive research and development has been made to develop

a connecting rod in which the combustion forces are distributed to a maximum area of the

big end bearing.

The connecting rod of alloy steel is forged and has a fully machined shank. The lower end is

split horizontally to allow removal of piston and connecting rod through the cylinder liner. All

connecting rod bolts are hydraulically tightened. The gudgeon pin bearing is made of solid

aluminium bronze.

Oil is led to the gudgeon pin bearing and piston through a bore in the connecting rod.

4.2.4

Main bearings and big end bearings

The main bearings and the big end bearings have steel backs and thin layers for good resistance

against fatigue and corrosion. Both tri-metal and bi-metal bearings are used.

4.2.5

Cylinder liner

The centrifugally cast cylinder liner has a high and rigid collar preventing deformations due to

the cylinder pressure and pretension forces. A distortion-free liner bore in combination with

wear resistant materials and good lubrication provide optimum running conditions for the

piston and piston rings. The liner material is a special grey cast iron alloy developed for excellent

wear resistance and high strength.

Accurate temperature control is achieved with precisely positioned longitudinal cooling water

bores.

An anti-polishing ring removes deposits from piston top land, which eliminates increased

lubricating oil consumption due to bore polishing and liner wear.

4.2.6

Piston

The piston is of two-piece design with nodular cast iron skirt and steel crown. Wärtsilä patented

skirt lubrication minimizes frictional losses and ensure appropriate lubrication of both the

piston skirt and piston rings under all operating conditions.

4.2.7

Piston rings

The piston ring set consists of two compression rings and one spring-loaded conformable oil

scraper ring. All piston rings have a wear resistant coating.Two compression rings and one

oil scraper ring in combination with pressure lubricated piston skirt give low friction and high

seizure resistance. Both compression ring grooves are hardened for good wear resistance.

4.2.8

Cylinder head

A rigid box/cone-like design ensures even circumferential contact pressure and permits high

cylinder pressure. Only four hydraulically tightened cylinder head studs simplify the maintenance

and leaves more room for optimisation of the inlet and outlet port flow characteristics.

The exhaust valve seats are water cooled. Closed seat rings without water pocket between

the seat and the cylinder head ensure long lifetime for valves and seats. Both inlet and exhaust

valves are equipped with valve rotators.

4-2

DAAB605814

Wärtsilä 46F Product Guide

4. Description of the Engine

Summary of Contents for 46F Series

Page 1: ...Wärtsilä 46F PRODUCT GUIDE ...

Page 4: ...This page intentionally left blank ...

Page 8: ...This page intentionally left blank ...

Page 18: ...This page intentionally left blank ...

Page 86: ...This page intentionally left blank ...

Page 104: ...This page intentionally left blank ...

Page 154: ...This page intentionally left blank ...

Page 162: ...This page intentionally left blank ...

Page 170: ...This page intentionally left blank ...

Page 176: ...This page intentionally left blank ...

Page 194: ...This page intentionally left blank ...

Page 200: ...This page intentionally left blank ...

Page 202: ...This page intentionally left blank ...

Page 207: ...Fig 21 7 List of symbols DAAF406507 7 DAAB605814 21 5 21 ANNEX Wärtsilä 46F Product Guide ...