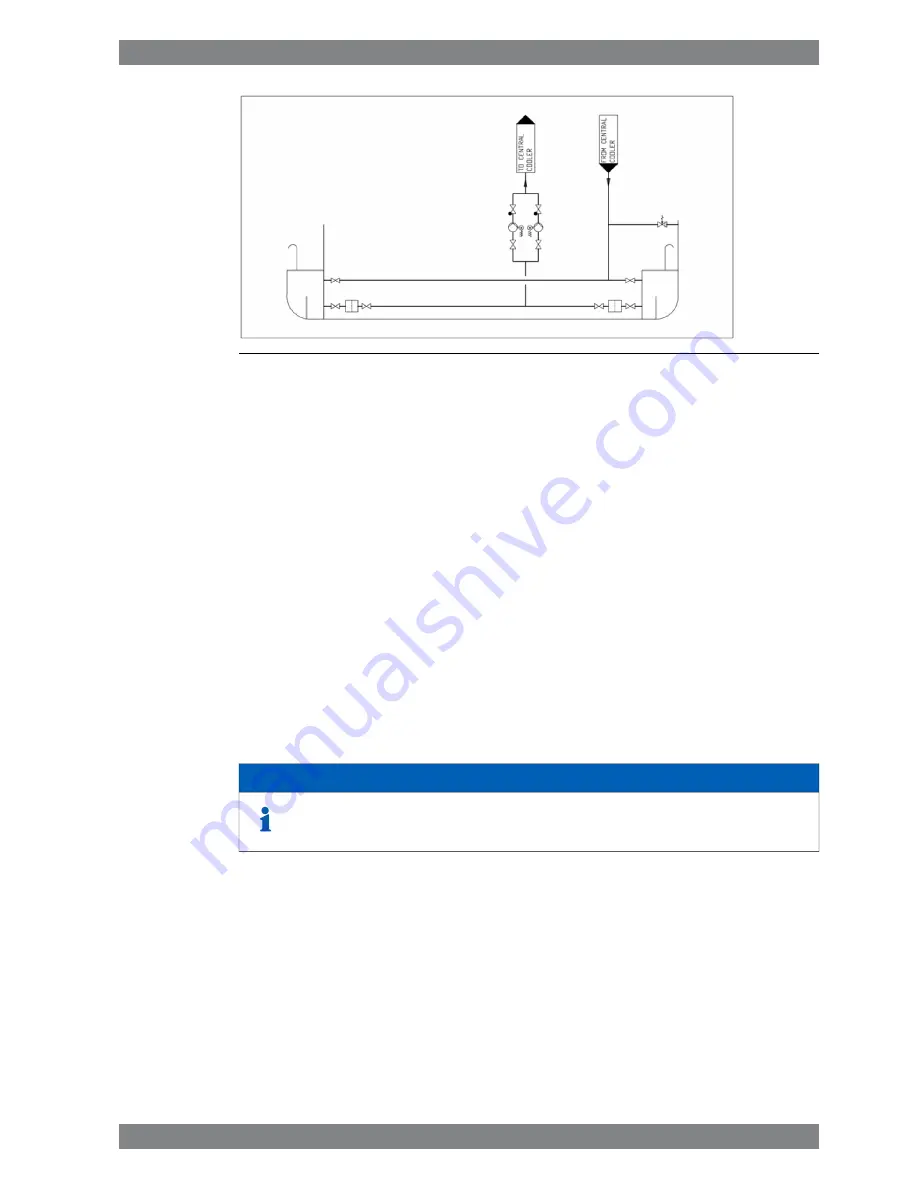

Fig 9-11

Example flow diagram of arctic sea water system

It is recommended to divide the engines into several circuits in multi-engine installations. One

reason is of course redundancy, but it is also easier to tune the individual flows in a smaller

system. Malfunction due to entrained gases, or loss of cooling water in case of large leaks

can also be limited. In some installations it can be desirable to separate the HT circuit from

the LT circuit with a heat exchanger.

The external system shall be designed so that flows, pressures and temperatures are close

to the nominal values in Technical data and the cooling water is properly de-aerated.

Pipes with galvanized inner surfaces are not allowed in the fresh water cooling system. Some

cooling water additives react with zinc, forming harmful sludge. Zinc also becomes nobler

than iron at elevated temperatures, which causes severe corrosion of engine components.

Ships (with ice class) designed for cold sea-water should have provisions for recirculation

back to the sea chest from the central cooler:

●

For melting of ice and slush, to avoid clogging of the sea water strainer

●

To enhance the temperature control of the LT water, by increasing the seawater temperature

9.3.2

Stand-by circulation pumps (4P03, 4P05)

Stand-by pumps should be of centrifugal type and electrically driven. Required capacities and

delivery pressures are stated in Technical data.

NOTE

Some classification societies require that spare pumps are carried onboard even

though the ship has multiple engines. Stand-by pumps can in such case be worth

considering also for this type of application.

9.3.3

Sea water pump (4P11)

The sea water pumps are always separate from the engine and electrically driven.

The capacity of the pumps is determined by the type of coolers and the amount of heat to be

dissipated.

Significant energy savings can be achieved in most installations with frequency control of the

sea water pumps. Minimum flow velocity (fouling) and maximum sea water temperature (salt

deposits) are however issues to consider.

9.3.4

Temperature control valve, HT-system (4V01)

External HT temperature control valve is an option for V-engines.

Wärtsilä 32 Product Guide - a21 - 7 September 2016

9-13

9. Cooling Water System

Wärtsilä 32 Product Guide

Summary of Contents for WARTSILA32

Page 18: ...This page intentionally left blank...

Page 72: ...This page intentionally left blank...

Page 130: ...This page intentionally left blank...

Page 150: ...This page intentionally left blank...

Page 186: ...This page intentionally left blank...

Page 204: ...This page intentionally left blank...

Page 210: ...This page intentionally left blank...

Page 216: ...This page intentionally left blank...

Page 238: ...This page intentionally left blank...

Page 246: ...This page intentionally left blank...

Page 248: ...This page intentionally left blank...

Page 251: ......

Page 252: ......

Page 253: ......