32

Installation manual

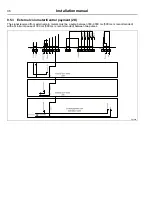

9.3

Three-phase connection

Demount the cover panel from the supply unit. Connect the earth and other wires as shown.

3AC

3AC

L1

L2

L3

3NAC

3NAC

L1

L2

L3 N

When the installation is completed remount the cover panel and check:

• That the drum is empty.

• That the machine operates by connecting the power to the machine and start a program with heat.

Summary of Contents for D7-550

Page 1: ...Installation manual Tumble dryer D7 550 Type N2 Original instructions 438905413 EN 2023 02 27...

Page 2: ......

Page 4: ......

Page 42: ......

Page 43: ......