- 30 -

Symptom

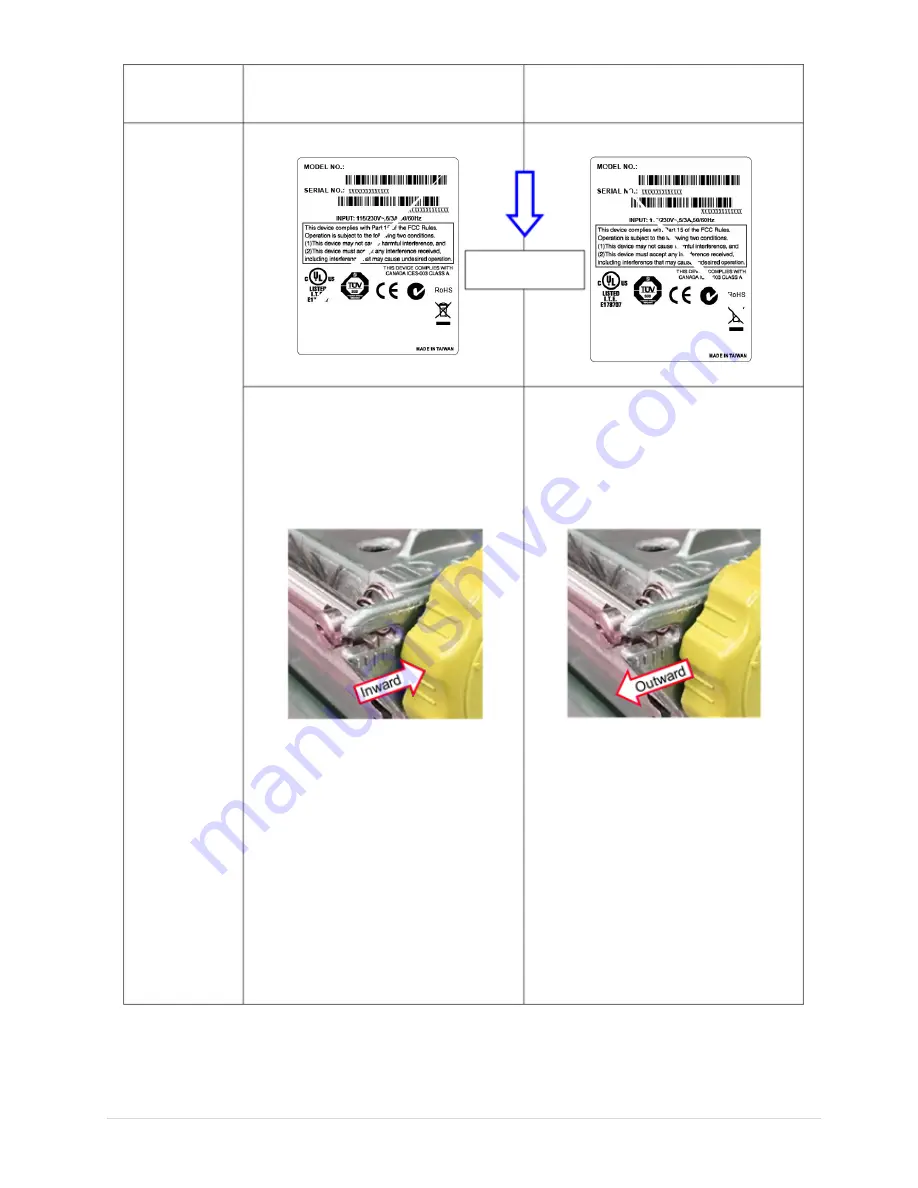

1. Wrinkle happens from label lower

left to upper right direction (“

ˊ

”)

2. Wrinkle happens from label lower

right to upper left direction (“

ˋ

”)

Feed direction

If the wrinkle on the label starts from the

lower left side to upper right side, please do

following adjustment.

1.

Switch the ribbon tension adjustment

knob clockwise per 1 level and print the

label again to check if the wrinkle is

gone.

If the wrinkle on the label starts from the

lower right side to upper left side, please do

following adjustment.

1.

Switch the ribbon tension adjustment

knob counterclockwise per 1 level

and print the label again to check if

the wrinkle is gone.

Wrinkle Example

2.

If the ribbon tension adjustment knob

has positioned on the level of innermost

side but didn’t improve the ribbon

wrinkle, please switch the print head

pressure position adjustment knob per 1

level and print the label again to check if

the wrinkle is gone.

3.

If the ribbon wrinkle still can’t improve

after switch the print head pressure

position adjustment knob, please adjust

the print head pressure adjustment knob

per 1 level again to check if the wrinkle

is gone.

2.

If the ribbon tension adjustment

knob has positioned on the level of

outermost side but didn’t improve

the ribbon wrinkle, please switch

the print head pressure position

adjustment knob per 1 level and

print the label again to check if the

wrinkle is gone.

3.

If the ribbon wrinkle still can’t

improve after switch the print head

pressure position adjustment knob,

please adjust the print head

pressure adjustment knob per 1

level again to check if the wrinkle is

gone.