P

remises

© CSP S.r.l.

1

8

1

General information

1.3. Testing

The printer is tested directly by the Manufacturer during the phase of mounting and post mounting.

1.4. Warranty

The printers built by CSP S.r.l. are covered by a warranty for a period of 12 months for companies or VAT and 24

months for individuals.

If during the period of validity, defective operations or faults of parts of the printer that fall within the cases

indicated in the warranty occur, CSP S.r.l. (after the appropriate checks) will repair or replace the defective parts.

The defective parts under warranty are repaired or replaced free of charge by CSP S.r.l. .

The costs of transport and / or shipment are always charged to the Customer, as well as the return / return travel

expenses related to the intervention of the Manufacturer’s technicians at the Customer’s premises.

The labor costs related to the intervention of the Manufacturer’s technicians at the Customer’s premises, for the

removal of defects under warranty are the responsibility of the Manufacturer, except in cases where the nature

of the defect is such that it can be easily removed on site by part of the Customer.

All consumables are excluded from the warranty, possibly supplied by the manufacturer together with the

machines.

NOTE:

The guarantee lapses in the following cases:

• In case of default or other contractual non-fulfillment;

• Improper use of the printer

• Failure to comply with the standards and maintenance intervals

• Tampering

• The printer is returned to the Manufacturer in a different packaging from the one supplied at the

time of purchase;

• Use of non-original spare parts, ie not supplied directly by the Manufacturer;

• Extraordinary interventions not carried out by personnel not sent by the Manufacturer;

• Any variation and / or non-observance of what is indicated in the technical documents and in

this manual entails the forfeiture of the technical and functional guarantees, and release the

Manufacturer of the printer from any responsibility.

1.2.1. Position of the label on the printer

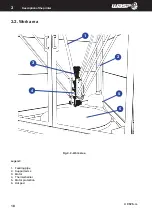

Summary of Contents for Delta WASP 3MT INDUSTRIAL 4.0 LDM

Page 1: ...MANUAL OF USE AND MAINTANANCE ORIGINAL INSTRUCTIONS ...

Page 4: ......

Page 12: ...Premises CSP S r l 1 12 1 General information Legend Hot surfaces do not touch risk of burns ...

Page 51: ...Premises CSP S r l 51 Ordinary and extraordinary maintanance 7 ...

Page 69: ...fig 8 10 o fig 8 10 p fig 8 10 q Premises CSP S r l 8 69 Use of the printer 8 ...

Page 71: ...fig 8 12 a fig 8 12 b Premises CSP S r l 8 71 Use of the printer 8 ...

Page 73: ...Premises CSP S r l 8 73 Use of the printer 8 ...

Page 85: ...Premises CSP S r l 8 85 8 Fig 8 13 Change the extruder Multi core ...