Wasp R500 Pro-Rally Kart.

Assembly Steps 17 - 28.

Step Twenty-Seven

Fit the aluminium foot plate

4 x M8 x 20 soc caps,

M8 washers & M8 nylocks.

Fill the engine with

recommended oil & fuel

(See engine manual).

Check all

the nuts & bolts are tight & all

the controls operate freely & fully as intended

(Stop switches,

brakes steering Etc.).

Fit the foam padding to the cockpit area ,

(steering

column upright, roll bar, side rails, etc.)

to help protect the

driver from any possible contact with the structure of the kart

during its operation. This can be easily cut with a hacksaw to

the correct lengths & secured with tie wraps or tape.

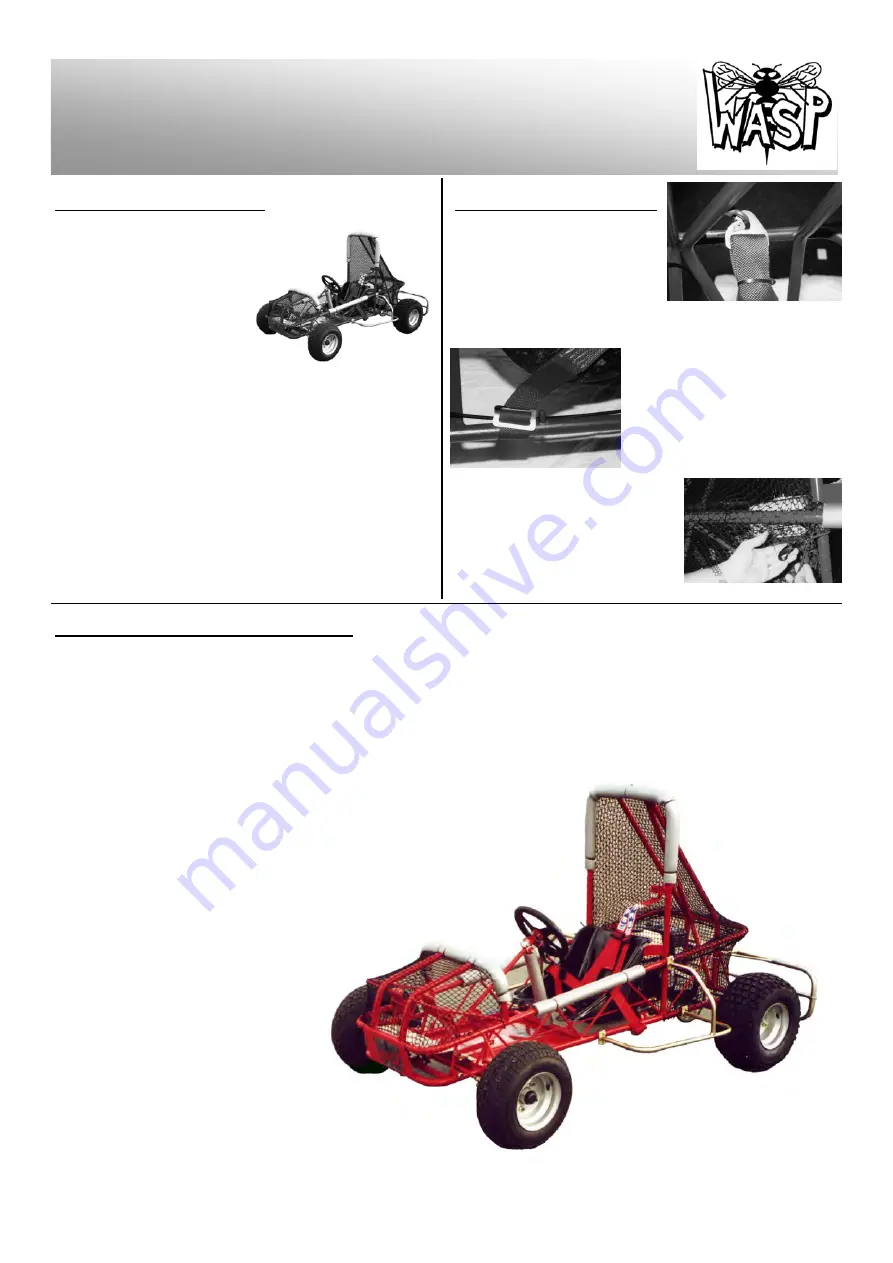

Step Twenty-Eight

Fit seat harness to the rear roll

frame support (steel eye) & the

webbing to the side rails behind

the lugs provided.

(Make sure the

harness fits the driver correctly &

it does not interfere with any of the controls or kart

components.)

Warning! All the excess webbing

should be tie wrapped neatly &

securely to itself & under no

circumstances allowed to dangle

loose.

Thread the two bungy lengths

through the top of the bottom netting

skirt and through the bottom edge of

the roll bar net.

Secure each end around on itself,

wrapping around the roll bar upright.

Wasp R500 Pro-Rally Kart.

On completion of your kart it is highly recommended that the driver & kart supervisor read the

Inspection & Maintenance Guide & The Driver & Supervisor Instructions

which comes with this

assembly manual.

The kart will need careful attention in its early hours as it runs in. Keep a constant check on all fixings,

adjustments & lubrication.

Please note that the brake will not

operate at its fullest potential as

the pads bed into the disc. Do not

push the kart during this period.

But allow it to settle in slowly.

To maintain good, long lasting,

safe performance all parts should

be checked & inspected every-

day, lubricated with the correct

lubricants & serviced regularly.

It is recommended that the

completed kart is checked over by

a qualified engineer before use.