8

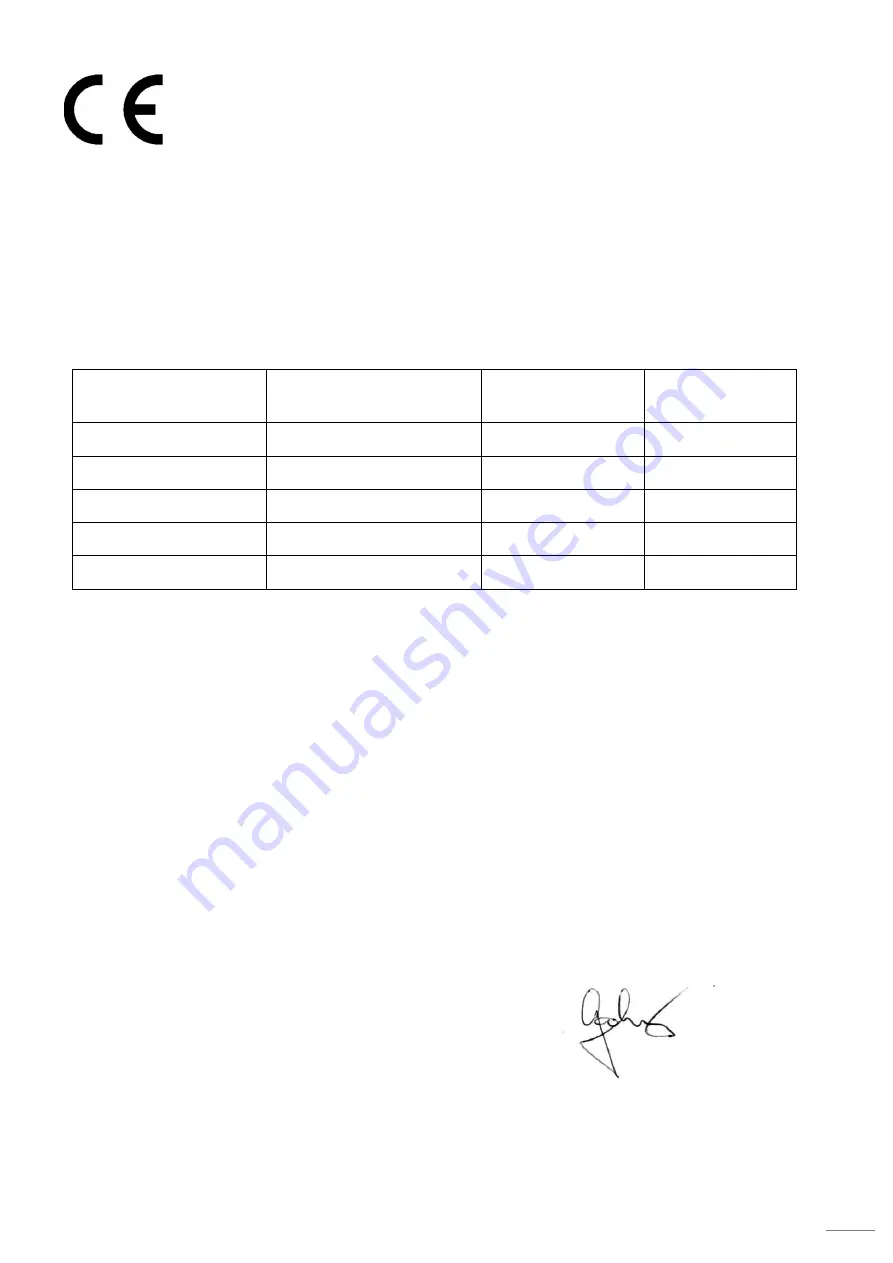

EU Declaration of Conformity

The company Waspper s.r.o. hereby declares that the water pumps defined below comply with the

relevant EU directives on occupational health and safety of the device operators. Any alteration of the

device without the prior consent from the manufacturer will render this declaration void.

Product details: Water pump

TYPE

Inspection reports

Noise level

measured

Guaranteed noise

level

WP15

4597/3/2019

96dB

98dB

Certificate issued by:

TECHNICKÁ INŠPEKCIA a.s., pracovisko KOŠICE, as an accredited inspection body in

accordance with EN ISO / IEC 17020

Applicable EU Directives:

2006/42/ES (+2009/127/ES)

2004/108/ES

2000/14/ES

Standards applied:

STN EN ISO/IEC 17 020

Producer:

Waspper s.r.o, Duklianska 51, 05201 Spišská Nová Ves, Slovensko

Issued in: Spišská Nová Ves Manufacturer's representative: Marián Garbriš

Issue date: 25.9.2019 Position: Managing Director