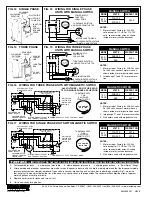

ELECTRICAL CONNECTIONS

All electrical connections must be made in accordance with local wiring codes

Flexible BX cable should be used in making electrical

connections to motor to avoid transmission of noise.

Be careful not to pinch wires when replacing terminal box.

IMPORTANT! THE WASTE KING COMMERCIAL DISPOSER MUST BE CAREFULLY

AND PERMANENTLY GROUNDED. GROUND SCREW IS PROVIDED.

Overload Protection: Reset button overload provided on all standard models.

IMPORTANT NOTE: Disposer motor phase, single or three phase, must be the same as power source and line phase.

Disposer wiring connection voltage must be the same as the voltage of power source.

ALL SINGLE PHASE MOTORS

3-Pole, 20 Amp., heavy duty switch encased in waterproof receptacle. Two poles of switch control motor and third pole controls solenoid, isolat-

ing the two circuits to prevent solenoid kickback when switch is turned off. Refer to Figures 12 and 13 for recommended wiring installation.

SINGLE PHASE 1/2 HP

Factory Wired for 110-120-V A.C. unless otherwise specified. To connect for 220-240-V A.C. refer to information on inside face of

terminal box cover.

SINGLE PHASE

3

/

4

HP, 1HP, 1

1

/

4

HP, and 1

1

/

2

HP

Factory Wired for 220-240 volts. To reconnect for 110-120 volts refer to information on inside face of terminal box cover.

NOTE: After installation, be sure turntable rotates clockwise.

CAUTION

: When making field changes for voltage, be certain to change all other related electrical circuits such as solenoid valves, relays, etc.

ALL THREE PHASE MOTORS

3-Pole, 20 Amp., heavy duty switch encased in waterproof receptacle. Tap off any two leads for the solenoid valve. Refer to Fig. 14 and 15 for

typical wiring installation.

THREE PHASE

3

/

4

HP, 1HP, 1

1

/

4

HP, and 1

1

/

2

HP

All three phase motors are factory wired for 208-240-V A.C.

AFTER INSTALLATION BE SURE TURNTABLE ROTATES CLOCKWISE

. If not,

interchange any two of the three wires. To reconnect for 460 volts, refer to information shown on inside face of terminal box cover.

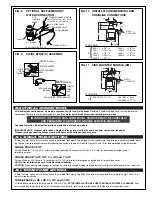

FIG. 8

OPTIONAL SUPPLEMENTARY

WATER CONNECTION

FIG. 10

INSTALLATION DIMENSIONS AND

DRAINLINE CONNECTIONS

FIG. 9

SWIRL SPRAY(S) ASSEMBLY

FIG. 11

SINK MOUNTED MODELS (SM)

500-1

= 18

7

/

16

1250-1

= 19

11

/

16

750-1

= 18

15

/

16

1250-3

= 18

15

/

16

750-3

= 18

7

/

16

1500-1

= 19

11

/

16

1000-1

= 18

15

/

16

1500-3

= 18

15

/

16

1000-3

= 18

7

/

16

FLOOR LINE

500-1SM = 17

11

/

16

750-1SM = 18

3

/

16

750-3SM = 17

11

/

16

FLOOR LINE

TOGGLE SWITCH

1/2” ELBOW

CLAMP

1” I.D.

FLEXIBLE

HOSE

1/2” GLOBE VALVE

SYPHON BREAKER MUST be

above Table Floor Level. Check

local code for confirmation.

1/2” SOLENOID VALVE

1/2” COLD WATER SUPPLY

JUNCTION BOX

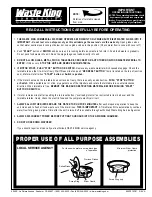

AERATOR SPRAY

SPRAY GASKETS

STEEL WASHER

CONICAL –

BRASS WASHERS

NUT

LOCK

NUT

TUBING

LOCK

NUT

TUBING

NUT

STEEL WASHER

SPRAY HEAD

BRASS

WASHERS

SPRAY HEAD

GASKET

2

1

/

2

”

3

1

/

2

”

8

1

/

2

”

A

7

3

/

4

”

8

15

/

16

”

1

1

/

8

”

SLOPE =

1

/

4

” PER FOOT

3

9

/

16

”

3”

6”

8

1

/

2

”

A

7

3

/

4

”

8

15

/

16

”

2

5

/

32

”

SLOPE =

1

/

4

” PER FOOT

3

9

/

16

”

CONICAL

WASHER

{

{

A

A