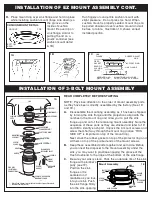

INSTALLATION OF EZ MOUNT ASSEMBLY CONT.

SUPPORT RING

SINK

FIBER

GASKET

MOUNT RING SHOULD BE

FREE TO MOVE UP & DOWN

OPEN AREA, NO

OBSTRUCTION

SINK FLANGE

BEAD OF

CUSHION

MOUNT

1A

1B

1C

RUBBER GASKET

SINK

FLANGE

H.

Place mount ring over sink flange and hold in place

while installing cushion mount (large side down) so

the groove on the

inside of cushion

mount fits over lip on

sink flange, similar to

putting the lid on a

plastic container (see

cushion mount detail

& 1B).

Run fingers around entire cushion mount with

slight pressure. Do not press too hard. When

cushion mount is properly seated, mount ring can

be pulled downward over cushion mount and will

be free to rotate. Illustration 1C shows correct

installed position.

TOP

BOTTOM

BEAD

GROOVE

CUSHION MOUNT DETAIL

NOTE: Pay close attention to the order of mount assembly parts,

as they have been correctly assembled by the factory. (See 1D

and 1E.)

A.

Disassemble the mounting assembly, as it has been shipped,

by turning the sink flange until the projections align with the

notches in the mount ring and allow you to pull the sink

flange up and out of the remaining mount assembly. Note the

sequence of these parts as they are stacked and refer to 1D

and 3B to identify each part. Unpack the 3 mount screws and

screw them half way through the mount ring (notice “THIS

SIDE UP” is imprinted on top of the mount ring).

Next, stack the rubber gasket on top of the protector ring and

sit them on top of the pointed ends of the mount screws.

B.

Keep these assembled parts together and set aside. Before

you connect the disposer to the mount assembly under the

sink, you may want to practice engaging the groove of the

Hush Cushion® to the ridge at the bottom of the sink flange.

C.

Be sure your sink is clean. Pack the underside rim of the sink

flange with plumberʼs

putty (see 1F).

Position the sink

flange so it is

centered and

readable as you look

into your sink. Push

the sink flange firmly

into the sink opening

READ COMPLETELY BEFORE STARTING

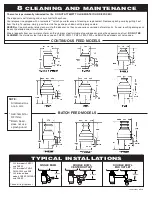

INSTALLATION OF 3-BOLT MOUNT ASSEMBLY

1D

STOPPER*

SINK FLANGE**

SINK

HOPPER

ELBOW

GASKET

SCREWS

SERIAL #- RECORD ON

WARRANTY CARD

MOUNTING

SCREWS**

SCREW

CLAMP**

PROJECTIONS

RIDGE

RIDGE

DISCHARGE

ELBOW

ELBOW

FLANGE

DISHWASHER

DISCHARGE INLET

HUSH CUSHION

®

**

RUBBER SINK

FLANGE GASKET**

PROTECTOR RING**

MOUNT RING**

PLUMBER’S

PUTTY

END BELL

(ELECTRICAL

CONNECTIONS)

MOUNTING

SCREWS

PROTECTOR

RING

RUBBER

GASKET

SINK

FLANGE

HUSH CUSHION

1E

SCREW

CLAMP

MOUNTING

RING

Mount Assembly

*

Batch Feed Stopper looks different than the stopper illustrated.

** Mount Assembly (see 3B)