www.watchgas.eu

11

D e t e c t i o n

User Manual

Single Sustainable Gas Detector PDM+

D e t e c t i o n

6.2. BUMP TEST

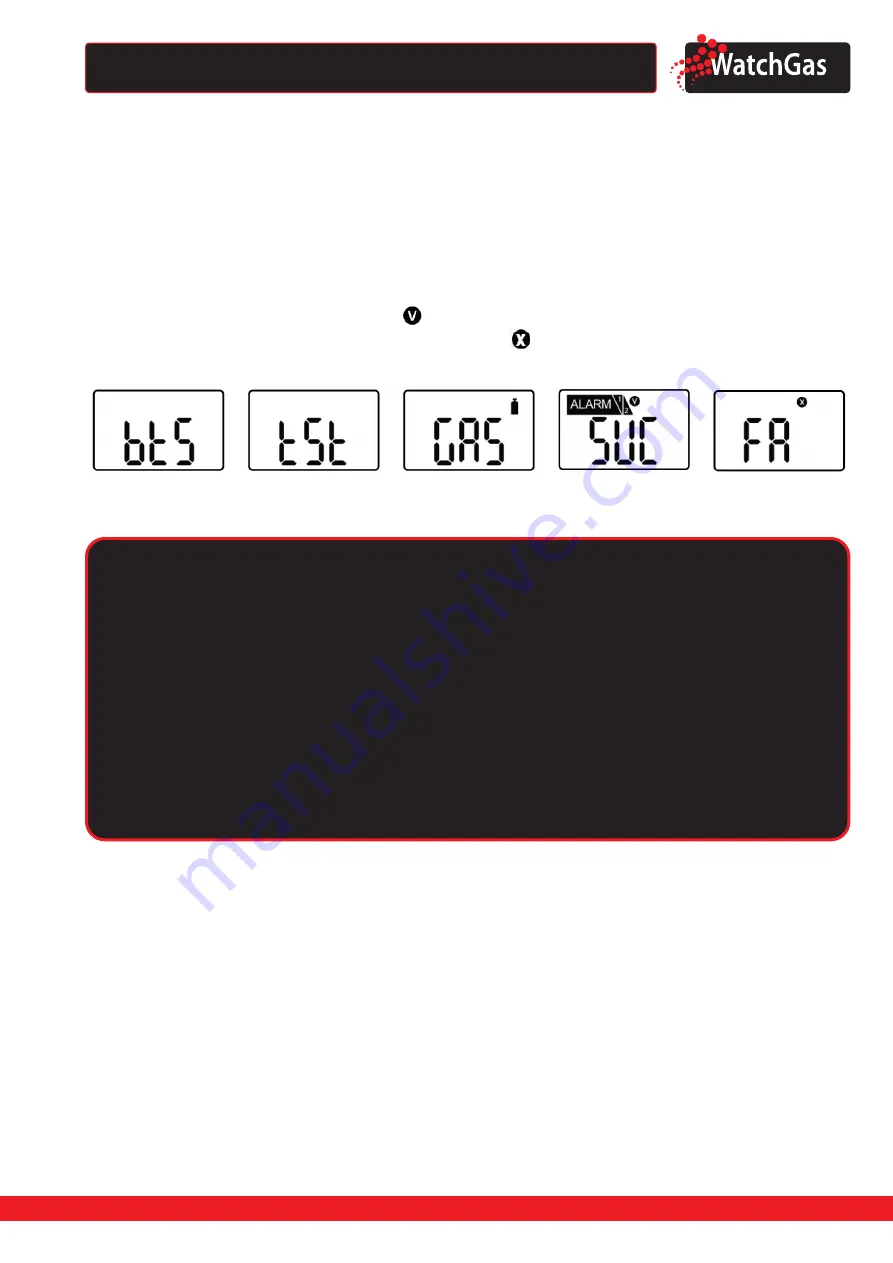

The interval of Bump test is 1~365days, and the default is switched off. To initiate the bump test, set

the bump test interval. Once the bump test interval expires, Bts message will flash.

Put the PDM+ in the docking station with a valid and full gas cylinder. Alternatively, attach the

calibration adapter to PDM+ and a valid and full gas cylinder. Press and hold the key for 3 seconds, the

TST message will be displayed for 45 seconds (To cancel, press the button for one second). Within the

45 seconds, start the flow from the gas cylinder. If no gas is applied, the bts message will flash again.

If the test is successful, SUC message with

will be displayed for 30 seconds. Stop the flow, remove

the calibration adapter. If the test fails, FA message with , will be displayed and BTS message will be

flashing until the test is successful. If the bump test repeatedly fails, contact WatchGas.

7. Sensor & Battery Replacement

Caution

It is absolutely prohibited to replace battery at potential explosion or dangerous regions.

Replace the battery in a clean environment, which has no hazardous gases.

Replacement of components can invalidate the intrinsic safety function.

Replacing the sensor and battery should be performed by authorized sellers, agents,

distributors, or managers. Contact WatchGas if replacement is needed.

Disassembly should be necessary only for sensors & battery replacement. After the sensor

replacement, Fresh air and SPAN calibration should be done. Before disassembling, please

turn off the power and remove screws.

Only use SB-AA02 3.6V battery.

7.1. SENSOR REPLACEMENT

1. Deactivate the detector

2. Remove the 6 screws on the back case and carefully open te case.

3. Remove the 2 screws on the PCB board.

4. After removing the battery, replace with the new sensor matching with the gas type. For instance,

If you have the PDM+ CO, the CO sensor should be used for the replacement.

5. Assemble the detector.

6. Have the sensor stabilized for 5 minutes before use.

7. After assembling, perform the fresh air calibration and standard calibration with the concentration

in this manual.

8. Check the settings.