3

23833A157

Warranty void if product modified, drilled, painted,

or altered in any way; if used to pump hot water, or

to pump liquids other than water (such as but not

limited to chemicals, fertilizers, flammable liquids, herbicides,

mud, tar, cement, wood chips); or otherwise abused.

Rules for Safe Installation and Operation

When installing and using this electrical equipment, basic safety

precautions should always be followed, including the following:

1. READ THESE RULES AND INSTRUCTIONS CAREFULLY.

Failure to follow them could cause serious bodily injury and/or

property damage.

2.

WARNING.

To reduce the risk of injury, do not permit children

to use or operate this product.

3.

WARNING.

Risk of electric shock. Connect only to a circuit

protected by a ground fault circuit interrupter (GFCI). Contact a

qualified electrician if you cannot verify that the receptacle is

protected by a GFCI.

4.

Check National Electric Code and state and local codes before

installing. You must comply with these rules.

5.

Before installing pump, have the electrical circuit checked by

an electrician to make sure it is properly grounded.

6.

Before installing or servicing your pump, BE CERTAIN pump

power source is disconnected.

7.

Match supply voltage to nameplate voltage. Wrong voltage can

cause fire or motor damage and voids warranty. If in doubt, consult

a licensed electrician.

8.

Complete pump and piping system must be protected against

below-freezing temperatures. Failure to do so could cause severe

damage and will void the warranty.

9. WARNING.

Do not pump chemicals or corrosive liquids with

this pump. To do so will shorten the life of pump seals and moving

parts, voiding the warranty.

10.

After carefully removing your pump from the carton, make a

visual inspection for any apparent shipping damage.

11.

Do not use extension cords.

12.

Do not pump gasoline or other flammable liquids.

13.

If you need to close the valve on the discharge side of the

pump, shut the valve slowly. Rapid closing of the valve could cause

a water hammer effect and damage the pump.

14. SAVE THESE INSTRUCTIONS.

Pump must be primed! Make sure pump is full of water before

running! Failure to do so will cause damage to mechanical seal,

leakage and flooding.

WARNING. Explosion hazard.

Never run pump against closed

discharge valve! To do so can cause high temperatures, pump

damage, personal injury and property damage.

WARNING. Hazardous voltage!

Can shock, burn or cause death.

Read instructions before installing. To avoid dangerous or fatal

shock hazard, turn off power and ground motor before connecting

motor to electrical power supply. Do not ground to a gas supply

line.

Pump may be HOT to touch. Use caution.

IMPORTANT INSTRUCTIONS BEFORE INSTALLATION

Failure to follow these instructions may cause serious bodily injury and/or property damage.

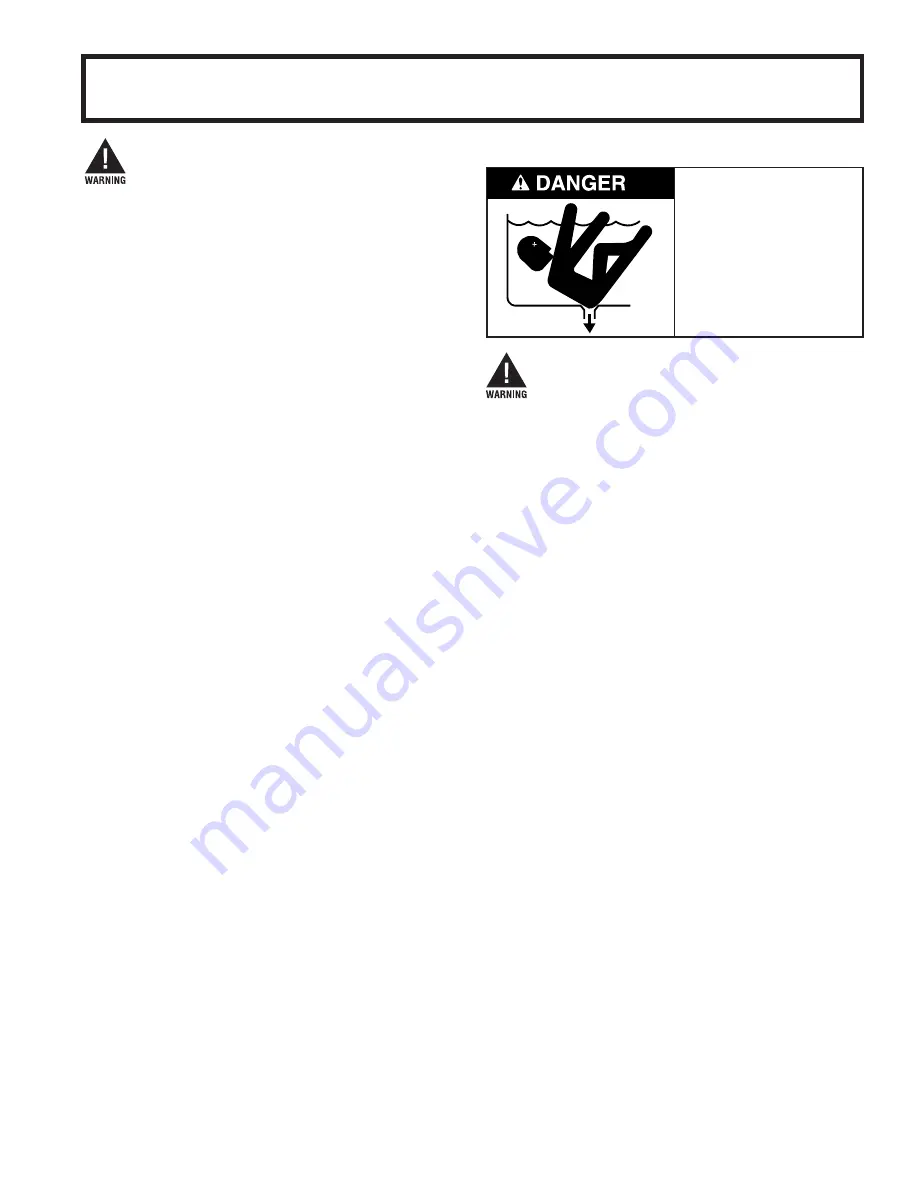

POOL PUMP SUCTION REQUIREMENTS

Pump suction is hazardous and can trap and drown or

disembowel bathers. Do not use or operate swimming

pools, spas, or hot tubs if a suction outlet cover is

missing, broken, or loose.

Follow the guidelines below

for a minimimum risk installation.

Suction Outlet Covers

All suction outlet covers must be maintained, and replaced if

cracked, broken, or missing. See “Testing/Certification”, below, for

outlet cover certification requirements.

All suction outlets must have correctly installed, screw-fastened

covers in place.

Suction Outlets Per Pump

Provide at least two hydraulically balanced main drains, with

covers, as suction outlets for each circulating pump suction

line. The centers of the main drains (suction outlets) on any one

suction line must be at least three feet apart.

The system must be built so that it has at least two main drains

connected to the pump whenever it is running (see “Typical

Installation Drawing”, Page 4). However, if two main drains

run into a single suction line, that line may be equipped with a

valve to shut off both main drains from the pump (see “Typical

Installation Drawing”).

More than one pump can be connected to a single suction line as

long as the requirements above are met.

Testing/Certification

Suction outlet covers must have been tested by a nationally

recognized testing laboratory and found to comply with the latest

ASME/ANSI A112.19.8 Standard Specification for Suction Fittings

For Use in Swimming Pools, Spas, Hot Tubs, and Whirlpool Bathtub

Applications.

Hazardous Suction.

Can trap hair or body,

causing severe injury

or death.

• Do not block suction.

• Keep small children

under close adult

supervision at all times.

4078 1001 IG