6

water pressure at the conditioner is not less than 40 psi

(2.8 bar). You may elevate an additional 2 feet (61 cm)

for each additional 10 psi (0.7 bar).

Where drain line is elevated but empties into a drain

below the level of the control valve, form a 7-inch

(18-cm) loop at the far end of the line so that the bottom

of the loop is level with the drain line connection. This

will provide an adequate siphon trap (Figure 5).

Where a drain empties into an overhead sewer line, a

sink-type trap must be used.

IMPORTANT:

Never connect the drain line into a drain,

sewer line, or trap. Always allow an air gap between the

drain line and the wastewater to prevent the possibility

of sewage being back-siphoned into the conditioner.

Note:

Standard commercial practices have been

expressed here. Local codes may require changes to

these suggestions.

Brine Line Connection

Install an appropriate fitting onto the 1/4-inch male NPT

connection on the air check, Figure 7, and install a

length of flexible tubing between the air check fitting

and the brine pickup tube at the brine tank.

Note:

Make sure that all fittings and connections are

vacuum tight so that premature checking does not take

place. Premature checking occurs when the ball in the

air check falls to the bottom before all brine is drawn

out of the brine tank. Refer to the Troubleshooting

section in this manual for additional information.

Brine Tank Overflow Line Connection

In the event of a malfunction, the brine tank overflow

connection directs overflow to the drain instead of

spilling it on the floor where it could cause water

damage. Complete the following steps to connect the

overflow fitting to the brine tank:

1. Locate the fitting hole on the side of the brine tank.

2. Insert the overflow fitting (not supplied) into the

tank and tighten with the plastic thumb nut and

gasket as illustrated in Figure 6.

3. Attach a length of 1/2-inch (1.3-cm) tubing (not

supplied) to the fitting and run to the drain.

Figure 6 - Overflow Line Connection

Note:

Do not elevate the overflow line higher than

3 inches (7.6 cm) below the bottom of the overflow

fitting. Do not tie into the drain line of the control unit.

The overflow line must be a direct, separate line from

the overflow fitting to the drain, sewer, or tub. Allow an

air gap as in the drain line connection, Figure 5.

Placing Conditioner into Operation

Initial Start-Up

After the water conditioning system is installed, the

conditioners should be disinfected before they are

used to treat potable water. Refer to the Disinfection of

Water Conditioners

section in this manual. Complete

the following steps to place the conditioner into

operation:

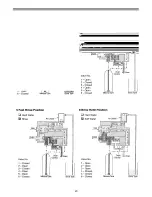

1. Remove the rear valve cover by pulling back on the

tab located on the lower rear edge of the cover.

Next, lift the cover off the valve, Figure 10.

2. Grasp the camshaft and rotate it

COUNTERCLOCKWISE

(as viewed from the front

of the control) until the indicator on the

regeneration cycle indicator points directly to the

word BACKWASH.

3. Fill the mineral tank with water. Turn the water

supply off and place the bypass valve(s) into the

“not in bypass” position. Open the water supply

valve very slowly to approximately the 1/4 open

position.

IMPORTANT:

If the water supply valve is opened too

rapidly or too far, resin may be lost. In the BACKWASH

position, you should hear air escaping slowly from the

drain line.

4. When all of the air is purged from the tank (water

begins to flow steadily from the drain), slowly open

the main supply valve all the way. Allow the water

to run into the drain until clear. Turn off the water

supply and wait for about five minutes to allow all

trapped air to escape from the tank.

Brine Tank

Overflow Fitting

Installed

Connect 1/2-in. (13 cm)

I.D. Tubing or Hose and Run

to Drain