8

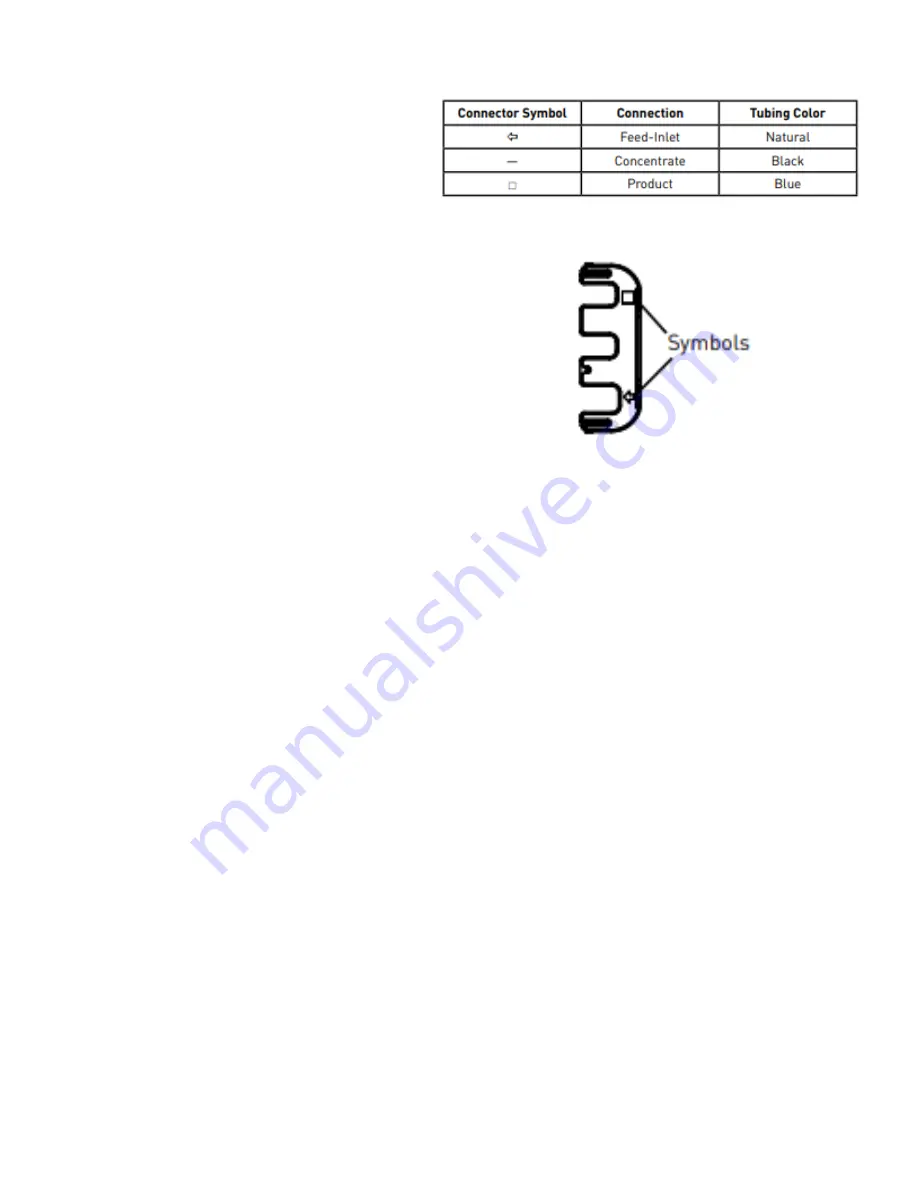

9. Figure 3 details the coding system for the fitting

connections. Each fitting has a unique “keyed”

socket on the manifold. Each fitting also has a

graphic symbol molded into the elbow with a

corresponding symbol on the manifold. The

locking clip also has the same markings (Figure 4).

10. Insert the float switch wire (located on top of the

storage tank) through one of the open cord grips

on the control panel.

11. Land the (2) float switch wires on their appropriate

terminals. The appropriate terminals are 7 & 8.

Either wire can be landed on either terminal. Polarity

does not matter. For additional wiring information,

see appendix B and C.

12. Connect the plastic tubing (located on top of the

storage tank) to the ozone generator output. The

ozone generator output is located on the bottom of

the ozone generator.

13. Connect the blue 3/8” tubing from the permeate outlet

on the skid assembly to the connection on the top of

the storage tank.

START-UP STEPS

1.

Once all plumbing connections are completed, and the system is plugged in, check to make certain the drain flow control

valve (gray valve with black circular handle), is in the fully open position.

2.

For WHRO-700MAX systems only, open the filter inlet valve and depress the air purge button located on the top of the tank

until a steady stream of liquid comes out of the cartridge. As the cartridge fills up with water, air will be vented while the air

purge button is depressed. After a steady stream of liquid comes out of the filter, open the filter outlet valve.

3.

PRESSURIZE: Turn the control switch on the control panel to “Run”. This will open the motorized ball valve.

4.

PRESSURIZE: Slowly open the feed valve to the RO system. As the system begins to pressurize, you will notice air bubbles

in the DRAIN and PRODUCT flow meters and the pressure will begin to rise.

5.

PRESSURIZE: Slowly increase the amount of water feeding the RO system until the feed valve is completely open. At this

point, most of the water should be passing through the DRAIN flow meter. Allow the system to run this way for at least 30

minutes. This will flush the membranes.

6.

CHECK FOR LEAKS: During this initial start-up time, check for leaks. As a result of shipping, it is possible that some of the

fitting and tubing connections could be loose.

7.

CHECK FOR LEAKS: Once you have checked for leaks and corrected all you have found, adjust the drain flow control valve

so that the DRAIN flow and PRODUCT flow ratio is in line with Table 2.0 in the “System Recovery” section.

8.

FILL TANK: At this time, the storage tank is slowly filling with RO purified water (PRODUCT WATER). On a standard system,

the production rate is approximately 0.50 GPM. In order to test the pump and make certain the tank is clean, consider adding

tap water to the tank so that it is at least ½ full.

9.

PRIME PUMP: Once the water level in the tank is above the top of the pump, prime the pump. To do this, open the tank outlet

valve and, with the power to the pump turned off, slowly unscrew the air relief port on the top of the pump. If there is enough

water in the storage tank, water will begin to spew out of the port. Allow sufficient water to pour out to make certain no air

remains in the pump. Close the tank valve, screw the port cap back on the pump, and open the tank valve.

NOTE: If the pump does not prime by the method described above, water may be manually added to the priming port to

fill the entire pump cavity with water.

10.

TEST FLOAT: While you continue to add water to the storage tank, reach inside the tank and manually lift the float. With the

float elevated toward the top of the storage tank, the motorized valve should close cutting off the water supply to the system.

Repeat this step 3 to 4 times to confirm the system successfully turns on and off. This can be observed by:

a.

No more water entering the storage tank

Figure 4

Figure 3

Summary of Contents for WHRO-700

Page 2: ...2 This page intentionally left blank...

Page 5: ...5 SYSTEM DIAGRAM...