9

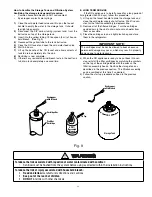

M. FLUSH THE APPLIANCE OF THE PRESERVATIVE

AND CHECK THE OPERATION

1) With the tank valve closed (the tank should still contain the

sanitizing solution at this point), open the faucet (set the

faucet handle in the “up” position) and feed water valve.

Water should begin to drip from the faucet within several

minutes. Continue to flush the system for 24 hours. Water

will steadily drip from the faucet at this time. During this

procedure, the tank is being intentionally bypassed in

order to thoroughly sanitize the tank and also flush the

membrane of any preservatives.

To reduce the risk associated with irritation from Sodium Metabi-

sulfite during installation:

•

Sodium Metabisulfite (CAS 07681-57-4) is used in a

1% preservative solution within the reverse osmosis

membrane.

•

Do not put this system into service before the RO

tank is flushed as specified in the installation instruc-

tions. Wear eye and face protection during installa-

tion.

•

To request an MSDS relating to this product, call 203-

238-8965 or visit the web at http://solutions.3m.com/

wps/portal/3M/en_US/MSDS (click MSDS search). For

emergencies, call 800-364-3577 or 651-737-6501 (24

hours).

2) After flushing for 24 hours, shut off the faucet. Open the tank

valve, lift the faucet handle again and allow the tank to

completely empty. When the tank is empty, the faucet will

drip steadily. Measure and record the rate at which water

drips from the faucet. Use a graduated cylinder (in

milliliters) and a watch with a second hand to calculate the

approximate production in gallons per day (milliliters per

minute x 0.38 = gpd). Proceed to check the reject flow by

disconnecting the tubing at the drain connection and

measuring the drip rate as outlined above. The ratio

should be a minimum of 2.5 (reject) to 1 (product).

Repeat every 5 minutes until the rate is constant. When

the rate is constant, the tank is empty.

3) Allow the system to operate in this condition for 24 hours.

4) Close the faucet and reinspect the appliance for leaks.

Allow the tank to fill completely (it will take approximately

4 hours), then drain the tank again.

The water should be

discarded because it may contain some sanitizing solu-

tion.

5) The appliance should be ready to use as soon as the tank

refills. If any objectionable taste is noticed after the

second tankful is drained, instruct the customer to wait

and drain the tank the following day. Only at this time

should an icemaker be turned on if one is connected to

the appliance.

N. CLEAN UP AND PAPERWORK

1) Clean up the work area thoroughly.

2) Fill out the warranty card and return it.

For replacement parts and filters, please contact your dealer

or call Water Factory Systems at 1-800-733-1199 or visit our

website at www.waterfactorysystems.com.

This system has been tested for the treatment of water contain-

ing pentavalent arsenic (also known as As(V), As(+5), or arse-

nate) at concentrations of 0.30 mg/L or less. This system treats

pentavalent arsenic, but may not affect other forms of arsenic.

This system is to be used on water supplies containing a detect-

able free chlorine residual or on water supplies that have been

demonstrated to contain only pentavalent arsenic. Treatment

with chloramine (combined chlorine) is not sufficient to ensure

complete conversion of trivalent arsenic to pentavalent arsenic.

Please see the Arsenic Facts section of the Performance Data

Sheet for further information.